Description

I. Introduction

Quick Opening Closures (QOCs) are specially designed pressure-containing components that offer swift and efficient access to the interior of a piping system. These devices are an integral part of many industrial pipelines and pressure vessels, designed to facilitate rapid opening and closing operations, thereby saving time and enhancing operational productivity.

These closures are designed with safety and ease of operation in mind. They can be opened or closed in a matter of minutes without the need for special tools, which is a significant improvement over traditional bolted flange connections that can take much longer to open or close. This quick actuation feature makes them particularly beneficial in systems that require frequent internal access, such as pig launchers and receivers.

QOCs are typically installed on pig launchers and receivers, pressure vessels like filter units, and blowdowns on vertical vent stacks. They are designed in adherence to specific pipeline design codes, such as ASME B31.4 for liquid pipelines or ASME B31.8 for gas pipelines. When installed on pressure vessels, they are usually designed in accordance with ASME Section VIII, Division 1.

The design and structure of QOCs vary depending on their application and the nominal diameter of the pipeline. Some common types include the bayonet type for pipelines between DN100 to DN350 and the lock-ring type for pipelines between DN400 to DN1200.

II. Choosing the Right Type of QOC

Selecting the right Quick Opening Closure (QOC) for a specific application is crucial for the efficient and safe operation of pipelines and pressure vessels. The appropriate choice of QOC can lead to enhanced productivity, lower maintenance efforts, and improved safety measures.

Importance of Selecting the Right QOC

The selection of the correct QOC type provides benefits such as easier access to the interior of a pipeline system, fewer operational disruptions, and a reduction in the time taken for maintenance tasks. Furthermore, the right QOC can help prevent potential safety hazards, such as pressure build-up or accidental opening, ensuring a safer working environment.

Criteria for Selection Based on Pipeline Nominal Diameter (DN)

The choice of QOC often depends on the nominal diameter (DN) of the pipeline or pressure vessel it is intended for. The nominal diameter is a standard numeric designation of the pipe size, which plays a significant role in determining the type of closure that can be used effectively.

- Bayonet-Type Quick-Opening Closure for DN100 to DN350 PipelinesFor pipelines with a nominal diameter ranging from DN100 to DN350, the bayonet-type quick-opening closure is often the most suitable option. This closure type is designed with a simple and efficient opening mechanism that enables quick and easy access to the pipeline’s interior. The bayonet-type closure features a male part that fits into a female counterpart, allowing for a secure and easy-to-operate connection.

- Lock-Ring Quick-Opening Closure for DN400 to DN1200 PipelinesFor larger pipelines with a nominal diameter between DN400 and DN1200, the lock-ring quick-opening closure is commonly used. This closure type is designed with a locking ring mechanism that securely holds the door in place, providing a strong and reliable seal even under high pressure. The lock-ring closure can be quickly opened by releasing the locking ring, making it an efficient choice for larger pipeline systems.

Choosing the right QOC based on the nominal diameter and specific requirements of the pipeline system can significantly improve operational efficiency and safety. Hence, it’s crucial to understand the characteristics and advantages of different types of QOCs to make an informed decision.

III. Key Technical Indicators of QOCs

Quick Opening Closures (QOCs) are engineered to meet a variety of industry requirements. To ensure suitability and performance, they are designed according to several key technical indicators. These key technical indicators guide the design and selection of QOCs, ensuring they meet the requirements of diverse industrial applications and maintain safety and efficiency in varying operating conditions.

- Nominal Diameter (DN): QOCs are designed to cover a wide range of pipeline sizes. They can accommodate a nominal diameter up to a maximum limit of 1800mm, providing compatibility with various pipeline configurations.

- Design Pressure (PN): Built to withstand high pressure, QOCs can endure pressures of up to 40MPa. This ensures that they offer reliable performance in applications where high pressures are encountered.

- Working Medium: QOCs are designed to be compatible with a variety of working mediums. Whether the pipeline is transporting oil, gas, or water, QOCs can adapt to the medium, offering versatility across different applications.

- Design Temperature: QOCs are engineered to function optimally within a broad temperature range. They can operate flawlessly in temperatures ranging from -50℃ to +300℃, making them suitable for use in extremely cold or hot environments.

- Material: QOCs are constructed from an array of high-quality materials, including 16Mn, A350LF2, A105, SS304, SS316, F51, F55, INCONEL625, and HASTELLOY C. These materials are chosen for their durability, resistance to corrosion, and longevity, ensuring that the QOCs can withstand challenging conditions and maintain their performance over time.

- Pipe Thickness: QOCs are designed to accommodate a wide range of pipe thicknesses. They can be fitted to pipes with thicknesses ranging from 6mm to 100mm, making them suitable for a broad spectrum of pipeline configurations.

