Description

Introduction

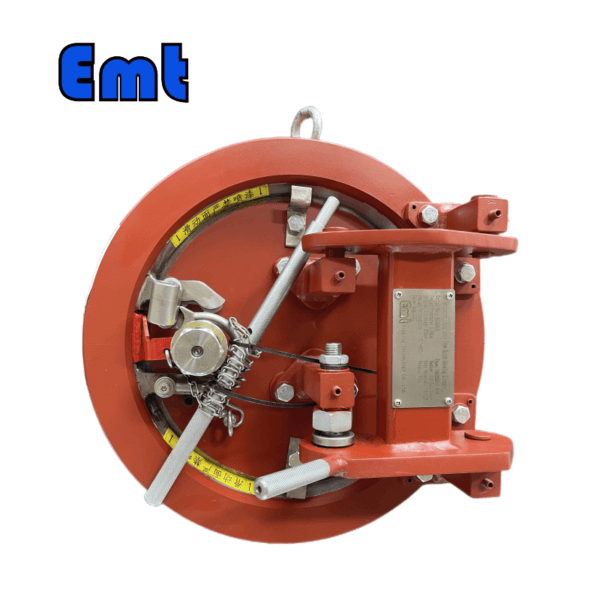

The EMT Quick Closures allow users to quickly and easily access (open or close) any pressure vessel, whether its orientation is horizontal or vertical. They’re designed for safe and fast opening and closing, outperforming other quick-opening closures. Regardless of the unit size, they can be opened or closed in less than a minute without the need for special tools. Computer-aided technologies significantly improved the Quick Closures design. The primary pressure-loaded elements were designed to be lightweight while still adhering to the main pressure vessel code standards. This was achieved using finite element analysis and strain gauge proof testing.

The operation procedure and precautions of the Quick Closures

Opening Quick Closures requires trained personnel who must first read the signs on the device. To check for pressure in the cylinder before opening, unscrew the vent bolt by hand. Then, fully release the pressure. The operator should then unscrew the hollow screw, keeping in mind that a small chain connects the safety plug and hinge. The operation continues with the gradual unscrewing of the screw until the nut bracket contacts the tail bolt, after which the slider handle is retrieved and the flange part of the blind plate is opened.

Closing Quick Closures involves cleaning and lightly oiling the sealing ring, as well as cleaning and greasing the gasket’s surface. Bolts should also be lubricated with grease before the blind flange is closed. The operator should gradually tighten the stud bolts, stopping when the two nut brackets touch and avoiding the use of a wrench. Vent bolts and bolt holes should be coated with oil before the safety block and handle are restored. It’s essential to use appropriate tools during closing to prevent damage to the safety chain system.

The Essential Role of Quick Closures in Industrial Operations

Quick Closures are essentially mechanical devices used in pressure pipelines and vessels, notably within the natural gas sector. Comprising various components, QOCs safely seal the circular openings of these systems, catering to frequent operational needs. Our company designs QOCs following the ASME VIII Div. 1 standard, utilizing advanced stress analysis and robust materials for optimal performance under various conditions. Compliant with industry standards like GB150 and SY/T0556-2018, our QOCs are primarily used in petroleum and natural gas pipelines, underscoring their vital role in industrial operations.

Types of Quick Closures

Quick Closures come in various types, each with a unique design and mechanism to cater to different industrial needs. Here, we will delve into three of the most common types: bayonet type, clamp type, and lock ring type.

Bayonet Type Quick Closures

The Bayonet Type is one of the oldest and most traditional forms of quick closures. It comprises a flange with evenly spaced radial teeth and a corresponding cover with counter teeth.

Key Features: The cover is installed using a hinge to turn around an axis in the plane of the piping. The movement of the cover is carried out by a toothed drive mechanism.- The cover is turned around the hinge against a stop, and the teeth on the cover are brought into grooves between the teeth on the flange. Benefits: This type of closure can withstand low to moderate pressures, making it suitable for less demanding applications. Despite being metal-consuming, it’s time-tested and reliable for specific uses. Limitations: Bayonet-type closures require high closing, opening, and tightening forces, especially for larger diameters. This could lead to increased wear and tear on the sealing element.- The closure is difficult to repair without replacing the main components.

Clamp Type Quick Closures

(Yoke Type)Clamp Type, also known as Yoke Type Quick Closures, are popular for applications requiring frequent access or where blind flanges are too cumbersome and time-consuming.

Key Features:- The design includes a yoke mechanism that can be equipped with operating aids to simplify operation and speed up opening and closing. Devices such as breakover wrenches and chain and sprocket drives can be added. Benefits: This type of closure is designed to be user-friendly, minimizing the time and effort required to access the equipment.- With an extensive size range and pressure range, Yoke Type Closures can be customized for various applications.

Lock Ring Type: Quick Closures

Lock Ring Type Quick Closures, also known as Threaded Quick Opening Closures or Sector Type Closures, consist of two forged pieces—a male (threaded) and a female piece.

Key Features: The male piece is welded to the vessel, while the female piece is used to secure the closure. The opening and closing mechanisms are performed by screwing the female piece into the male piece. Benefits: This type of closure is straightforward to operate and provides a secure seal, making it ideal for applications requiring high-pressure resistance.- The Lock Ring Type Closures can be manufactured in a wide range of sizes and pressure ratings to fit various industrial needs. Each type of Quick Closure has its own unique features and benefits, and the choice between them would primarily depend on the specific requirements of the industrial process, including the frequency of access, pressure, temperature conditions, and ease of operation.

Conclusion

EMT Quick Closures revolutionize the way we access pressure vessels, promoting safety, efficiency, and versatility in various industrial contexts. Their application spans both horizontally and vertically oriented vessels, and their thoughtful design negates the need for special tools, simplifying operations. The key to their success lies in the blend of cutting-edge computer-aided technologies, finite element analysis, and strain gauge proof testing, ensuring they remain lightweight yet compliant with pressure vessel code standards.

The operational procedures, both for opening and closing these Quick Closures, emphasize the importance of trained personnel, cautious handling, and proper maintenance. The steps involved ensure the safety and longevity of the Quick Closures, ensuring the prevention of any possible damage to the safety chain system.

With a range of Quick Closure types available, including Bayonet, Clamp (or Yoke), and Lock Ring types, EMT caters to a wide variety of industrial needs. Each type comes with its own unique design features, advantages, and considerations. This diversity of options allows for customization, ensuring that there’s a Quick Closure solution for virtually any requirement, whether it’s frequent access, high-pressure resistance, or application in specific industrial processes. In essence, EMT Quick Closures stands as an embodiment of technological advancement in the realm of pressure vessel management, providing an effective and efficient bridge between safety, accessibility, and industry demands.

Reviews

There are no reviews yet.