Description

Introduction

The welded pig indicator showcased is an advanced, removable model, demonstrating an enhanced level of adaptability due to its intrusive and mechanically controlled design. It is secured within the pipeline system through a welded connection, ensuring stability and durability in operation. A distinctive feature is its manual reset flag, which works in conjunction with an electrical signal to provide a comprehensive signaling mechanism. This flag can be manually adjusted, and the signaler itself can be conveniently removed with a standard retriever, reducing the complexity of maintenance tasks.

This bi-directional signaler has a flag indicator that is typically arranged in horizontal and vertical positions. When a pig traverses the system, the flag’s manual latch system triggers it to return to a horizontal position. This action facilitates real-time tracking of a pig’s progression through the pipelines, providing valuable data on its location and timing.

The pig signaler’s design also enables the estimation of debris accumulation ahead of the pig. This feature is instrumental in pinpointing specific pipeline sections prone to debris buildup, which further aids in targeted maintenance and operational efficiency. An integral component of this pig signaler is the isolation valve, which plays a crucial role in controlling fluid flow, enhancing efficiency, and, most importantly, mitigating leakage. If there is a leak, the isolation valve can be quickly turned on to cut off the affected area. This keeps the system from being damaged all over and saves valuable resources.

Characteristics of the Welded Pig Indicator

The Welded Pig Indicator is a critical element in pipeline engineering, bringing together a range of features that optimize its efficiency and reliability. One of its notable characteristics is its secure welded construction, which contributes to its robustness and ability to withstand rigorous pipeline environments. This secure connection minimizes potential operational failures and ensures a stable interaction with the pipeline system.

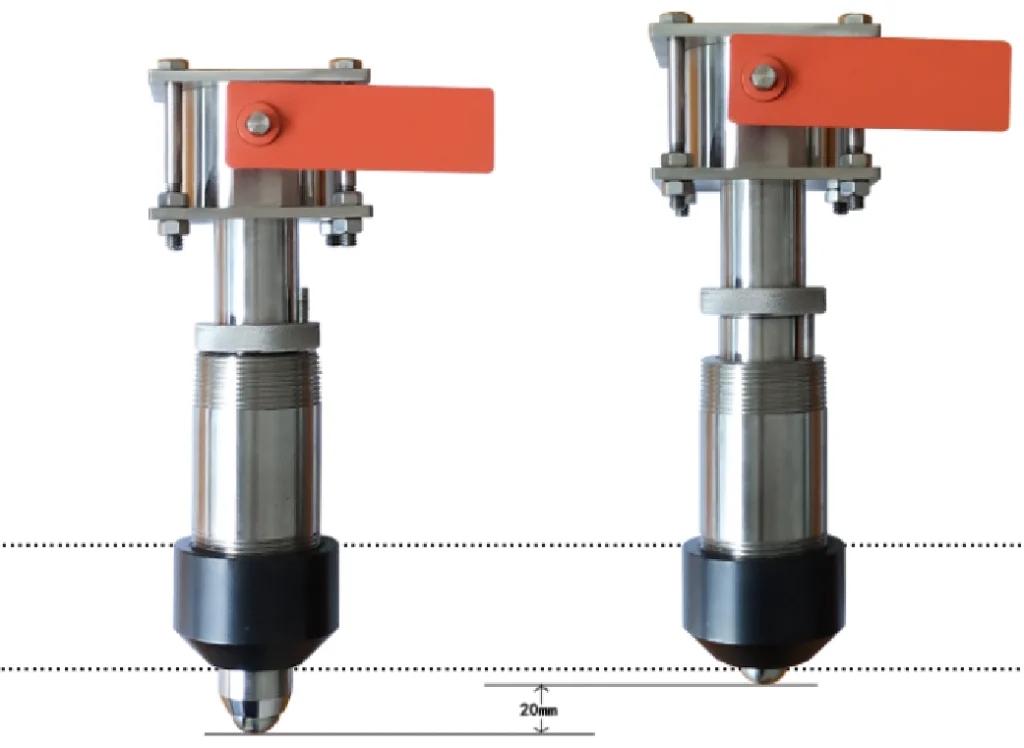

The operational design of the Welded Pig Indicator is focused on precision and adaptability. It’s engineered to detect the passage of a pig through the pipeline swiftly and accurately, providing essential data about the pig’s location and pipeline status. With an adjustable probing depth of its pin ranging from 0 to 10 mm, the indicator is very flexible and can be used with a wide range of pipeline infrastructures. Its non-electrical nature and design ensure minimal friction between metal components, enhancing safety in volatile environments. Therefore, the Welded Pig Indicator, with its robust structure and adaptable features, stands as a crucial tool in pipeline engineering.

