Description

Introduction

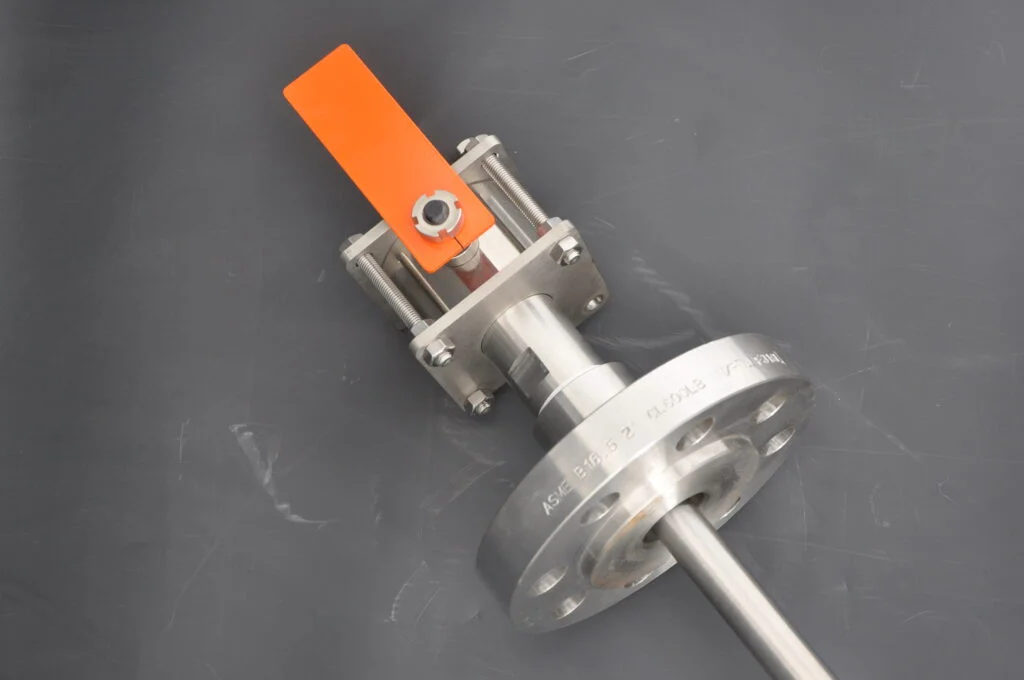

The invasive, bidirectional trigger Pig Signal Detector is used to monitor the passage of pigs. It can be equipped with a variety of indicators such as A, B, C, and D. When the pig passes through, the bidirectional triggers that are inserted into the pipeline activate their respective indicators:

A: Magnetic lock type pop-up flag indicator;

B: The indicator flag transitions from a horizontal state to a vertical state;

C: The indicator flag transitions from a horizontal state to a vertical state, and the SPDT or DPDT electrical switch activates and remains so;

D: The digital timer begins counting, storing the actual time when triggered, and the SPDT or DPDT electrical switch activates and remains until the factory-set countdown time, at which point the display returns to the standby state.

Media Compatibility:

The SN2-TQZ-AJ seal material is suitable for media such as compressed air, cold water, seawater, petroleum, natural gas, and fatty hydrocarbon oils.

The seal material is not suitable for media such as strong oxidizing agents, chlorinated hydrocarbons, aromatic hydrocarbons, basic hydrocarbons, ketones, and esters.

Pig Signal Detector Features

- A and B are intrinsically safe (not electrical, hence not “intrinsically safe explosion-proof electrical equipment”)

This Pig Signal Detector does not have electrical components, and there is no friction or collision between metals. - Adapts to a wide range of pipe wall thicknesses

The penetration depth of the striker on this Pig Signal Detector is designed to be adjustable, with an adjustment range of 0~10mm, and 1mm/step (half-turn).

