Description

Introduction

Non-intrusive Pig Detector is used as a ground judge for pigging oil, gas, or water lines. It is flexible and convenient to install and disassemble and can meet the requirements of all kinds of pipelines on the indicators. It only needs to be fixed on the outer wall of the pipeline to work, which solves the problems of mechanical failure, non-explosion-proof, affecting the accuracy of ball judgment, and electronic interference resulting in false positives and missing positives.

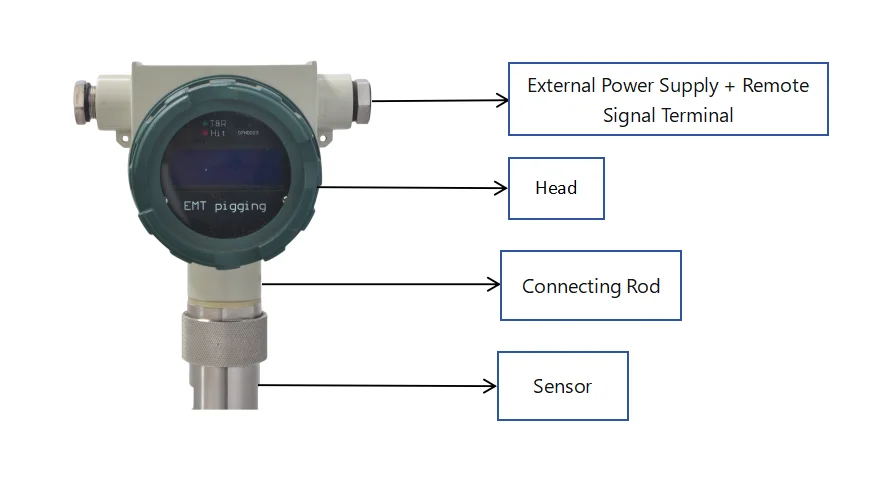

Product Composition

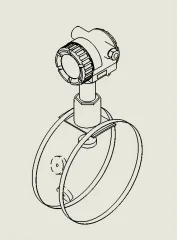

A non-intrusive pig detector is a form of Explosion-proof remote transmission display mechanism TZS (LCD has heating function, record passing time, stores memory 99 times, remote transmission, explosion-proof mark Exd IICT6 Gb, protection level IP65) and sensing mechanism YY-FCT, detachable card loading mechanism, connection wire, extension rod (if necessary, generally buried pipeline).

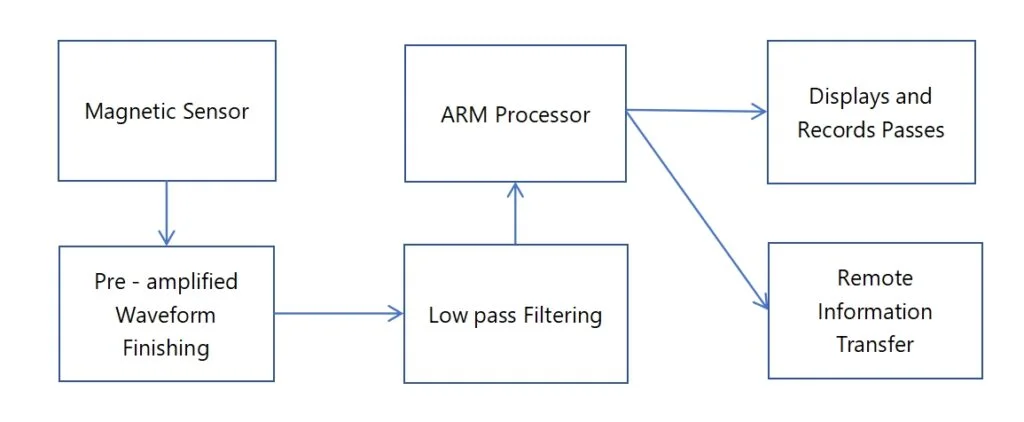

The Non-intrusive Pig Detector core sensing mechanism consists of a directional reluctance circuit, a balanced amplifier circuit, a low-pass filter circuit, a trigger circuit, a CPU, a matching remote switching circuit, a display circuit, and a reset circuit.

