Description

Introduction of Online Corrosion Monitoring System

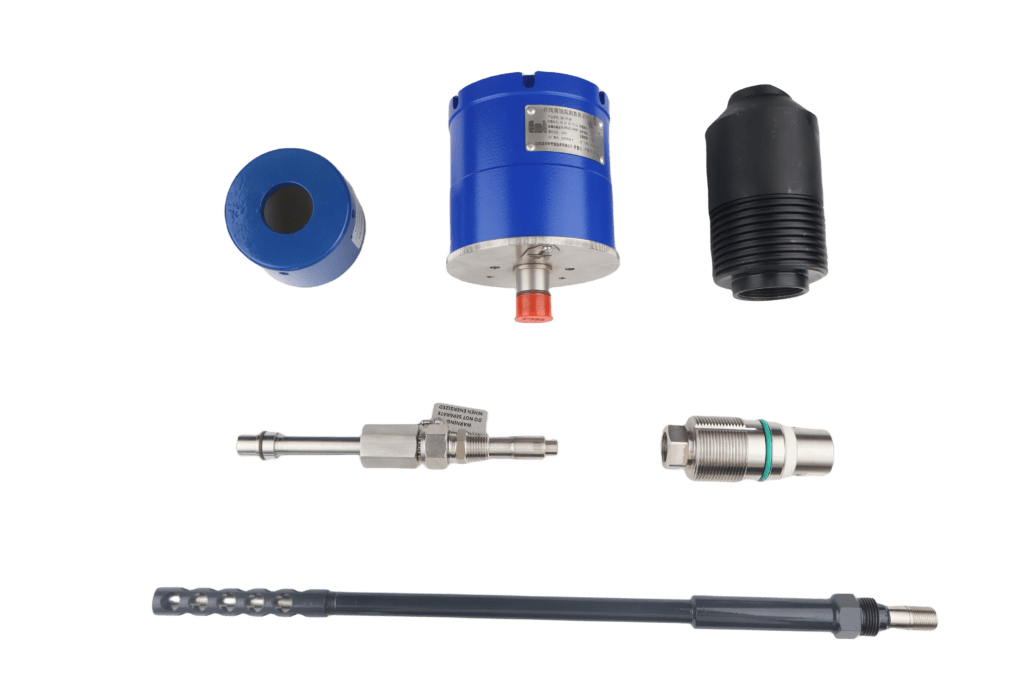

The EMT online corrosion monitoring system operates on its own battery and doesn’t require a cable connection on-site. Corrosion data can be wirelessly imported into our device. Operators can choose the frequency of daily monitoring or select a specific time interval for monitoring. After downloading the EMT software, corrosion monitoring data can be accessed with a single click. The computer automatically calculates the corrosion rate based on the corrosion data and the corrosion rate calculation formula. The pipeline corrosion rate is considered normal if it is less than 0.25 mm per year. If it exceeds this range, safeguards should be implemented to protect the pipeline. This corrosion monitoring device consists of two parts: the collector and the corrosion probe. The collector is an explosion-proof, enclosed structure designed for use in the petrochemical industry.

Installation Process of Online Corrosion Monitoring System

The product installation is divided into two parts: on-site installation and instrument installation.

On-site Installation:

- Welding the Pipeline’s Main Body: Start by welding the main body to the pipeline.

- Tightening the plug: Use a wrench, keeping in mind that this procedure includes a left-hand thread.

- Placing the Assembly in the Pipeline: Before tightening, apply some lubricating oil. Over-tightening can severely distort the sealing ring and impair the sealing effect.

- Attaching the Protective Cover: This prevents the probe from popping out under pressure.

- Installing the Connecting Rod: Keep the critical position in mind during installation. A notch must be attached to the probe’s correct position. This notch is designed to align the position of the probe and connecting rod and prevent the probe from rotating.

- Tightening the Thread: This ensures that the adapter and probe are firmly connected.

Instrument Installation:

- Opening the Instrument Lid: Begin installation by opening the lid of the instrument.

- Inserting the Power Cord: Insert the single power cord into the power socket to power the instrument. Once connected, the indicator light will illuminate briefly.

