Description

Introduction

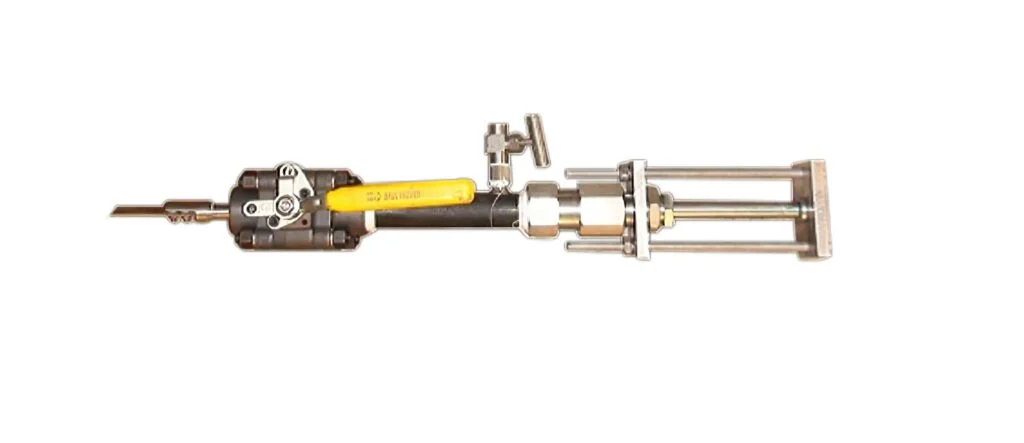

The EMT-RCC Retractable Corrosion Coupon System comes with a clamp-style installation and removal tool that makes it possible to take the system apart online for pipelines that are designed to work at pressures below 10 MPa. This system can operate at pressures up to 1500 psi (10.3 MPa) and temperatures as high as 500°F/260°C. During operation, the implantation depth of the corrosion coupon probe can be adjusted to accommodate the pipeline’s diameter and wall thickness. The standard system is available in various lengths—24, 30, 36, 42, and 48 inches—making it suitable for pipes of different diameters. At its extremity, the system can hold an insulated strip-type corrosion coupon. The corrosion coupon system comprises a probe rod, a ball valve, a corrosion coupon, and an adjustable safety clamp kit. It is recommended to use the safety closure when the pipeline pressure drops below 1500 psi and the temperature falls below 500 °F.

Components

- Safety Clamp Assembly: This component ensures that the system is securely fastened to the pipeline. It’s designed to handle the high pressure and temperature conditions that the system operates under.

- Lock Nut: The lock nut plays a crucial role in securing the system and preventing it from loosening due to vibration or pressure changes in the pipeline.

- Sealing Nut: The sealing nut works in conjunction with the lock nut to create a secure and tight seal, preventing any leakage from the pipeline.

- Connection Pipe: This is the section of the system that physically connects the corrosion coupon to the pipeline. It is designed to withstand the same pressure and temperature conditions as the pipeline itself.

- Full Bore Ball Valve: This valve controls the flow of the pipeline medium. It can completely stop or allow full flow, which is crucial for system maintenance and operation.

- Welded Base: The welded base is the foundation of the coupon system, providing a solid and sturdy platform for the other components.

- Coupon Mounting Rod: This rod holds the corrosion coupon in place and is adjustable to accommodate different pipeline diameters and wall thicknesses.

- Corrosion Coupon: The corrosion coupon is the part of the system that monitors the rate of corrosion within the pipeline. It is typically made from the same material as the pipe.

- Adjustment Nut: The adjustment nut allows for the precise positioning of the corrosion coupon within the pipeline. This is crucial for obtaining accurate corrosion data.

- Upper Safety Clamp: This clamp secures the upper part of the system and works in conjunction with the lower safety clamp to ensure the system is firmly attached to the pipeline.

- Locking Nut: The locking nut provides an additional layer of security to the system, ensuring that the adjustments made to the coupon position remain fixed during operation.

- Lower Safety Clamp: This clamp secures the lower part of the system, working in tandem with the upper safety clamp to provide a tight and secure attachment to the pipeline.

Reinstallation of EMT-RCC Retractable Corrosion Coupons

After the corrosion coupon replacement is completed or reinstalled after the inspection work, proceed with the reinstallation of the coupon device.

