Description

Introduction:

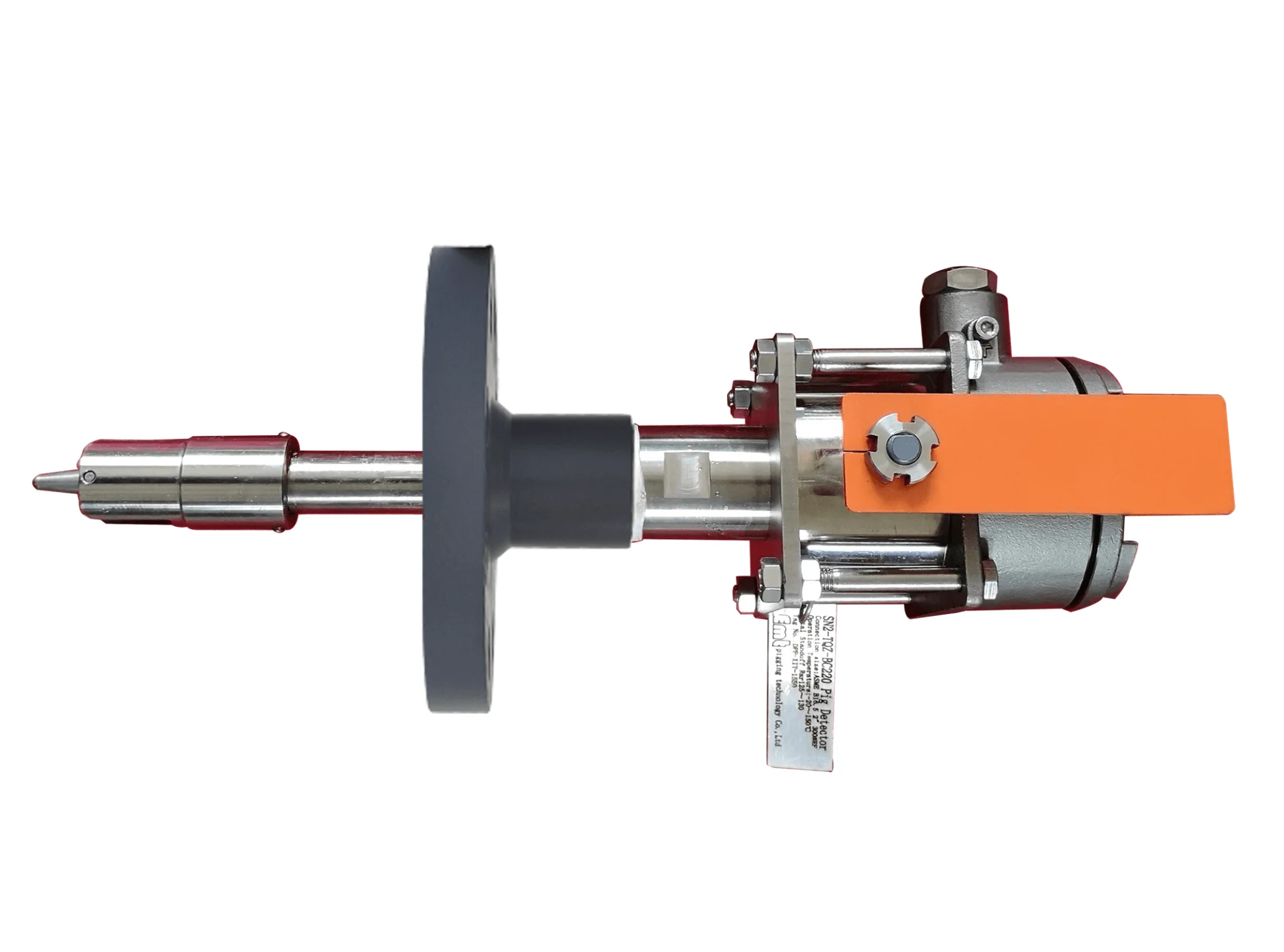

In the oil and gas industry, the efficient operation of pipelines is critical to maintaining smooth and uninterrupted production. Pipelines typically require regular cleaning to remove debris, wax, and other contaminants that can impede the flow of oil and gas. The 2-inch flange connection to the pig signaller plays a crucial role in this process, providing a reliable way to detect the passage in the pipeline for cleaning the pig. This paper discusses the characteristics, advantages, parameters and application of 2 inch flanged pig in oil and gas industry.