- Attaching the Protective Cover: This is affixed after the power connection is successful.

- Applying the Sealant: The sealant is for water and explosion protection, and we provide an explosion-proof certificate.

- Connecting the Adapter and Probe: This step is done before tightening the nut. The frequency of data collection can be preset.

- Power Supply: We provide spare batteries or a charger for this battery-powered device.

- Setting Up the Handheld Computer: A matching handheld computer is provided. Install it, turn it off, and the software will automatically start. Once the device is listed online after launching Bluetooth and connecting, the connection is successful.

- Launching the EMT Software: After a successful connection, launch the EMT-specific software to instantly download and read the data.

- Monitoring Corrosion Rate: Normal corrosion occurs when the rate is less than 0.25mm per year. If the rate exceeds this, take measures to slow the corrosion rate of the medium within the pipeline.

EMT Online Corrosion Monitoring System vs. Other Corrosion Monitoring Tools

Corrosion monitoring tools are classified into several types, each with its own set of features and benefits. The EMT Online Corrosion Monitoring System has distinctive features that set it apart from the competition, particularly in terms of its power supply and data transmission systems, which offer users great convenience and operational efficiency.

EMT Online Corrosion Monitoring System Benefits

The EMT Online Corrosion Monitoring System is an advanced tool that is battery-operated, making it much more convenient than offline corrosion monitoring systems. Offline systems often require direct electrical connections, necessitating the installation of multiple cables on-site. These cables must then be connected to other devices, which must then be linked to the company’s local area network (LAN) for data transmission. This process can be time-consuming and may interfere with on-site construction activities, especially if extensive cabling is required.

In contrast, the EMT Online Corrosion Monitoring Device doesn’t require complex cabling. It has a replaceable battery and uses Bluetooth to transmit the data it collects. This method is not only more efficient, but it also has a lower impact on site operations. Data can be downloaded directly onto a device using Bluetooth, eliminating the need for any physical connections. This streamlined process significantly enhances the utility of the EMT Online Corrosion Monitoring Device, making it a highly practical corrosion monitoring tool.

When Should You Use Other Corrosion Monitoring Tools?

While the EMT Online Corrosion Monitoring System has numerous advantages, it’s also important to note that other monitoring tools may be better suited for certain situations or uses. An offline corrosion monitoring system, for example, could be a viable solution in cases where a continuous power source is readily available and extensive cabling is not an issue. Similarly, specialized equipment might be more appropriate for situations requiring monitoring of highly specific types of corrosion or ultra-high-resolution data.

Ultimately, the EMT Online Corrosion Monitoring System offers significant advantages in terms of power supply and data transmission convenience. However, the choice of a corrosion monitoring tool should always be based on a comprehensive evaluation of the specific project requirements, environmental conditions, and other relevant factors. It’s also crucial to consider the cost-effectiveness and compatibility of the tool with the company’s existing systems and processes.

Our Pledge

We at our company place the highest value on customer satisfaction. We proudly present a comprehensive array of Corrosion Monitoring Systems, each tailored to meet a broad spectrum of unique requirements. We encourage you to engage with us to identify the solution that best fits your needs.

Assurance of Quality

We stand by the superior quality of our products and invite our clients to witness this excellence firsthand by requesting sample units.

Customer Support

Our dedicated customer support team is always prepared to swiftly address your inquiries or any issues that may arise. We are committed to providing prompt and effective assistance.

Delivery and Packaging

Recognizing the critical nature of timely deliveries, we are committed to processing and shipping your orders as swiftly as possible. Our online support is available around the clock, seven days a week, to ensure your needs are addressed promptly.

Our products are thoughtfully packaged in CASES that offer several benefits:

CASES are lightweight yet robust, featuring sleek design while offering insulation. They retain their form without deformation. Based on the size of the product, we provide different types of boxes.

For overseas shipping, we safeguard our products in sturdy wooden cases. Before placing the product in the wooden case, we wrap it in soft plastic to mitigate any potential damage during transport.

In all our endeavors, we are dedicated to delivering superior corrosion monitoring system devices swiftly and effectively, with an unwavering dedication to customer satisfaction.

Reviews

There are no reviews yet.