(1) Confirm whether the adjustment rod is in place.

Measure and adjust the distance between the two safety clamps (important); it should meet L2 = 515~525mm. If it does not meet this criterion, adjustments should be made to this range. (Note: Keep the lower safety clamp stationary during the adjustment process; only adjust the upper safety clamp during the adjustment process.)

(2) Replace the sealing material.

Clear the residual sealing material at the branch pipe threads and the sealing nut, and wrap the new sealing material at the branch pipe threads.

(3) Install the coupon device.

Align the coupon device with the branch pipe threads, hand-tighten until it doesn’t move, then use a wrench to tighten the sealing nut.

(4) Open the valve.

After opening the valve, check whether there is any leakage at the branch pipe connection and other threaded connections. If there is leakage, close the valve, then deal with the leaking seal (replace the sealing material or replace parts, maintain, and reinstall). If there is still leakage, repeat this step until there is no leakage.

(5) Adjust the upper safety clamp to its initial installation position.

Adjust the lower adjustment nut of the upper safety clamp to the lowest position, and promptly adjust this nut when it affects the adjustment of the upper adjustment nut.

Adjust the distance between the upper safety clamp and the surface of the welded base to the initial installation record distance L, see step (4) of the initial installation.

When adjusting the nuts, a single person can operate alternately to tighten the two nuts; or two people can simultaneously tighten the two nuts, trying to keep the upper safety clamp perpendicular to the coupon support rod to avoid excessive tilt.

(6) Lock the Coupon Support Rod.

After the upper safety clamp is adjusted in place, check the direction of the coupon support rod, and turn the coupon support rod so that the indicator surface points in the direction of the pipeline medium flow. Tighten the upper and lower adjustment nuts of the upper safety clamp, and check and tighten the lock nut of the lower safety clamp. Installation is complete.

With this, the reinstallation process ends.

Frequently Asked Questions

Q1: What is a Retractable Corrosion Coupon?

A1: A Retractable Corrosion Coupon is a revolutionary device used for real-time, continuous monitoring of corrosion in industrial settings. It is designed to operate under extreme conditions and can be adjusted to accommodate various pipeline diameters and wall thicknesses.

Q2: What materials are used in the construction of Retractable Corrosion Coupons?

A2: Retractable Corrosion Coupons are constructed from 316 stainless steel, known for its superior corrosion resistance and durability. Other materials can meet customer needs.

Q3: How can the Retractable Corrosion Coupon System withstand high pressure and temperature conditions?

A3: The system is designed to operate at pressures up to 1,500 psi (10.3 MPa) and temperatures up to 500 °F (260 °C). Its robust construction and use of high-quality materials enable it to withstand these extreme conditions.

Q4: What are the standard lengths of the Retractable Corrosion Coupon System?

A4: The system is available in standard lengths of 24, 30, 36, 42, and 48 inches to accommodate pipelines of varying diameters.

Q5: What standards do the Retractable Corrosion Coupons meet?

A5: Retractable Corrosion Coupons meet the stringent requirements of NACE MR0175 and MR0103, ensuring their quality and dependability in various industrial environments.

Conclusion

The EMT-RCC Retractable Corrosion Coupon System is an innovative solution for real-time and continuous corrosion monitoring in industrial settings. Designed to withstand pressures up to 1,500 psi (10.3 MPa) and temperatures up to 500 °F (260 °C), this system offers superior performance in harsh operational conditions. It comes with the flexibility to adjust the implantation depth of the corrosion coupon probe based on the pipeline’s diameter and wall thickness.

With standard lengths ranging from 24 to 48 inches, the system can accommodate a variety of pipeline diameters. Furthermore, the safety clamp assembly ensures safe operation and maintenance, making it an optimal choice for industries looking for reliable and efficient corrosion monitoring tools.

The reinstallation process of the EMT-RCC Retractable Corrosion Coupon is streamlined and well-structured, ensuring minimal downtime and maximum operational efficiency. Built with high-quality materials like 316 stainless steel and complying with stringent NACE standards, this system is designed for longevity and reliability.

In conclusion, the EMT-RCC Retractable Corrosion Coupon System is a revolutionary solution that brings together durability, flexibility, and efficiency, offering an unparalleled corrosion monitoring experience for various industrial applications.

Reviews

There are no reviews yet.