Description

Introduction

This EMT online corrosion detection device comes with its own battery and does not require an on-site cable connection. Corrosion data can be directly imported into our device via Bluetooth. Operators can choose the daily monitoring frequency or the monitoring time interval. After downloading the EMT software, corrosion monitoring data can be downloaded with just one click. The computer will automatically calculate the corrosion rate based on the corrosion data and the corrosion rate calculation formula. If the corrosion rate is less than 0.25 mm per year, the pipeline corrosion rate is normal. If it exceeds this range, measures should be taken to protect the pipeline. This corrosion detection device has two parts. The first is the collector, and the second is the corrosion probe. The collector is a sealed explosion-proof structure suitable for use in the petrochemical industry.

Use Process

The installation of the product is divided into two parts: the on-site installation and the installation of the instrument part.

On-site Installation:

- Welding the Main Body to the Pipeline: Start by welding the main body onto the pipeline.

- Pre-installing the Probe: Tighten the plug with a wrench, noting that this step involves a left-hand thread.

- Inserting the Assembly into the Pipeline: Note: Apply some lubricating oil before tightening. Do not tighten too much, as this can seriously deform the sealing ring and affect the sealing effect.

- Attaching the Protective Cover: This is done to prevent the probe from popping out under pressure.

- Installing the Connecting Rod: Note: Pay attention to the key position during installation. A notch must be connected to the corresponding position on the probe. This notch is designed to determine the position of the probe and the connecting rod and prevent the probe from rotating.

- Tightening the Thread: This ensures a tight connection between the adapter and the probe.

Instrument Installation

Next is the installation of the instrument. Before installation, the cover of the instrument should be opened first. Then, insert the single power cord into the power socket to supply power to the instrument. When successfully connected, the indicator light will light up for a few seconds. Then, cover it with the protective cover.

The role of the full sealant is to provide water and explosion protection. We can provide an explosion-proof certificate.

Then, dock the installed adapter and probe and then tighten the nut. The data collection frequency can be set before the product leaves the factory. The product is battery-powered; we can provide spare batteries or a charger for this product.

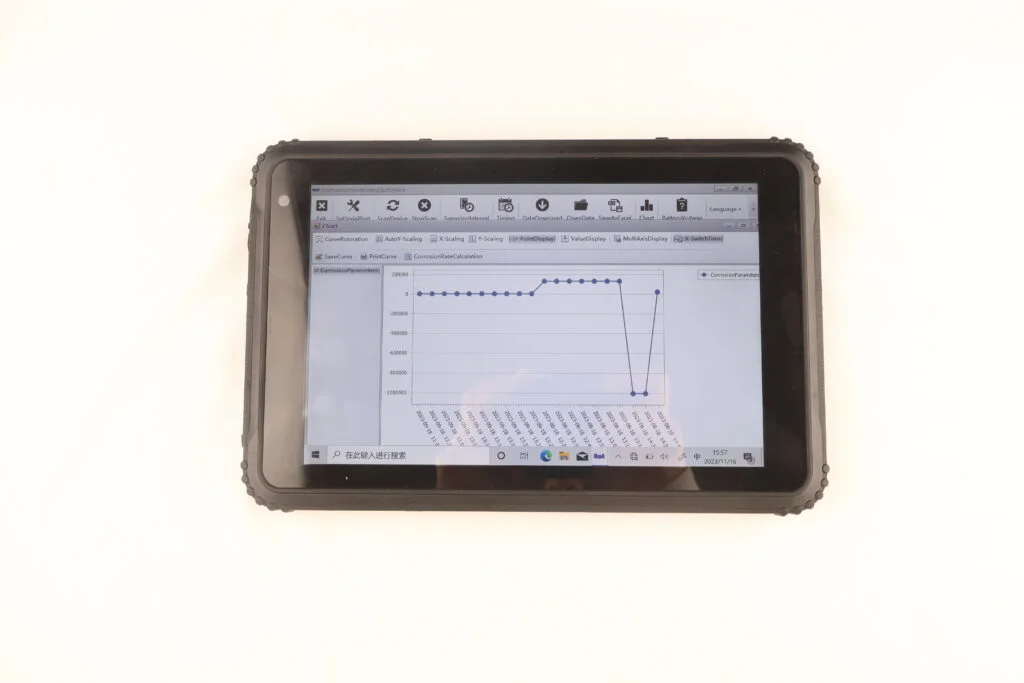

A corresponding handheld computer is provided. After installation, turn off the computer, and the software will automatically start. Upon opening Bluetooth and connecting, if the device is displayed as online, the connection is successful. Then, open the EMT dedicated software, and you can directly download and read the data.