Features:

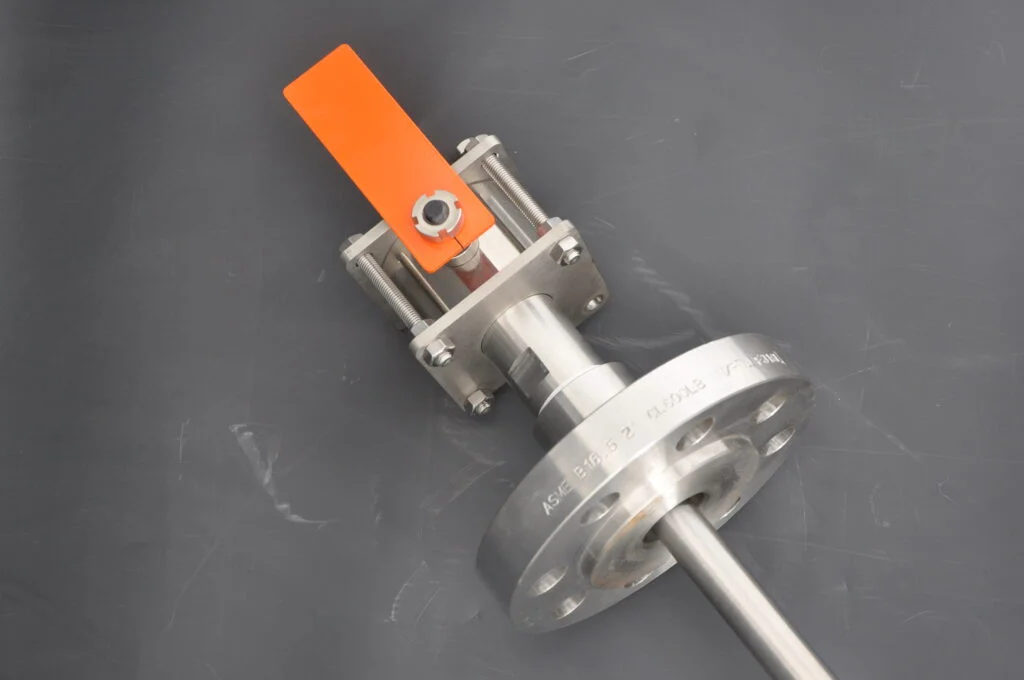

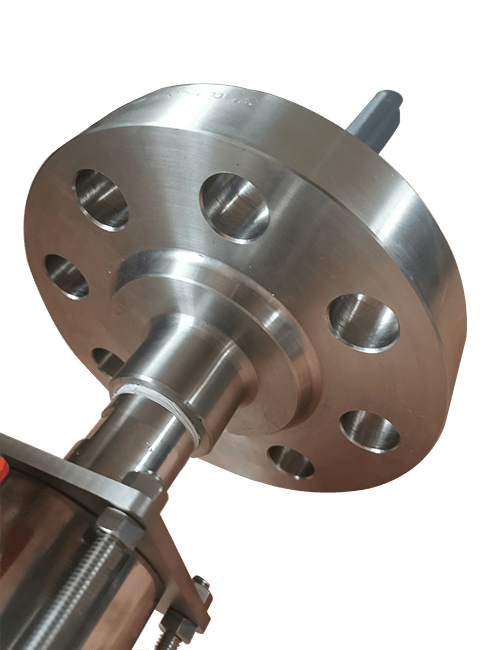

- Installing Type: These pig signallers are designed with a 2-inch flange connection, adhering to the ASME B16.5 standard (CLASS150-2500). This ensures compatibility and easy installation within the pipeline system.

- Plug Body Length: The plug body length of 200mm (or as per customer requirements) provides flexibility to accommodate different pipeline configurations and dimensions.

- Insert Depth: With an insert depth of 21mm, the pig signallers can effectively detect the passage of pigs while minimizing interference with the pipeline flow.

- Insert Depth Adjustment: These pig signallers feature an unadjustable insert depth, ensuring consistent and reliable performance during operation.

- Operating Temperature: The pig signallers are designed to withstand a wide range of temperatures, typically ranging from -20°C to 120°C, catering to various operating conditions and customer needs.

- NACE MR 0175: NACE MR 0175 compliance ensures that the pig signallers are resistant to corrosion in environments containing hydrogen sulfide (H2S) and other corrosive elements commonly found in the oil and gas industry.

- Ingress Protection: With an IP66 rating, the pig signallers offer excellent protection against dust and water ingress, ensuring durability and reliable operation even in harsh environmental conditions.