IV. Structure of Different Types of QOCs

In the world of pipelines and pressure vessels, Quick Opening Closures (QOCs) come in several types, each with its unique structure and operating mechanism. Understanding these different structures is key to selecting the right QOC for a specific application.

Bayonet Type Quick Opening Closure (Horizontal and Vertical)

The Bayonet Type Quick Opening Closure is designed with a male part (the bayonet) that fits into a female counterpart. This design enables swift opening and closing of the closure without the need for any special tools.

- Horizontal Bayonet Type: In the horizontal design, the bayonet and the corresponding female part are oriented horizontally. This allows for easy access and inspection of the pipeline or pressure vessel’s interior.

- Vertical Bayonet Type: The vertical design is similar to the horizontal one, but the bayonet and the female part are oriented vertically. This design is typically used in applications where vertical installation is required due to space constraints or other considerations.

Clamp Type Quick Opening Closure (Horizontal and Vertical)

The Clamp Type Quick Opening Closure uses a hinged clamp mechanism that can be quickly opened or closed. This design provides a secure seal and is easy to operate.

- Horizontal Clamp Type: In the horizontal design, the clamp is oriented horizontally, allowing for easy access to the interior of the pipeline or pressure vessel.

- Vertical Clamp Type: In the vertical design, the clamp is oriented vertically, making it suitable for applications requiring vertical installation.

