Description

1. Introduction

The Non-intrusive Pig Passage Detector has revolutionized the field of pipeline maintenance and inspection. This innovative technology, designed to detect, track, and monitor pipeline inspection gadgets known as ‘pigs’, has brought about significant change in the industry. Unlike traditional methods, the Non-intrusive Pig Passage Detector, as the name suggests, performs these tasks without interfering with the integrity of the pipeline, making it a safer and more efficient alternative.

Understanding the importance and relevance of this technology is crucial in today’s era where pipeline infrastructure forms the backbone of many industries, from oil and gas to water treatment. The introduction of non-intrusive technology has not only enhanced the efficiency of pipeline inspections but also significantly reduced the risks associated with pipeline maintenance. As such, the Non-intrusive Pig Passage Detector has become an indispensable tool in safeguarding the smooth operation of these vital conduits, reinforcing its relevance in our modern industrial landscape.

2. What is a Non-intrusive Pig Passage Detector?

2. What is a Non-intrusive Pig Passage Detector?

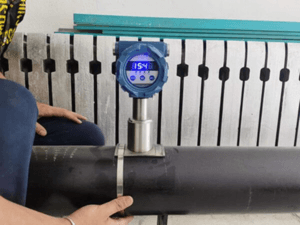

A Non-intrusive Pig Passage Detector is a sophisticated device used in the pipeline industry to detect, track, and monitor the movement of ‘pigs’ within pipelines. ‘Pigs’ are specialized devices or tools that are inserted and travel within the pipeline for various purposes such as cleaning, inspection, or separation of different products within the pipeline. The Non-intrusive Pig Passage Detector uses advanced technology, often magnetic or ultrasonic, to sense the pig’s passage without any need for physical intrusion into the pipeline, hence the term ‘non-intrusive’.

This non-intrusive technology marks a significant departure from traditional pig passage detectors, which typically require some form of physical intrusion into the pipeline. Traditional methods often involve mechanical or intrusive electronic detectors that require fittings or alterations to the pipeline, which can present risks such as leaks or disruptions to the pipeline operation. However, the Non-intrusive Pig Passage Detector eliminates these risks by allowing for detection from outside the pipeline. This not only enhances safety but also reduces downtime, as there is no need to halt operations for detector installation or maintenance.

Indicator code | B | C | D |

Type | Intrusive China Passage Pig Passage Detector | ||

Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Installing type | 2″Welded base, nipple joint. Design pressure up to 3000Psi | ||

Trigger type | Uni-directional | ||

Insert depth (In pipe) | 13 mm | ||

Plug body length | settled | ||

Insert depth adjustment | 20 mm | ||

Operating temperature | -20~+120℃/Meet customer requirements | ||

NACE MR – 01- 75 | Yes | ||

Ingress protection | IP65/IP66 | ||

Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | |

Include isolation valve | NO | ||

With bypass valve | NO | ||

With bleed valve | NO | ||

Remove under pressure | Yes | ||

Retriever | Special retriever | ||

3. How Does a Non-Intrusive Pig Passage Detector Work?

A Non-intrusive Pig Passage Detector operates on the principle of detecting changes in the physical properties of the pipeline when a pig passes through. The specific technology used can vary from one detector to another, but commonly used methods are magnetic field detection, ultrasonic waves, or radio frequency identification (RFID).

In the case of magnetic field detection, the detector is equipped with sensors that can sense changes in the pipeline’s magnetic field caused by the passage of the pig. These sensors are usually mounted externally on the pipeline and can detect the pig’s movement without any need for physical intrusion into the pipeline.

For ultrasonic wave-based detectors, the principle is similar. Ultrasonic sensors emit sound waves which, when they bounce back from the pig as it passes through the pipeline, can be detected and interpreted by the device. This allows the detector to pinpoint the exact location of the pig within the pipeline without having to penetrate the pipeline physically.

RFID-based detectors, on the other hand, work by attaching RFID tags to the pigs and using an external reader to detect their passage. This method has the advantage of allowing for more detailed tracking and data collection.

The non-intrusive nature of these detectors lies in their ability to detect and track pigs externally, without the need for any alterations to the pipeline. This brings significant advantages in terms of safety and efficiency, as there is no risk of leaks or operational disruptions associated with pipeline modifications.

4. Benefits of Using a Non-intrusive Pig Passage Detector

The use of Non-intrusive Pig Passage Detectors offers numerous benefits over traditional intrusive methods, the first and foremost being enhanced safety. Traditional detectors require physical modifications to the pipeline, potentially leading to leaks or other operational disruptions. In contrast, non-intrusive detectors are installed externally, eliminating these risks.

