Description

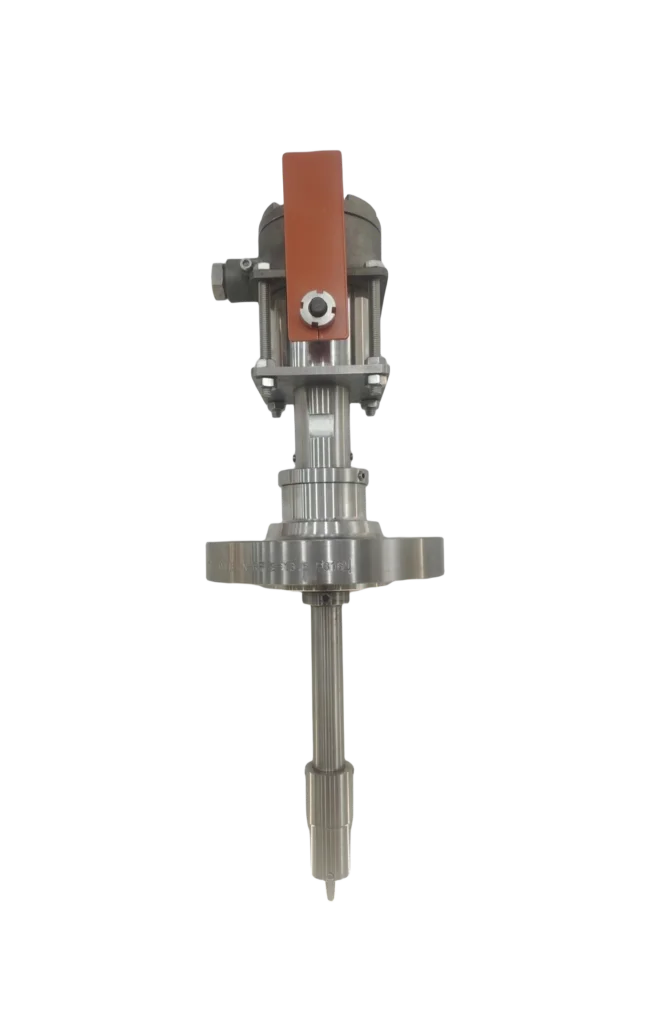

EMT provides a range of scraper passage indicators, also known as Intrusive Pig Signallers. These devices precisely track, signal, and log the movement of pipeline pigs at crucial junctures in onshore, offshore, and subsea pipelines. All of our intrusive signallers meet NACE MR-01-75 standards and come standard with a 3.1 Certification. For remote tracking, we can equip the signallers with electrical switches, either proximity or limit, to indicate the passage of pipeline pigs.

Brand Name | EMT |

Product Name | Intrusive Pig Signaller |

Flange Material | 304SS、316SS、DSS F51、DSS F53、 DSS F55、Carbon Steel A105N、Inconel 625 |

Flange Presure | class150#、class300#、class600#、class900#、class1500#、class2500# |

Operating Temperater | from -20°C to +120°C |

Basic Feature or Parameter | ||||

| B | C | D | ||

| Type | Intrusive Type | |||

| Indicator Type | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals | |

| Installing type | Flange. As per ASME B16.5 (CLASS150~2500)/ Welding connection | |||

| Plug body length correspond to total stand-off | 200mm/Meet the actual requirements | |||

| Insert depth adjustment | 20mm | |||

| Operating temperature | -20~120℃/Meet customer needs | |||

| NACE MR 0175 | Yes | |||

| Ingress protection | IP66 | |||

| Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | ||

| Remove under pressure | NO | |||

Main Technical Aspects

The main technical aspects of our product are as follows:

- Working Pressure: Options include 4.0MPa, 6.4MPa, and 10MPa.

- Power Supply: The device operates on 4 A 1.5V alkaline batteries.

- Battery Life: The batteries can last for at least 10 working hours.

- Record and Display Modes:

After a pig passes the trigger, the instrument will increase the count by 1. If inactive for 2 hours, the instrument will automatically shut down. The top row displays the count and total time, while the bottom row shows the current time.

You can press the side button at any time to display the battery test result after a brief delay. The device will automatically shut down after providing bilingual prompts. If the battery level is low, the device will shut down immediately after recording the pass count and time to save energy. - Installation: The standard configuration uses an ANSI600#RF flange connection above the pipeline.

- Installation Requirements: The distance between the top of the installation flange on the pipeline and the inner wall of the pipeline should be within ± 2mm of the chosen penetration length.

- Operating Temperature: The device can operate between -20℃ and 75℃.

- Clock Accuracy: The clock error should be no more than 2 minutes per year.

