Description

Introduction of Gauging Plates:

Gauging plates play a crucial role in maintaining pipeline integrity and optimizing pipeline cleaning processes. As a key accessory for pigging systems, these plates offer numerous benefits. In this article, we’ll explore the essential parameters, functions, and advantages of gauging plates offered by EMT, a leading manufacturer of pipeline cleaning solutions.

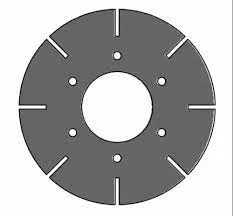

Aluminum gauging plates are utilized in conjunction with steel pig bodies to verify pipe roundness and ensure the absence of excessive weld penetration or debris within the pipeline. When attached to a pig, aluminum gauging plates assist in determining the minimum bend radius before conducting intelligent pig runs.

The outer diameter (OD) of a gauging plate typically ranges from 90% to 95% of the internal diameter of the pipe. Optional slots can be incorporated along the circumferential perimeter of the plate to facilitate easier identification of deformations. The standard construction material for gauging plates is 1/4″ thick aluminum, although mild steel is also a viable option.

Parameters of Gauging Plates:

Gauging plates are specifically designed to fit various pig types. These discs are sized proportionately to the internal diameter of the pipeline and can be customized based on client specifications. The most common material used for gauging plates is aluminum, but steel is also available upon request.

Functions and Use Effects of Gauging Plates:

- Detection of pipeline anomalies: Gauging plates are essential in detecting internal restrictions, such as dents, debris, or out-of-round pipes. These discs help identify issues such as excessive pipeline ovality, dents, excessive weld penetration, and potentially sticking valves during pre-commissioning.

- Pipeline protection: The plates are designed not to damage the pipeline internals while detecting obstructions, ensuring the pipeline’s structural integrity is maintained.

- Smooth entry and extended running distance: Gauging plates provide support during pipeline entry, ensuring smooth insertion of the pig into the pipeline. This support extends the running distance of the pig, improving the overall cleaning process.

- Increased durability: The guide plate enhances the durability of both the front plate and the cup, extending the overall longevity of the pig.

Features and Advantages of Gauging Plates:

- Customizable sizing based on client specifications

- Compatible with various pig types, including foam pigs

- Manufactured from high-quality materials, such as aluminum and steel

- Designed to protect the pipeline during the detection process

- Ensures smooth insertion and extended running distance of the pig

- Increases the durability of the pig, thereby reducing maintenance costs

Frequently Asked Questions:

What material is used for gauging discs?

Gauging plates are most commonly made from aluminum.

Can gauging discs be customized?

Yes, gauging plates can be customized based on your pipeline’s internal diameter and specific requirements.

Purpose of Using Gauging Plates:

The primary use of gauging plates is to work in conjunction with steel pigs in various pipeline applications. Gauging plates, available in both aluminum and carbon steel materials, serve several purposes:

1. Pipe Roundness Verification: Gauging plates are employed to verify the roundness of the pipe. By passing a steel pig equipped with a gauging plate through the pipeline, any deviations from the desired round shape can be identified.

2. Detection of Weld Penetration and Debris: Gauging plates help ensure that there is no excessive weld penetration or debris present in the pipeline. The pig, along with the gauging plate, helps detect any irregularities or obstructions that could impede the pipeline’s operation.

3. Minimum Bend Radius Confirmation: Prior to running intelligent pigs, gauging plates are used to verify the minimum bend radius of the pipeline. This ensures that the pipeline can accommodate the passage of intelligent pigs without any issues.

In summary, gauging plates play a crucial role in pipeline maintenance and inspection by confirming pipe roundness, detecting weld penetration and debris, and ensuring compliance with minimum bend radius requirements.

Application of Piping Pigs with Gauging Plates

The application of piping pigs with gauging plates is prevalent in the petroleum industry, where they have traditionally been employed to clean large-diameter pipelines. However, in an effort to enhance efficiency and reduce costs, smaller diameter pigging systems are now increasingly utilized in continuous and batch processing plants.

Pigging systems find application in various stages of the transfer process within industries handling a diverse range of products such as lubricants, paints, chemicals, cosmetics, and food. They serve purposes such as cleaning pipes to prevent cross-contamination during tasks like lubricating oil or paint mixing. Additionally, they aid in emptying pipes into product tanks or redirecting components back to storage tanks. Typically, pigging is conducted at the beginning and end of each batch, with occasional mid-batch operations. For instance, during the production of premixes utilized as intermediate components.

Moreover, pipe pigs with gauging plates are instrumental in cleaning oil and gas pipelines. “Smart pigs” are specifically designed for leak detection, which is crucial due to the potential explosiveness and environmental hazards associated with pipeline leaks. Generally, production is not interrupted during smart pig inspections, although some product loss may occur during the pig extraction process. Furthermore, piping pigs with Gauging plates are employed to separate different products in multi-product pipelines.

Conclusion:

Gauging plates, available in aluminum and carbon steel variants, are utilized alongside steel pigs to verify pipe roundness, detect excessive weld penetration or debris in the pipeline, and ensure compliance with the minimum bend radius before intelligent pig runs. These gauging plates have outer diameters ranging from 90% to 95% of the internal diameter of the pipe. In some cases, slots may be cut along the circumferential perimeter of the plate to facilitate easier identification of deformation. The thickness of the gauging plate depends on the pig’s size and can be 1/8″, 1/4″, 3/8″, or 1/2″. While the standard material for gauging plates is aluminum, steel can also be utilized.

Gauging plates are an indispensable accessory for efficient pipeline cleaning processes. By utilizing EMT’s high-quality gauging discs, you can detect pipeline anomalies and extend the life of your pigging system. Don’t compromise on the performance and longevity of your pipeline cleaning equipment; invest in EMT’s gauging discs and experience the difference in efficiency and durability. Contact EMT’s team of experts today to find the perfect solution for your pipeline cleaning needs.

Reviews

There are no reviews yet.