- Remove Under Pressure: These pig signallers are designed for installation while the pipeline is on-stream, allowing for easy integration without disrupting critical production activities.

- Trigger Type: The pig signallers provide both bi-directional and uni-directional trigger options, allowing flexibility in detecting pig passage regardless of the flow direction in the pipeline.

- Internal Part Material: The internal parts of the pig signallers are constructed using 316LSS, a high-quality stainless steel known for its corrosion resistance and durability.

- Flange/Body Material: The flange and body materials are made of PTFE-coated A105N, offering excellent chemical resistance and enhanced protection against corrosion.

Advantages:

Easy installation: The 2-inch flanged pig signal can be easily installed without interrupting production activities. This feature enables efficient and timely pigging, minimising downtime and maximising productivity.

Lower risk and fewer moving parts: Compared to other pig indicators, these pigs have fewer moving parts, simplifying the installation process and reducing the risk of damage during calibration. The hemispherical design eliminates common alignment problems, saving time and cost.

Bidirectional activation: The pig signal detects the pig’s passage in both directions, providing flexibility when the line is offline or the pig needs to run countercurrent. This feature ensures accurate and reliable inspection of pig under a variety of pipeline conditions.

Reliable operation: The pig signal operates reliably, regardless of the presence of wax or debris in the pipe. Its specially designed structure prevents debris from obstructing its operating mechanism, ensuring that the pig’s passage is always indicated. This reliability increases the efficiency of pipe cleaning operations.

Universal and adaptable: The 2-inch flanged pig signal is highly versatile and can be retrofitted to most installations. This adaptability can be easily integrated into existing pipeline systems, making it suitable for a wide range of applications in the oil and gas industry.

Parameters:

- Installing Type: 2” Flange (ASME B16.5 CLASS150-2500) connection ensures a secure and standardized installation.

- Plug Body Length: The pig signallers offer a plug body length of 200mm, which can be customized to meet specific customer requirements, ensuring compatibility with different pipeline configurations.

- Insert Depth (In Pipe): With an insert depth of 21mm, the pig signallers effectively detect pig passage while minimizing interference with the pipeline flow.

- Insert Depth Adjustment: The pig signallers have an unadjustable insert depth, providing consistent and reliable pig detection.

- Operating Temperature: The pig signallers can operate within a wide temperature range of -20℃ to 120℃, ensuring suitability for diverse operational environments.

- NACE MR 0175: These pig signallers comply with NACE MR 0175 standards, making them resistant to corrosion in environments with hydrogen sulfide (H2S) and other corrosive elements.

- Ingress Protection: With an IP66 rating, the pig signallers offer excellent protection against dust and water ingress, ensuring reliable performance in challenging environmental conditions.

Applications in the Oil and Gas Industry:

2-inch flanged pig signallers play a vital role in the oil and gas industry, especially in pipeline cleaning operations. Their applications include:

Pig channel detection: The main function of the pig signal is to detect the channel of the pig in the pipeline. By accurately indicating the arrival or passage of the pig, they ensure the effectiveness of the cleaning operation and help maintain optimal pipe performance.

Effective pipe maintenance: Regular cleaning of pipes is necessary to remove accumulated debris, wax, and other contaminants. Pig improves pipeline maintenance efficiency by detecting pig channels in real time, enabling timely cleaning interventions and reducing the risk of job disruptions.

Prevent flow barriers: Reliable operation of pig signals ensures timely identification of obstructions or blockages in the pipeline. By identifying these issues in time, maintenance teams can take corrective action to prevent flow disruptions and keep oil and gas shipments flowing without interruption.

Compatibility with various pipe configurations: The adaptability of the 2-inch flanged pig signaller allows it to be integrated into a variety of pipe systems. Whether it is an offshore platform, an onshore network or a power distribution system, these pigs can be customized to meet specific requirements and ensure compatibility with a variety of pipeline configurations.

Improve safety and compliance: Effective pigging helps improve safety and compliance in the oil and gas industry. By ensuring proper pipe cleaning and maintenance, these cleaners help prevent corrosion, pressure build-up and potential safety hazards, ensuring compliance with industry regulations and standards.

In summary, the 2-inch flanged pig signal is a key device for detecting pipeline pig channels in the oil and gas industry. Easy to install, reliable, adaptable and compatible with a wide range of pipe configurations, these piggies help clean and maintain pipes efficiently and improve overall operating efficiency.

Reviews

There are no reviews yet.