Description

Introduction of the Non-Intrusive Pig Signaller

Non-invasive pigging signallers are used for pigging oil, gas, water and other pipelines. The tool serves as an effective surface indicator to verify the passage of the pig through the pipeline. It has a design that is easy to install and remove, while being adaptable enough to meet a variety of pipe specifications. All the operator needs to do is securely attach the indicator to the outside of the pipe for it to function.

Concerns about mechanical through indicators being prone to fire, mechanical failure, or lack of explosion-proof performance need not apply here. We ensure the highest quality of our products to mitigate these problems. This also helps to minimize factors that can affect the accuracy of pig detection judgments, as well as false positives or missed positives caused by electronic interference.

Structure of the Non-Intrusive Pig Signaller

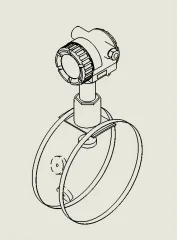

The non-invasive pig signaller consists of several key components: an explosion-proof remote transmission display module (TZS), a sensing mechanism, a detachable clamping mechanism, a connecting wire and an extension rod. The latter is usually used to bury underground pipes if needed. The LCD of the display mechanism integrates the heating function to record the passage time of the pig, keeping up to 100 records and transmitting this information remotely. With D II BT6 explosion-proof certification, protection level IP65.

The core part of the magnetic explosion-proof through indicator is the key part of the sensing mechanism, which is composed of anisotropic reluctance circuit, balanced amplifier circuit, low-pass filter circuit, trigger circuit and CPU. The supplementary components include a remote switching circuit, a display circuit and a reset circuit. These components work together to ensure the efficient and safe operation of the non-invasive pig signaler.

The Principle of Magnetic Particle Inspection

The principle of magnetic particle testing is to surround the magnetization of a workpiece made of a magnetic conductive metal material until it reaches a saturated state. If the material is uniform and free of defects, it will show a uniform distribution of magnetic field lines within it.

However, if there are defects such as cracks, slag inclusion or pores on or near the surface of the workpiece, these defects will hinder the flow of magnetic field lines, resulting in so-called magnetic leakage. This phenomenon creates a local magnetic field with North (N) and South (S) poles on the surface on either side of the defect.

When the surface of the workpiece is stained with magnetic powder or suspended magnetic powder, the leakage magnetic field will attract and retain magnetic powder. This results in a concentration of magnetic particles that effectively outline the defect, providing a clear visual representation of the location and shape of the defect.

In short, magnetic particle detection is the use of magnetic and small magnetic particles to find defects in conductive materials. This is a bit like a magnifying glass that can “see” potential problems inside a material, making it a valuable tool for ensuring the integrity of the material.

Frequently Asked Questions about Pig Signaller

Question 1: What are the main functions of non-invasive pig signaller?

A: The main function of a non-invasive pig signal is to detect and signal the passage of the pig (cleaning, inspection or separation equipment) through the pipeline without invading the pipeline itself. It helps to effectively and safely monitor and manage pipeline operations.

Question 2: How does a non-invasive pig signaller work?

A: The non-invasive pig signaller senses the pig’s channel through an anisotropic reluctance circuit, a balanced amplification circuit, a low-pass filter circuit, a trigger circuit, and a CPU. When the pig passes by, the device records the event and can transmit that information remotely for monitoring.

Question 3: Is the non-invasive pig signaller easy to install and operate?

A: Yes, non-invasive pig signals are designed to be user-friendly. It can be easily installed on the outside of the pipe and provides a clear, reliable signal for easy monitoring of the pig channel. The device is also equipped with a remote transmission display mechanism for easy operation.

Reviews

There are no reviews yet.