Main Technical Specifications of the Welded Pig Indicator

- Type: Intrusive

- Connection type: Welded connection

- Indicator feature: Manual reset flag( Manual reset flag combined with electrical signals and Date and time display combined with electrical signals can meet customer needs)

- Installing type: 2”Welded base, NPT connection Design pressure up to 3000 Psi

- Trigger type: Uni-directional

- Insert depth( In pipe): 13mm

- Plug body length: set

- Insert depth adjustment: 20mm

- Operating temperature: -20~ 120℃/ Meet customer requirements (composite value may vary for specific media)

- NACE MR 0175: Yes

- Ingress protection: IP66

- Explosion-proof class: Exd II BT4

- Include isolation valve: No

- Remove under pressure: Yes

- Retriever: Special retriever

- Internal part material: 316SS is the standard configuration (DSS and INCONEL can also be provided)

- Nipple/Body material: A105 is standard configuration (304SS/ 316SS/ DSS/ INCONEL or other materials can meet customer needs)

Installation and Inspection of the Welded Pig Indicator

The installation process of the welded pig indicator begins with adjusting the extension length of the trigger according to the thickness of the pipeline wall. This is achieved by rotating the movement, ensuring the trigger is positioned between 0-3mm above the pipeline’s inner wall. The relative position (distance from the top of the movement display seat to the top of the base) is then recorded. The pig indicator, with the adjusted extension length, is inserted into the pipeline opening, perpendicular to the pipeline. A point is then welded at the joint for positioning. In cases where the base’s step cannot autonomously complete the insertion depth positioning, manual positioning is required during welding. The movement is then unscrewed from the base and stored in a clean packaging box. According to the welding requirements, the base is securely welded to the pipeline. Once the base has cooled, lubricating oil is applied to the sealing surface of the movement and the base, after which the movement is reassembled onto the base. Finally, the locking nut is tightened to create an external seal and prevent the movement from rotating.

Working Principle of the Welded Pig Indicator

A bidirectional trigger extends into the interior of the pipeline at the pipe wall at the end of the movement, positioned on the base. When the pipeline pig goes by, the trigger pin is actuated, pushing the link rod and causing the flag indicator cap to pop up. When the flag turns in direction, it remains sprung up until manually reset, signifying that the pipeline pig has passed.

The trigger pin will automatically reset when the pipeline pig has passed. At this point, forcibly pressing down on the flag indication cap will reset it, placing it in standby mode. If tapping the flag indication cap does not reset it, it means that the pipeline pig is at this place and the trigger pin has not been reset.

Maintenance

The welded pig indicator employs a non-metallic sealing ring between the base and the movement for pipeline medium sealing. Following installation, the sealing surface automatically conforms to the dimensions of the movement and base sealing surfaces. Should off-site repair or replacement necessitate the disassembly of the movement, a small lever like a flat-blade screwdriver can be used. This tool is inserted into the ring groove at the upper part of the sealing ring for careful removal. The removed sealing ring should be labeled, including machine position and time, and stored for future use when the original movement returns. For the installation of a new movement on the original base, a fresh seal ring should be utilized.

Upon the utilization of a new sealing ring, it can be reused exclusively with the movement it originally accompanied. This implies that a used sealing ring can be reinstalled with the movement on other compatible bases.

If a leak is detected at the sealing ring, an initial examination of the lock nut’s tightness is necessary. If the lock nut is secure, the likelihood is that the sealing surface was not adequately cleaned during the installation, leading to a compromised seal. This issue necessitates a reinstallation after the pipeline is shut down and depressurized. The need for a new sealing ring is contingent upon the circumstances during the reinstallation process.

In the event of contamination of the Pipeline Engineering Pig Signaller by viscous materials, the stainless steel cylinder should be removed initially. Subsequently, all components of the stainless steel cylinder should be disassembled for thorough cleaning.

Conclusion

In conclusion, the Welded Pig Indicator emerges as a vital component in pipeline engineering due to its robust construction, precision, flexibility, and operational safety. Its seamless integration into a variety of pipeline infrastructures and the ability to provide accurate and valuable data make it an indispensable tool in the industry. Furthermore, its design that leans towards minimal friction and the ability to withstand volatile environments enhances its position in the safety aspect of operations.

Maintenance procedures, including the handling of the non-metallic sealing ring and the cleaning process, ensure the longevity and optimal performance of the Welded Pig Indicator. Even in the face of challenges such as leaks and contamination, the guidelines provided ensure that the indicator can be efficiently cleaned, reinstalled, or replaced, maintaining the seamless operation of the pipeline system. Thus, the Welded Pig Indicator stands as a testament to innovative engineering, bridging the gap between operational needs and safety requirements in pipeline systems.

Reviews

There are no reviews yet.