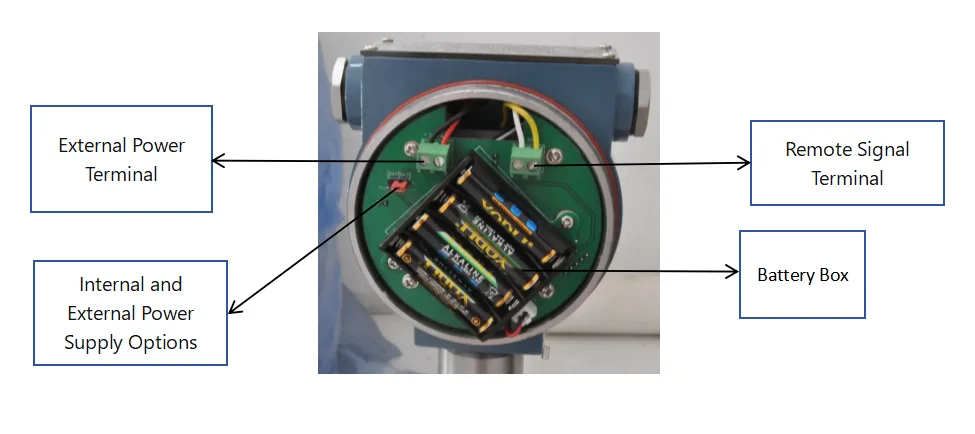

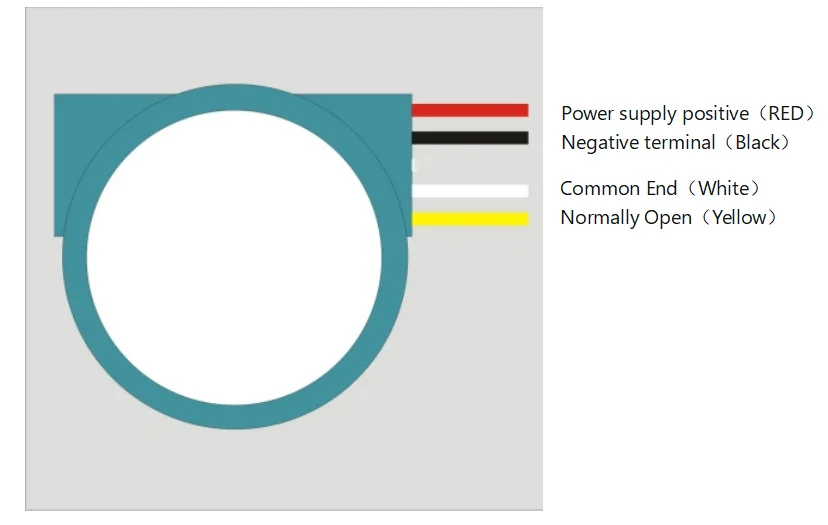

Wiring: Facing the right side of the screen is the wiring interface, usually 4 wires. The black and red cables are power cables, and 6-24 V DC power supplies can be connected (red is positive, and black is negative). Switch the internal and external power supply modes of the power supply. The other two are ports for remote signal cables. The white line is the public end, and the yellow line is normally open. (If a multimeter is used to test the open state, ordinary signal cables connect only to the normal and public ends.) The size of the power interface and remote transmission interface is: M20*1.5 or 1/2NPT, and the conversion connector interface is 3/4NPTF internal connector

Product Working Principle

Parameters of Non-intrusive Pig Detector

| Number | Project | Parameters |

| 1 | Applicable Temperature | -39.8°C / 80°C |

| 2 | Applicable Humidity | 41%~83% |

| 3 | Detection Direction | Bi-directional |

| 4 | Sensor Type | Magnetic Induction |

| 5 | Signal Switch Type | SPDT |

| 6 | Detection Accuracy | ±2s |

| 7 | Pig Passing Velocity Range | 0.1-20M/s |

| 8 | Contact Capacity | 3A |

| 9 | Reset Type | Automatic |

| 10 | Cable Connector Type | M20*1.5、1/2NPT F |

| 11 | Explosion-proof Rating | Exd IICT6 Gb |

| 12 | Protection-Rating | IP65 |

Applied Characteristics

When the product is working, when the pig with magnetic force passes, the time when the pig passes is displayed and a switch signal is transmitted to the pigging process control center to understand the operation of the pig. The display mechanism simultaneously stores the number and time of passing the memory, the memory number: 99 times.

