Description

Introduction

The Non-Intrusive Pig Indicator serves as an efficient tool for monitoring pigging operations in oil, gas, or water pipelines. Its adaptable and user-friendly design allows for easy installation and removal, complying with the demands of various pipeline specifications. This indicator operates by simply being affixed to the pipeline’s external wall, solving issues associated with mechanical malfunction, a lack of explosion-proof capabilities, and inaccuracies in detection. Moreover, it effectively eliminates the electronic interference that often leads to false positives and false negatives, ensuring reliable and accurate operation.

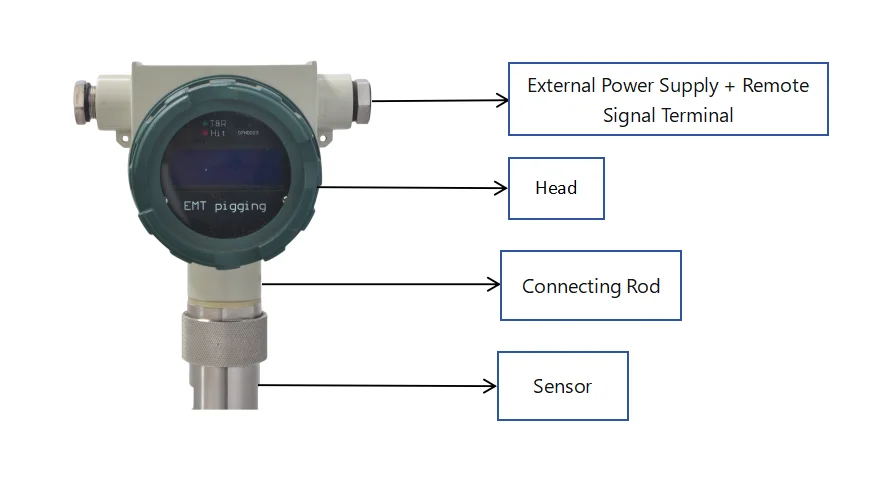

Composition of Non-intrusive Pig Indicator

The Non-Intrusive Pig Indicator is equipped with an explosion-proof remote transmission display mechanism (TZS). This mechanism features an LCD with a heating function, can record passing time, and can store memory up to 99 times. It also supports remote transmission, is marked with an explosion-proof rating of Exd IICT6 Gb, and has a protection level of IP65. Furthermore, the device includes a sensing mechanism, YY-FCT, a detachable card loading mechanism, a connecting wire, and an extension rod, typically used for buried pipelines.

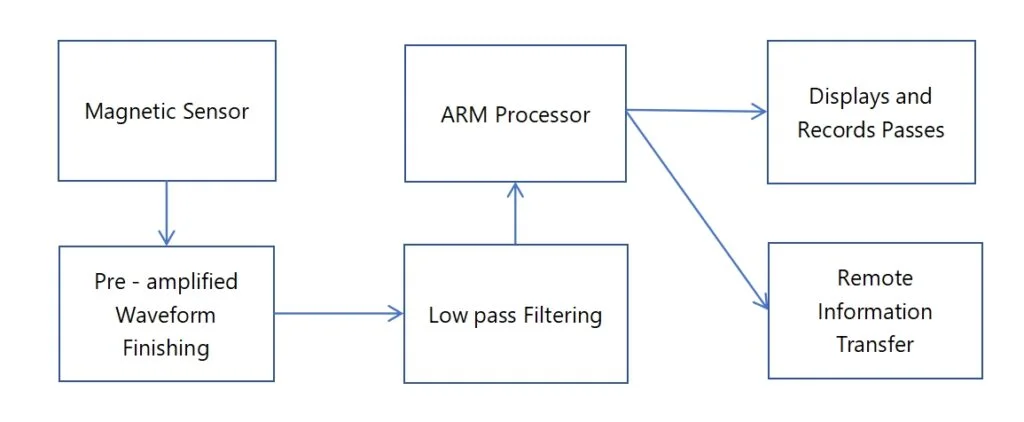

At the heart of the Non-Intrusive Pig Indicator is its core sensing mechanism. This mechanism is composed of a directional reluctance circuit, a balanced amplifier circuit, a low-pass filter circuit, and a trigger circuit. It also includes a CPU, a matching remote switching circuit, a display circuit, and a reset circuit, all of which work in unison to ensure the effective and efficient operation of the detector.

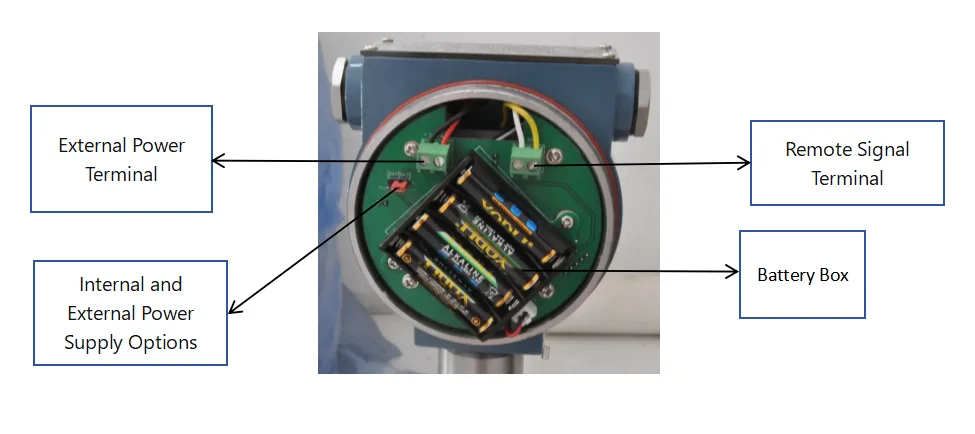

The wiring interface for the device is located on the right side of the screen, typically containing four wires. The black and red wires are the power cables, which can be connected to a DC power supply ranging between 6-24V (with the red wire as positive and the black wire as negative). These wires also allow for switching between internal and external power supply modes.