Efficiency is another significant advantage. Non-intrusive detectors can be installed and maintained without interrupting pipeline operations, minimizing downtime. This is a stark contrast to intrusive methods, which often require operations to be halted during installation and maintenance, impacting productivity.

Furthermore, non-intrusive detectors often provide more accurate and reliable data. Technologies like magnetic sensing, ultrasonic waves, or RFID allow for precise tracking and monitoring of pigs, ensuring efficient and effective pipeline inspections and cleanings.

To illustrate, consider a real-world example in the oil and gas industry. Companies often use pipelines to transport crude oil over long distances. Any disruption in the pipeline due to a blockage or maintenance issue can result in significant operational and financial losses. Using a Non-intrusive Pig Passage Detector allows these companies to monitor pig movement closely, enabling timely detection and resolution of any issues. This not only ensures the smooth running of operations but also saves substantial costs that might otherwise be incurred due to operational downtime.

Moreover, in industries where the transported material is hazardous or under high pressure, the use of non-intrusive detectors significantly reduces the risk of accidents or environmental damage. Hence, the Non-intrusive Pig Passage Detector is not just an operational advantage, but a major contributor to industrial safety and environmental protection.

5. Applications of Non-intrusive Pig Passage Detector

Applications of Non-intrusive Pig Passage Detector

Non-intrusive Pig Passage Detectors find applications in a wide range of industries, anywhere pipelines are used for the transportation of materials. The oil and gas industry is a prime example, where these detectors are used extensively to monitor the movement of pigs during pipeline inspections and cleanings. In this context, Non-intrusive Pig Passage Detectors play a crucial role in maintaining the operational efficiency of long-distance oil and gas pipelines and ensuring the timely detection and resolution of any blockages or maintenance issues.

Another industry where these detectors are widely used is the water treatment sector. Here, pipelines are often used to transport water or wastewater over long distances. Non-intrusive Pig Passage Detectors enable these industries to conduct regular inspections and cleanings without disrupting their operations. The detectors help identify any issues early, thereby preventing potential failures that could lead to significant operational downtime or environmental damage.

Improving Efficiency and Safety

The use of a Non-intrusive Pig Passage Detector greatly improves both efficiency and safety in these applications. From an efficiency standpoint, being able to conduct inspections and maintenance without interrupting operations minimizes downtime and enhances productivity. This is particularly crucial in industries like oil and gas, where any disruption can result in significant financial loss.

From a safety perspective, the non-intrusive nature of these detectors eliminates the risks associated with physical modifications to the pipeline, such as leaks or operational disruptions. This is especially important in industries where the transported material is hazardous or under high pressure. By enabling external monitoring and detection, the Non-intrusive Pig Passage Detector significantly reduces the risk of accidents, contributing substantially to industrial safety and environmental protection.

6. Conclusion

In conclusion, the Non-intrusive Pig Passage Detector has emerged as a game-changing technology in the field of pipeline maintenance and inspection. Its ability to detect, track, and monitor the movement of pigs without physically intruding on the pipeline has significantly enhanced both the safety and efficiency of pipeline operations. With applications spanning a wide range of industries, from oil and gas to water treatment, these detectors have proven invaluable in reducing operational downtime and preventing potential disasters. As pipelines continue to form the backbone of our modern industrial infrastructure, the importance of Non-intrusive Pig Passage Detectors cannot be overstated. They represent a significant step forward in pipeline management technology, embodying the continual efforts towards safer, more efficient industrial operations. In a world increasingly focused on efficiency and safety, the role of such non-intrusive technologies is set to become ever more critical.

7. Why Choose Us

Selecting our company grants you access to a dedicated team that truly values your business. Our team comprises professionals who strive to continuously learn and adapt in this ever-evolving industry. We offer solutions such as the Non-intrusive Pig Passage Detector, ensuring we provide the most relevant and up-to-date technology to meet your needs. Our commitment to quality and customer satisfaction is reflected in our diligent work and the positive feedback we receive from our clients.

Our team is the heart of our company. Each member brings a unique set of skills and perspectives to the table, contributing to a collaborative and dynamic work environment. We emphasize open communication and mutual respect, creating a supportive atmosphere that nurtures innovation and problem-solving. Our team’s primary focus is to meet your needs and expectations while being prepared to address any future challenges that may arise. Your success is our success, and we are committed to making that a reality.

2. What is a Non-intrusive Pig Passage Detector?

2. What is a Non-intrusive Pig Passage Detector?

Reviews

There are no reviews yet.