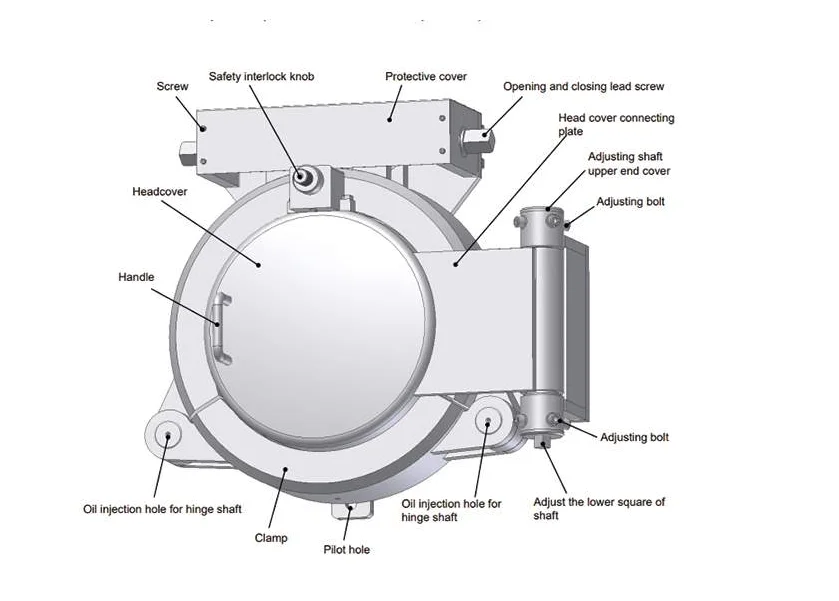

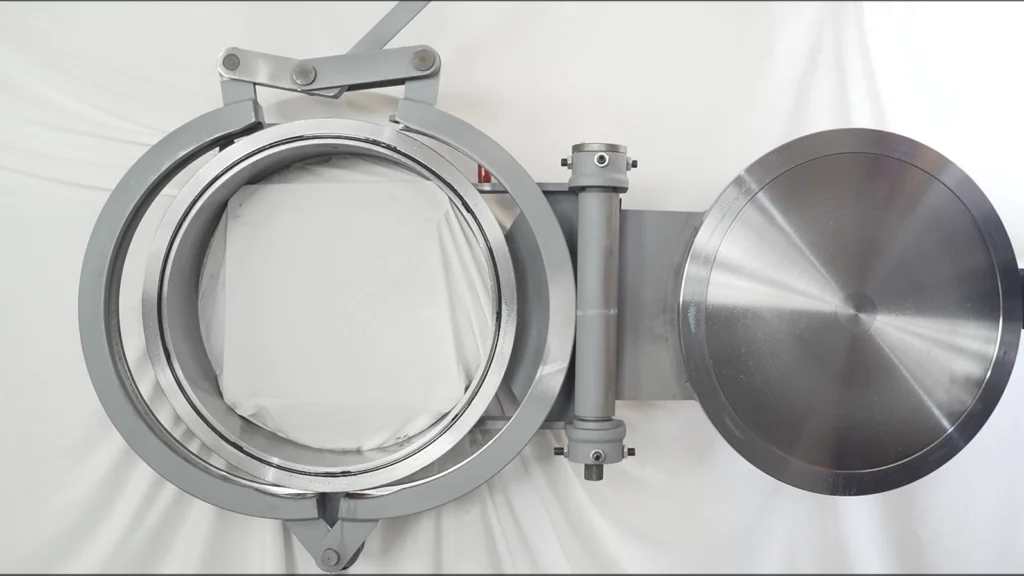

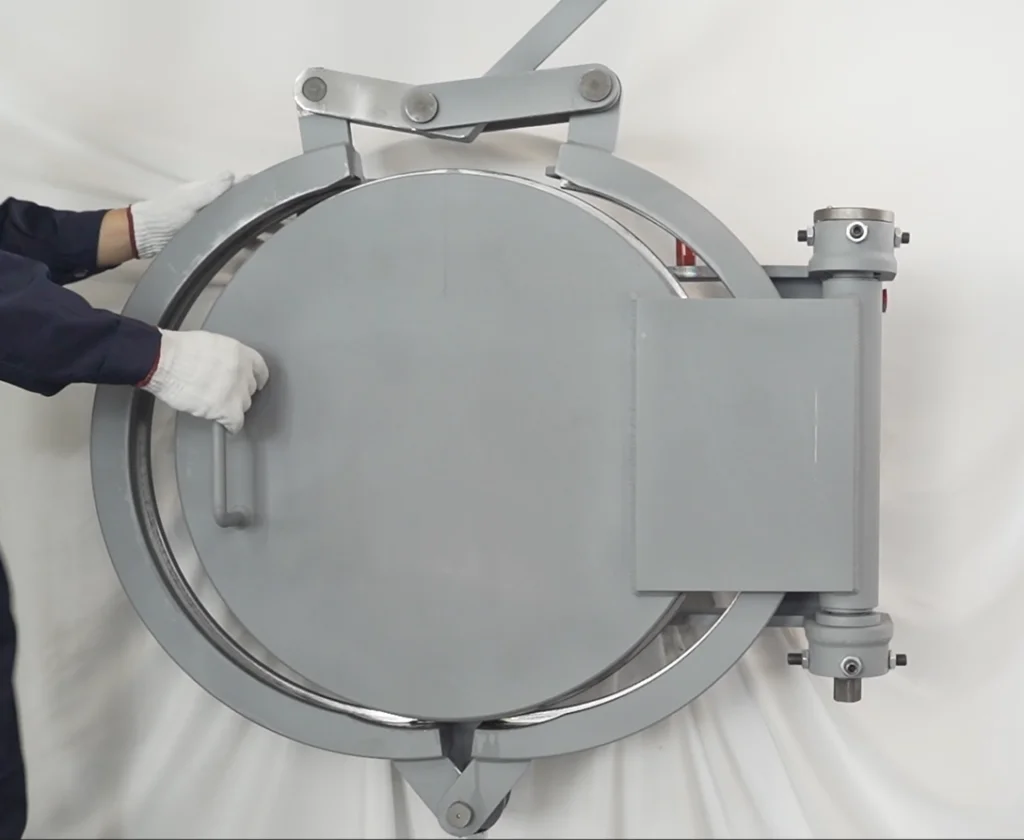

Lock Ring Quick Opening Closure (Horizontal and Vertical)

The Lock Ring Quick Opening Closure features a locking ring mechanism that securely holds the door in place. The locking ring can be quickly released to open the closure, making it an efficient choice for larger pipeline systems.

- Horizontal Lock Ring Type: The horizontal design allows for easy access to the interior of the pipeline or pressure vessel, with the locking ring mechanism oriented horizontally.

- Vertical Lock Ring Type: The vertical design features a vertically oriented locking ring mechanism. This design is used in applications where vertical installation is necessary.

V. Conclusion

Quick Opening Closures (QOCs) are essential for the effective and secure operation of pressure vessels and pipelines in a variety of industries. They are a crucial tool for maintenance, inspection, and operational chores since they provide quick access to a pipeline system’s interior.

Consideration must be given to the nominal diameter, design pressure, working medium, design temperature, material, and pipe thickness when selecting the best QOC. It is also vital to comprehend the workings of various QOC kinds, both structurally and operationally.

Each of the three types of quick-opening closures—Bayonet, Clamp, and Lock Ring—has special benefits and characteristics that are intended to meet various operational needs and pipeline layouts.

In many industrial contexts, QOCs have a substantial impact on maximizing operational effectiveness, improving safety, and requiring less maintenance. As a result, obtaining these advantages depends on choosing the appropriate QOC.

Reviews

There are no reviews yet.