The Non-intrusive Pig Detector stands as a monumental advancement in the sphere of pipeline maintenance and monitoring. This technology is designed to serve as a reliable ground judge for pigging oil, gas, or water lines, bringing a new level of efficiency and effectiveness to the process.

One of the key attributes of the Non-intrusive Pig Detector is its adaptability. It can cater to a wide array of pipeline requirements, thereby offering a high degree of application flexibility. Its easy installation and disassembly further add to its utility, making it a convenient solution for various pipeline conditions.

Wiring Diagram

Installation

- Fix the Pig Detector to the pipeline first

Select the card loading mechanism (clamp) according to the pipeline specifications, and fix the card loading mechanism in the required position. Special note: For pipelines with a thermal insulation layer, the sensing mechanism should be affixed to the metal pipe wall during installation (see the clamp installation diagram), and thermal insulation should be carried out after installation. (Special temporary use, can also be directly installed on the insulation layer)

- Monitor mode activation

After the power supply is installed and selected through the jumper cap, the meter starts to run, displays the current time, enters the calibration procedure, automatically detects the initial threshold, and then starts the monitoring mode to enter the pig monitoring state (in order to ensure reliable operation, the detection function is run once by pressing the button before each monitoring).

Installation and Usage Precautions

- During installation, avoid striking the display window with heavy objects. Do not allow magnetic materials to come close to the sensor.

- The pig to be detected should have a magnet attached. If it doesn’t have a magnet, install one from the provided accessories. The installation location should avoid colliding with the pipeline, and it can be installed in the middle or rear part of the pig frame. If space permits, more magnets can be stacked and installed on the pig. (At least two pieces must be installed for those that are 5mm thick.)

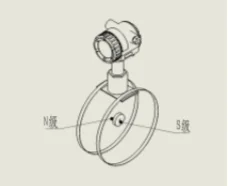

- When installing the magnet on the pig, ensure the flat circular surface of the magnet is parallel to the direction of the sensor base and the pipeline axis (the exact angle during actual operation doesn’t need consideration). Alternatively, you may choose to have the magnet’s flat circular surface perpendicular to the direction of the sensor base and pipeline axis. To enhance magnetic signal induction, install the magnet with the S pole at the front end of the pig’s operation, and the N pole (the side with the mounting hole) at the rear end.

- For larger pipeline specifications, it’s recommended to use multiple magnets. For example, two can be used for a 508 pipeline, and three can be bonded together for an 813 pipeline.

- As needed, an extension rod can be used between the meter head and sensor to increase the installation height of the meter head. The length of the extension rod can be selected and designed according to actual needs.

Conclusion

The product composition of the detector is a testament to its robustness and high functionality. It incorporates an explosion-proof remote transmission display mechanism, a sensing mechanism, and a detachable card loading mechanism. These components work in harmony to deliver a reliable and efficient performance. The display mechanism is equipped with a heating function and the capability to record passing time and store memory up to 99 times. This data storage capacity is crucial for tracking and analyzing pigging operations over time, enabling operators to make informed decisions about pipeline maintenance.

The core sensing mechanism of the Non-intrusive Pig Detector constitutes a directional reluctance circuit, a balanced amplifier circuit, a low-pass filter circuit, a trigger circuit, a CPU, a matching remote switching circuit, a display circuit, and a reset circuit. This intricate design allows the detector to accurately track the movement of the pig, even in cases where the pig has magnetic force.

In conclusion, the Non-intrusive Pig Detector represents a significant stride forward in pigging technology. It offers a comprehensive solution to the challenges of pipeline cleaning and maintenance, delivering crucial data in an efficient, user-friendly format. Its versatility, robust construction, and ease of installation make it an invaluable tool in the modern pipeline industry, promising a future of enhanced operational efficiency and safety.

Reviews

There are no reviews yet.