Description

Maintain Safe Operations and Corrosion Control

Handling and controlling corrosive fluids, such as acids and bases, can be costly due to the significant operating expenses incurred from lost production and maintenance expenditures associated with repairing or replacing damaged equipment, often amounting to millions of dollars. EMT has the largest portfolio of wetted materials and corrosion monitoring solutions to handle your toughest production challenges.

Corrosion is a persistent threat that plagues various industries, causing significant financial losses and safety hazards. In this comprehensive guide, we will delve into the intricacies of corrosion monitoring, exploring its significance, methodologies, and cutting-edge technologies. By implementing the insights shared here, you can safeguard your assets and maintain the integrity of your metal structures.

Understanding Corrosion and Its Implications

Corrosion is a natural electrochemical process that gradually deteriorates metal surfaces due to environmental factors. It is essential to grasp the underlying mechanisms and consequences of corrosion to devise effective monitoring strategies. Some key points to consider include:

1. Mechanisms

Various corrosion mechanisms exist, each influenced by different factors such as moisture, temperature, chemicals, and electrical currents. The most common types of corrosion include:

Uniform Corrosion: This form of corrosion occurs uniformly across the entire surface of the metal.

Galvanic Corrosion: Galvanic corrosion arises when two dissimilar metals come into contact in an electrolyte, resulting in accelerated corrosion of the less noble metal.

Pitting Corrosion: Pitting corrosion manifests as localized corrosion, characterized by small pits or cavities on the metal surface.

Crevice Corrosion: Crevice corrosion occurs within confined spaces or gaps, such as joints, welds, or under deposits, leading to localized damage.

2. Implications

Corrosion can have severe consequences, including:

Structural Integrity: Corrosion weakens the structural integrity of metal components, increasing the risk of failures and accidents.

Financial Losses: Corrosion-related maintenance, repairs, and premature replacements incur significant costs for industries.

Environmental Impact: Corrosion can lead to the release of toxic substances, polluting the environment and endangering ecosystems.

Importance of Corrosion Monitoring

Proactive corrosion monitoring plays a crucial role in mitigating the adverse effects of corrosion. By adopting a comprehensive monitoring program, you can identify potential corrosion issues at an early stage, allowing for timely interventions. Here’s why corrosion monitoring is paramount:

1. Early Detection

Corrosion monitoring enables the early detection of corrosion-related anomalies, providing an opportunity to implement corrective measures before substantial damage occurs. This helps extend the lifespan of assets and reduces maintenance costs.

2. Optimal Maintenance Planning

By monitoring corrosion rates and patterns, maintenance schedules can be optimized, ensuring inspections and interventions are conducted when necessary. This prevents unnecessary downtime and minimizes disruptions to operations.

3. Risk Mitigation

Corrosion monitoring helps identify high-risk areas prone to corrosion, allowing for targeted mitigation strategies. By addressing these areas promptly, the overall risk of failures and accidents can be significantly reduced.

Techniques and Technologies

A range of corrosion monitoring techniques and technologies are available to accurately assess the corrosion rate and severity. Here are some widely employed methods:

1. Electrochemical Techniques

Electrochemical techniques are commonly used due to their versatility and accuracy. These methods include:

Potentiodynamic Polarization: Measures the corrosion rate by examining the current response to varying applied potentials.

Electrochemical Impedance Spectroscopy: Analyzes the impedance response of a metal-electrolyte system to determine the corrosion characteristics.

2. Gravimetric Analysis

The gravimetric analysis involves measuring the weight loss of a metal specimen exposed to a corrosive environment. This method provides valuable data for corrosion rate calculations.

Non-Destructive Testing (NDT)

Non-destructive testing methods allow for corrosion monitoring without causing damage to the metal structure. Some commonly utilized NDT techniques include:

Ultrasonic Testing: Uses high-frequency sound waves to detect flaws, measure wall thickness, and identify corrosion damage in metals.

Radiographic Testing: Involves the use of X-rays or gamma rays to inspect the internal structure of metal components and identify corrosion or defects.

Magnetic Particle Inspection: Utilizes magnetic fields and magnetic particles to identify surface and near-surface defects caused by corrosion.

Eddy Current Testing: Measures changes in electrical currents induced in conductive materials to identify corrosion-related flaws and cracks.

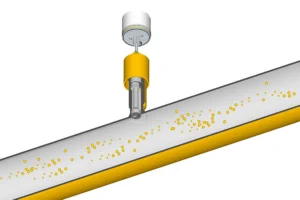

3. Corrosion Coupons and Probes

Corrosion coupons and probes are physical samples or instruments placed in the corrosive environment to monitor corrosion rates. By periodically examining the corrosion products on these samples, the rate of metal deterioration can be determined.

4. Remote Monitoring and Sensor Technologies

Advancements in technology have paved the way for remote corrosion monitoring and real-time data collection. Wireless sensor networks, IoT (Internet of Things) devices, and corrosion monitoring software enable continuous monitoring and data analysis, providing valuable insights for proactive maintenance.

Implementing a Successful Corrosion Monitoring Program

1. Define Monitoring Objectives

Clearly define the objectives of your corrosion monitoring program. Identify critical assets, high-risk areas, and the desired level of corrosion control to guide your monitoring efforts.

2. Select Appropriate Monitoring Techniques

Choose monitoring techniques based on the type of corrosion, environment, and specific requirements of your assets. A combination of techniques may be necessary to gain a comprehensive understanding of the corrosion process.

3. Establish Baseline Data

Collect baseline data to understand the initial corrosion conditions. This provides a reference point for future comparisons and helps identify deviations or abnormal corrosion patterns.

4. Implement Regular Monitoring and Inspection

Consistently monitor corrosion parameters and conduct routine inspections. Regular data collection and analysis enable the detection of any changes or trends, allowing for timely interventions.

5. Analyze and Interpret Data

Thoroughly analyze the collected data to assess corrosion rates, identify potential causes of corrosion, and evaluate the effectiveness of preventive measures. Data interpretation guides decision-making for maintenance and mitigation strategies.

6. Implement Preventive Measures

Based on the findings from corrosion monitoring, implement preventive measures such as coatings, inhibitors, cathodic protection, or changes in operating conditions. Regularly assess the effectiveness of these measures and adjust them as needed.

Conclusion

Corrosion monitoring is an indispensable aspect of maintaining the integrity and longevity of metal structures. By understanding corrosion mechanisms, adopting suitable monitoring techniques, and implementing preventive measures, you can minimize the impact of corrosion on your assets. Safeguarding against corrosion not only saves costs but also ensures the safety, reliability, and sustainability of your operations.

Reviews

There are no reviews yet.