Description

Introduction of the Pipeline Pig Detector

Pipeline Pig Detectors play a crucial role in the maintenance, inspection, and operation of oil, gas, and other types of pipelines. These devices are specifically designed to track and locate pipeline pigs as they traverse the pipeline system. The ability to accurately detect and monitor pigs is essential in mitigating risks associated with pipeline blockages, corrosion, or other potential issues that may lead to operational inefficiencies or even accidents.

Pig detectors come in various types, each with their own unique capabilities and applications. They range from devices designed to detect the presence of a pig to more advanced systems that can provide detailed information about the pipeline’s internal condition. The utility of these detectors extends beyond routine maintenance and cleaning, as they are also used in detailed inspections for early detection of pipeline defects or anomalies.

In this article, we will explore the different types of pipeline pig detectors and delve into their specific features, benefits, and typical applications. By understanding the varying functionalities and uses of these tools, operators can make informed decisions on the best pig detector to use based on their specific pipeline conditions and requirements.

Connection Type

Pipeline pig detectors feature two primary connection methods: flange connection and welding connection.

Flange Connection

Flange connection is a popular method due to its flexibility and ease of maintenance. One of the primary advantages of flange connections is that they facilitate simple assembly and disassembly, making them beneficial for maintenance or modification tasks. They also provide a secure and leak-proof connection, which is critical in maintaining the integrity of the pipeline.

Welding Connection

On the other hand, welding connections offer unmatched durability and reliability. A weld provides a permanent, strong bond that can withstand high pressures and temperatures. This type of connection is particularly advantageous in high-stress environments where a robust and long-lasting connection is paramount.

Triggering Mechanism of the Pipeline Pig

The triggering mechanism of the pipeline pig detectors is categorized into three types: uni-directional, bi-directional, and universal-directional.

Trigger Mechanisms

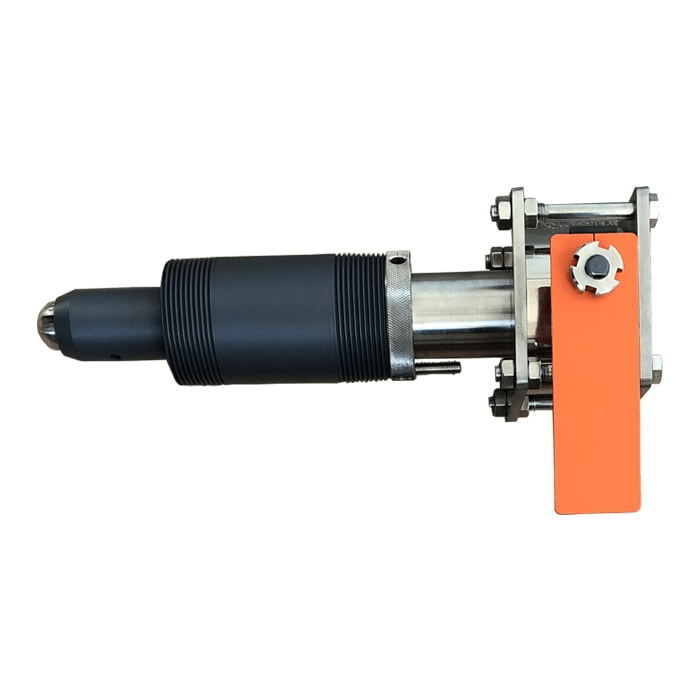

The trigger is a critical component that penetrates the pipeline wall. It reacts when it encounters a passing cleaning pig, prompting the flag to rotate 90° from its horizontal position to an upright state.

Mechanism

The mechanism plays a crucial role in transmitting the trigger’s motion inside the pipe to an external sign or circuit. This transmission is integral to the functionality of the pig detector, enabling the external indication of the pig’s location within the pipeline.

Visible Sign or Electrical Indicator

An externally mounted visible sign or electrical indicator serves as the immediate notification system. This component is typically housed on a pressure vessel, which also serves as an installation site for the triggering mechanism. It doubles as an isolation device, ensuring the secure operation of the detector.

The pipeline pig detector is a sophisticated device with a carefully engineered design. Its construction—from the connection methods to the triggering mechanisms—ensures precise, reliable, and safe operation for pipeline cleaning and inspection tasks.

Working Principle of the Pipeline Pig Detector

The working principle of a pipeline pig detector is rooted in the interaction between the pig moving through the pipeline and the detector’s trigger mechanism.

At the heart of this process is the trigger, which is strategically positioned inside the pipeline near the wall. This location is chosen to allow the trigger to interact with the pig as it passes through the pipeline.

As the pig moves along the pipeline, it comes into contact with the trigger, setting off a chain of events. The trigger is designed to respond to this contact by initiating a magnetic force, which pulls on a flag attached to the detector.

This magnetic force is powerful enough to cause the flag shaft to rotate 90 degrees. Initially, the flag is in a horizontal position, but under the influence of the magnetic force, it moves to an upright position. This dramatic shift in the flag’s orientation provides a visual indicator of the pig’s location within the pipeline.

Observers can then determine the location of the cleaning pig based on the position of the flag. This provides a simple yet effective way to monitor the progress of the pig through the pipeline, ensuring that any cleaning or inspection processes are proceeding as planned.

Once the pig has passed and the monitoring process is complete, the flag can be reset for the next usage. This is done by flipping it counterclockwise and returning it to its original horizontal position, ready for the next pass of the pig.

How Does it Work?

Intrusive pig signalers are permanently mounted onto the pipeline using a specialized fitting, and their location, once selected, cannot be changed. The installation can be done either through a flange or by welding. This type of signaler has a trigger that sticks into the pipe and is mechanically activated when the pig passes by.

Conclusion

In conclusion, pipeline pig detectors are essential tools in the maintenance, inspection, and operation of pipelines across various industries, like oil and gas. They provide valuable insights into the condition of the pipelines, contribute to the early detection of potential defects, and facilitate routine maintenance tasks. The intricate design of these devices, including their connection types and triggering mechanisms, ensures their reliability, precision, and safety in operation.

As we move further into an era of increasing technological advancements, the role of pig detectors in safeguarding pipeline integrity cannot be overstated. Whether it’s the intrusive type permanently installed onto pipelines or the flexible, non-intrusive type, these devices continue to play a critical role in enhancing the efficiency and safety of pipeline systems. By choosing the correct pig detector for their specific needs, operators can ensure the longevity and optimal performance of their pipeline systems.

Reviews

There are no reviews yet.