- Remote Transmission Output Specifications:

- Interface: 1/2NPT. Note: This refers to a 1/2 inch tapered pipe thread with 14 threads, following the American National Pipe Thread standard.

- Switch Type: Solid State Relay SPDT/DPDT or a mechanical relay.

- Switching Capacity: 2A/24VDC.

EMT Intrusive Pig Signallers play a crucial role in confirming the movement of pipeline pigs throughout a pipeline. They are typically installed at both the pig launching and receiving stations, as well as at important locations along the pipeline. We offer four distinct types of indicators. Type A is the Popper, Type B is the Manual reset flag, Type C is a combination of the Manual reset flag with an electrical switch output, and Type D combines a digital display with an electrical switch output. Each type serves a unique role to ensure efficient and effective pipeline pig tracking.

| Optional Feature | ||||

| ● Standard configuration ○ Optional configuration — None | ||||

| Trigger type (B-Bi-directional/U-Uni-directional*) | ●/○ | |||

| Internal part material (316L SS/DSS/INCONEL) | ●/○/○ | |||

| Flange/Body material (PTFE Coated A105N/304SS/316LSS/DSS/INCONEL /As per MR) | ●/○/○/○/○/○ | |||

| The position of Internal liquid surface (High_Need to heat/Low_With no need for heating) [Only uni-directional pig signallers] | ●/○ | |||

| Junction box material (Aluminium alloy/316SS) | —/— | ○/● | ●/— | |

| Switch type (DPDT/2*SPDT) | —/— | ○/● | ○/● | |

| Switch rating (DC24V 3A/DC24V 5A) | —/— | ●/○ | ●/— | |

| Electrical connection size (M20×1.5(F)/1/2″NPT(F)) | —/— | ●/○ | ●/— | |

| * The standard Uni-directional trigger configuration is a spherical shape. | ||||

| Relationships between trigger and insert depth (in pipe) | ||||

| Trigger type | Bi-directional | Uni-directional | ||

| Insert depth (In pipe) | 21mm | 13mm | ||

Installation Method

Pre-installation check: Before installation, ensure that the indicator’s mechanical body and display mechanism are flexible and reliable. The operator should disassemble the main body of the machine following the structure and installation diagram. The base and pipeline should then be welded separately.

Welding base:

- No-pressure installation: Clean the installation site, removing all attachments to expose the bare metal. Straighten the base (align it for welding) such that the slotting direction at the upper end of the base is parallel to the pipeline’s centerline or the mark on the upper end of the base aligns with the pipeline’s centerline. (The slotting direction or symbol on the base should be consistent with the trigger’s movement direction.) Secure the base to prevent shifting or deflection during welding.

- Installation under pressure: Refer to the operating instructions of the drilling machine. Note: When welding the base on the pipeline, the pressure (P) inside the pipeline must be limited.

Final assembly: After the main body of the machine is welded and installed, reassemble the main body of the machine in sequence according to the structure and installation diagram. Attach the display mechanism using fastening screws as per the structure and installation diagram. Adjust the direction of the display mechanism for easier observation.

Our Comprehensive Services

At EMT, we take pride in providing a diverse selection of Intrusive Pig Signallers, each designed to meet specific needs. Our products are the results of years of expertise and meticulous engineering, designed to deliver high performance reliably.

We warmly invite you to connect with us and explore how our products can be tailored to your specific requirements. Our goal is to assist you in identifying the optimal solution that not only meets your operational challenges but also fits within your budget.

To showcase the exceptional quality of our products, we extend an offer to potential clients to request sample units. This allows you to experience the superior construction and functionality of our units, providing reassurance before you make a purchase decision.

Our Dedication to Customer Service

We are firm believers that outstanding customer service is the key to forging successful business partnerships. Our team of committed professionals is always ready to offer immediate responses and address any concerns or questions you may have. Our objective is to provide prompt, clear, and useful answers to your queries.

Furthermore, we are committed to ensuring swift delivery times. We comprehend the importance of timely operations in your business, and our goal is to make sure you receive your orders without delay. To cater to your needs at any hour of the day, our online support is operational 24/7, ready to assist you whenever required.

Packaging and Delivery

Our products are thoughtfully packaged in cases, offering several advantages:

- These are lightweight and aesthetically pleasing, with clean lines. They provide insulation and boast high strength, ensuring that our products reach you in perfect condition without susceptibility to deformation.

- These cases eliminate the need for fumigation, streamlining the shipping process and making it more efficient.

Our commitment extends beyond providing top-quality chemical injection quills. We aim to deliver these promptly and efficiently, always prioritizing your satisfaction. We believe in building strong relationships with our clients, and your satisfaction is our utmost priority. Let us be your trusted partner in your journey towards operational excellence.

Reviews

There are no reviews yet.