Working Principle

Take SN2-TQZ-AJ-A as an example. The end of the movement installed on the base has a bidirectionally triggered striker that extends into the pipeline close to the wall. The striker is toggled when the pig passes through, pulling the linkage to pop up the flag indicator cap. After the flag indicator cap pops up, it remains in the popped-up state until manually reset, signifying that the pig has passed through.

After the pig passes, the striker will automatically reset. At this point, forcefully pressing down on the flag indicator cap will reset it, entering standby mode. If the flag indicator cap cannot be reset after being pressed down, it indicates that the pig is at this location, and the striker has not reset.

Main Technical Indicators

- Working pressure: 0-5MPa and 0-16MPa (or designed according to user requirements);

- Operating environment temperature: -20~120°C; (composite value, may vary for specific media)

- Base material: Q235A or 20# (standard configuration)

Installation and Inspection

Firstly, determine the protrusion length of the striker.

Rotate the movement according to the pipe wall thickness to adjust the protrusion length of the striker so that when it is installed, the spatial position of the striker’s rotation axis is 0~3mm above the inner wall of the pipe. Note down the relative position b of the movement and the base (the distance from the mouth of the movement display base to the mouth of the base).

Secondly, complete the welding and installation process of the Pig Signal Detector in four steps.

a) Insert the flow-through indicator, which has the protrusion length adjusted, into the hole in the pipe. Rotate the movement so that the straight line formed by the movement’s flat mouth is parallel to the direction of the pipe. Weld a point at the joint to position it. When the step on the base can’t complete the insertion depth positioning itself, manual positioning is needed during welding.

b) Unscrew the movement from the base and put it in a clean packaging box.

c) According to the welding requirements (see VII, Welding Requirements), firmly weld the base to the pipe.

d) After the base cools down, apply lubricating oil to the seal surfaces of the movement and the base, then reinstall the movement onto the base. The value of b should basically comply with the noted dimensions, and the straight line formed by the flat mouth should be parallel to the pipe direction. Then, tighten the lock nut to ensure external sealing and prevent the movement from rotating.

Check the installation accuracy by measuring the external dimensions (72 bases, 123 insert as an example):

- The straight line formed by the insert’s flat mouth is parallel to the direction of the pipe.

- When the hole size is φ51±1mm (i.e., wall thickness 415mm), b=51mm when the pipe wall thickness is 45mm, for every 1mm increase in pipe wall thickness based on 5mm, b decreases by 1mm (for example: when the pipe wall thickness is 8mm, b should be between 48±1mm).

- When the hole size is φ56±1mm (i.e., wall thickness 16~25mm), b=51mm when the pipe wall thickness is 16mm, for every 1mm increase in pipe wall thickness based on 16mm, b decreases by 1mm.

Maintenance

The non-metallic sealing ring between the base and the movement of the SN2-TQZ-AJ Welded Base Flag Indicating Pig Signal Detector is used to seal the pipe media. After installation, its sealing surface will automatically match the sealing surface dimensions of the movement and the base. When it is necessary to remove the movement for off-site maintenance or replacement, a small pry bar such as a flat-blade screwdriver should be used. The flat blade should be inserted into the groove in the upper part of the sealing ring, and the non-metallic sealing ring should be carefully removed and labeled (including the machine position and time) for storage. It can be reused when the original matching movement is returned. When installing a new movement on the original base, a new sealing ring should be used.

Once a new sealing ring has been used, it can be reused only when it remains with the movement that used it. In other words, a used sealing ring can be installed on other compatible bases along with the movement that is used.

If there is a leak at the sealing ring, first check whether the lock nut is tightened. If it is tightened, it is very likely that the sealing surface was not clean during installation, causing the seal to be not tight. In this case, the pipe needs to be shut down and depressurized for reinstallation. During reinstallation, it should be determined whether a new sealing ring is needed based on the situation.

If the Pig Signal Detector has been contaminated with viscous material, the stainless steel cylinder should be disassembled first, then the components of the stainless steel cylinder should be disassembled for cleaning.

Reviews

There are no reviews yet.