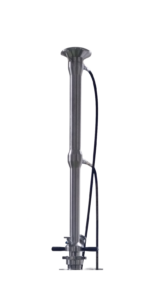

Description

The Hydrumatic Retriever Tool is a specialized device engineered for the extraction of corrosion coupons, probes, and other monitoring instruments from pressurized pipelines and vessels. This tool allows operators to safely retrieve data without the need for a complete system shutdown, thereby maintaining continuous operation and minimizing downtime. Its hydraulic mechanism is designed for ease of use and reliability, ensuring that maintenance personnel can perform necessary inspections and replacements efficiently and with minimal risk. The Hydrumatic Retriever Tool is an invaluable asset in the field of industrial maintenance, contributing to the ongoing efforts to monitor system integrity and prevent corrosion-related failures.

Introduction

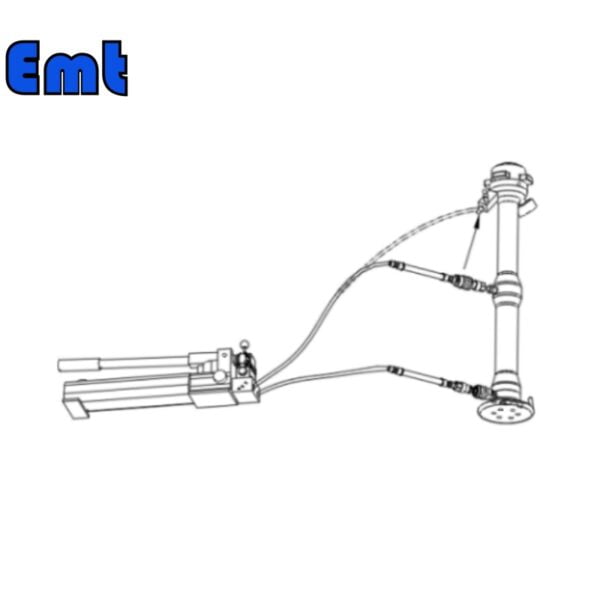

The content of this article provides only technical information on the operation of the EMT double-acting hydraulic take-and-place tool and is not intended to provide buyers or users with information on the correct take-and-place of probes in piping systems under working pressure. The probe removal procedure in this article is for reference only.

The tool owner or operator must develop specific retrieval procedures for each application. At a minimum, these procedures must consider the safety of the tool operator and the technical impact on the piping system. In addition, the approved probe removal procedure must be compared with the example used in this hydraulic retrieval tool operating manual to ensure that there is no conflict between the example and the approved probe take-and-place procedure.

Only use tools made of materials that do not spark when used, such as tools with a plastic or brass surface!

Use approved personal safety protective gear such as glasses, gloves, helmets, shoes, etc., when operating hydraulic lifting tools!

Operator qualification

Operating a hydraulic lift tool on a running pressure system can be very dangerous. This must be done by appropriately trained personnel following procedures approved by the operating system owner.

However, it is very important that only those who fully understand the working principle of the hydraulic lifting tool and have received operational training can operate the hydraulic lifting tool. Therefore, simply reading this manual is not enough. Before working on any “pressurized” piping system, the operator should receive adequate training from a qualified trainer.

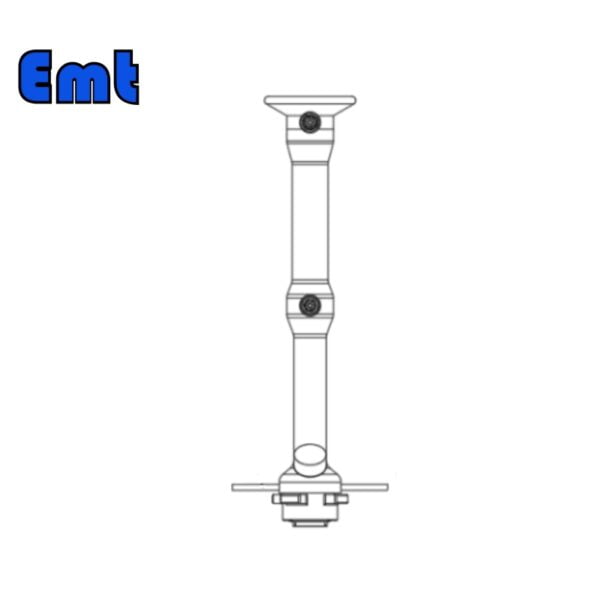

The operator should also be familiar with the different parts of the object being serviced or placed, such as hollow and solid inserts, locking pins, protective covers, and the different types of seals used on these parts.

Preparatory work

Take and place operation precautions

I set up warning areas, safety signs, and non-operators before the start of the operation all leaving the warning range.

A portable gas detector (hydrogen sulfide or flammability) must be worn before the operation to monitor oil and gas leakage.

Iii In the whole process of operation places with high sulfur gas must wear air breathing apparatus, one person to operate, and one person to monitor.

If the ground in the operation area is wet, anti-slip measures should be set to ensure the safety of the operator.

The drainage hydraulic hose should be placed in the empty downwind. Check the surrounding environment before discharge, inform the rest of the personnel to stay away, slowly open the vent valve, slow pressure relief at a slow speed to prevent the hydraulic hose from bouncing and wounding people, and use a bucket to collect the liquid and gas discharged during discharge.

When operating, you must wear protective equipment and be supervised;

Ⅶ When removing the limit bolt, operate on the side of the limit bolt to prevent the limit bolt from ejecting and hurting people.

Ⅷ The operator observes the pipeline pressure at any time and timely adjusts the operating pressure of the hydraulic take-and-place tool.

Wear clean protective gloves when installing a new hanger.

Attentions When Using the Hydrumatic Retriever Tool

If the Hydrumatic Retriever Tool construction is to be carried out at a specific location, it must be clear with the operator responsible for the area/piping system before construction starts.

The use of hydraulic take-and-place tools requires the expulsion of pressurized liquid/gas from the piping system. If the pipe system contains hydrocarbons, the discharged liquid/gas may trigger the gas detector, so such operations must be explained to the operator responsible for the area/pipe system before work begins. The following safety precautions should be taken:

– The operator/control room must be informed of the start and stop times of work at each location.

– Inform the operator/control room before oil/gas venting to avoid any gas detector alarm during the oil/gas venting process and to stop nearby heat and spark-generating work.

.jpg)

Reviews

There are no reviews yet.