The remaining two wires serve as ports for the remote signal cables. The white wire acts as the common terminal, while the yellow wire is normally open. If a multimeter is used to test the open state, the standard signal cables would connect only to the common and normally open terminals.

The power interface and the remote transmission interface have a size of M20*1.5 or 1/2NPT, and the conversion connector interface is a 3/4NPTF internal connector.

Working Principles of Non-intrusive Pig Indicator

The Non-Intrusive Pig Indicator operates through a meticulously designed process. It begins with a magnetic sensor, a crucial element that captures the magnetic field alterations as the pig passes through the pipeline. This raw magnetic data is then sent to a pre-amplified waveform finishing stage, which enhances the signal quality by eliminating noise and irrelevant data. The improved signal then undergoes low-pass filtering, a process that further refines the signal by removing high-frequency components and retaining the essential low-frequency information. The filtered signal is processed by an ARM processor, a powerful and efficient component of the indicator, which interprets the data and determines the presence and characteristics of the pig. The final information is then displayed and recorded for future reference, creating a record of the pig’s passes through the pipeline. Each step in this process contributes to the high accuracy and reliability of the Non-Intrusive Pig Indicator.

Parameters of Non-intrusive Pig Indicator

| Number | Project | Parameters |

| 1 | Applicable Temperature | -39.8°C / 80°C |

| 2 | Applicable Humidity | 41%~83% |

| 3 | Detection Direction | Bi-directional |

| 4 | Sensor Type | Magnetic Induction |

| 5 | Signal Switch Type | SPDT |

| 6 | Detection Accuracy | ±2s |

| 7 | Pig Passing Velocity Range | 0.1-20M/s |

| 8 | Contact Capacity | 3A |

| 9 | Reset Type | Automatic |

| 10 | Cable Connector Type | M20*1.5、1/2NPT F |

| 11 | Explosion-proof Rating | Exd IICT6 Gb |

| 12 | Protection-Rating | IP65 |

Installation of Non-intrusive Pig Indicator

Begin the process by securing the Non-intrusive Pig Indicator onto the pipeline.

Choose the appropriate card loading mechanism (clamp) based on the pipeline’s specifications. Securely fix this mechanism in the necessary position. Please note: For pipelines featuring a thermal insulation layer, ensure that the sensing mechanism is attached directly to the metal pipe wall during installation (refer to the clamp installation diagram). Insulation procedures should only be carried out post-installation. For temporary use cases, the device may be installed directly on the insulation layer.

Activation of Monitoring Mode

Once the power supply has been properly installed and selected via the jumper cap, the meter initiates operation. It displays the current time, enters the calibration process, automatically identifies the initial threshold, and then activates the monitoring mode to commence pig monitoring.

To guarantee reliable operation, it is recommended to manually run the detection function once by pressing the corresponding button before each monitoring session. This ensures the device is fully calibrated and ready for accurate pig detection.

Installation and Usage Considerations

- During installation, do not strike the display window with heavy objects. Avoid bringing magnetic materials close to the sensor.

- The pig being detected should be equipped with a magnetic block. If not, one should be installed using the provided additional parts. The installation location should avoid collision with the pipeline and can be placed in the middle or rear part of the pig’s framework.

If space permits, more magnetic blocks can be stacked together and installed on the pig (a minimum of two blocks is required for a 5mm thickness). - When installing the magnetic block on the pig, ensure the circular, flat surface of the magnetic block is parallel to the direction of the sensor base and the pipeline axis (the actual running angle is not necessary to consider). Alternatively, the magnetic block can also be installed to be perpendicular to the sensor base and the pipeline axis. To enhance the magnetic signal sensing capability, install the magnetic block so that the S pole is at the front end of the pig’s operation and the N pole (the side with the installed counterbore) is at the rear end of the pig’s operation.

- For larger pipeline specifications, it’s recommended to use multiple magnetic blocks together. For example, two blocks can be used for a 508 pipeline, and three blocks can be adhered together for an 813 pipeline.

Conclusion

The Non-Intrusive Pig Indicator is a highly efficient and reliable instrument designed for monitoring pigging operations in oil, gas, and water pipelines. Its design is both user-friendly and adaptable, mitigating common issues such as mechanical malfunctions, a lack of explosion-proof capabilities, and detection inaccuracies. The device’s built-in parts, such as an explosion-proof remote display and a complex sensing system, work together to make sure it works correctly.

The installation process of the device is straightforward, with special attention needed to avoid damage to the display window and interference with the sensor. The pig being monitored requires a magnetic block for optimal performance, with additional blocks recommended for larger pipeline specifications. Overall, the Non-Intrusive Pig Detector exemplifies technological advancement in the pipeline industry, enhancing operational efficiency and safety.

Reviews

There are no reviews yet.