If the corrosion rate is within 0.25mm per year, it is within the normal corrosion range. If the corrosion rate is greater than this value, measures should be taken to slow down the corrosion rate of the medium inside the pipeline.

Comparing EMT Online Corrosion Monitoring Device with Other Corrosion Monitoring Tools

Corrosion monitoring tools come in a range of types, each with its own unique features and benefits. The EMT Online Corrosion Monitoring Device, in particular, offers distinct advantages that set it apart from the rest, especially in terms of its power supply and data transmission mechanisms, which provide users with significant convenience and operational efficiency.

Advantages of the EMT Online Corrosion Monitoring Device

The EMT Online Corrosion Monitoring Device is an advanced tool powered by a battery, making it significantly more convenient than offline corrosion monitoring systems. Offline systems typically necessitate direct electrical connections, demanding the installation of numerous cables on-site. These cables then need to be linked to other devices, which subsequently connect to the company’s local area network (LAN) for data transmission. This process can be time-consuming and may disrupt on-site construction activities, especially when extensive cabling is required.

In stark contrast, the EMT Online Corrosion Monitoring Device eliminates the need for complex cabling. It operates on a battery that can be easily replaced as needed, and the data gathered by the device is transmitted via Bluetooth. This method is not only more efficient but also less disruptive to site operations. With Bluetooth, data can be downloaded directly onto a device, eliminating the need for any physical connections. This streamlined process greatly enhances the usability of the EMT Online Corrosion Monitoring Device, making it a highly practical tool for corrosion monitoring.

When to Use Other Types of Corrosion Monitoring Tools

While the EMT Online Corrosion Monitoring Device offers significant advantages, it’s also important to recognize that other monitoring tools may be more suitable for specific contexts or applications. For instance, in situations where a continuous power supply is readily available and extensive cabling is not a concern, an offline corrosion monitoring system may be a viable option. Likewise, for applications requiring monitoring of very specific types of corrosion or those requiring ultra-high-resolution data, specialized tools might be more appropriate.

In conclusion, the EMT Online Corrosion Monitoring Device provides substantial benefits in terms of power supply and data transmission convenience. However, the choice of a corrosion monitoring tool should always be based on a comprehensive understanding of the specific requirements of the application at hand.

Application of EMT Online Corrosion Monitoring Device

The EMT Online Corrosion Monitoring Device is designed to be versatile, making it suitable for various industries and applications that require stringent corrosion monitoring. Here are a few key areas where its application is particularly beneficial:

- Oil and Gas Industry: In the oil and gas industry, pipelines are extensively used, and their integrity is crucial for safe and efficient operations. The EMT device can help monitor corrosion in these pipelines in real-time, enabling timely maintenance and preventing potential leaks or catastrophic failures.

- Chemical Industry: The chemical industry often deals with corrosive substances. The EMT device can help monitor the integrity of storage tanks and processing equipment, ensuring they maintain their structural integrity and prevent dangerous leaks.

- Marine Industry: In the marine industry, where structures are often exposed to harsh, corrosive sea water, the EMT device can provide critical data on the corrosion rates of ship hulls or offshore structures, supporting preventative maintenance routines.

- Water Treatment Plants: In water treatment plants, where various corrosive chemicals are often used for treatment processes, EMT’s device can monitor corrosion in storage tanks and pipelines, ensuring the longevity of the infrastructure.

- Power Generation Industry: In power plants, particularly in nuclear power plants, the monitoring of corrosion in various components like heat exchangers, boilers, and cooling towers is crucial. The EMT device can provide reliable, real-time data, enhancing the safety and efficiency of these plants.

- Infrastructure: The EMT device can also be used to monitor corrosion in public infrastructure such as bridges, tunnels, and water supply networks. This can help in predictive maintenance, thus ensuring the longevity and safety of these structures.

Reviews

There are no reviews yet.