Description

Introduction to Quick Opening Closures (QOCs)

In plumbing systems spanning numerous sectors, Quick Opening Closures (QOCs) are essential parts. A QOC is a pressure-containing component with a door that allows direct access to the inside of a pressurized vessel or pipe, according to the ASME Sec VIII Div 1 Boiler and Pressure Vessel Code. Its name, Quick Opening Closure, refers to how frequently and swiftly it can be opened and closed. In the oil and gas sectors, QOCs play a crucial role in a variety of operations, including routine maintenance, internal inspection, and the launching and receiving of pipeline pigs. At EMT, we are aware of this. Our QOCs are created to provide accessibility while upholding the greatest safety standards. It is impossible to overestimate the significance of QOCs in a plumbing system since they provide effective access, lower downtime, and guarantee the safety of operational staff.

The Range and Diversity of QOCs

- The range of sizes available (from DN 2” to DN 72”)

- The variety of materials used: Carbon Steel, Stainless Steel, and other materials according to customer needs

- Compliance with international standards: ASME Division VIII, ASME B31.3, ASME B31.4, & ASME B31.8

Orientation and Connection Types in QOCs

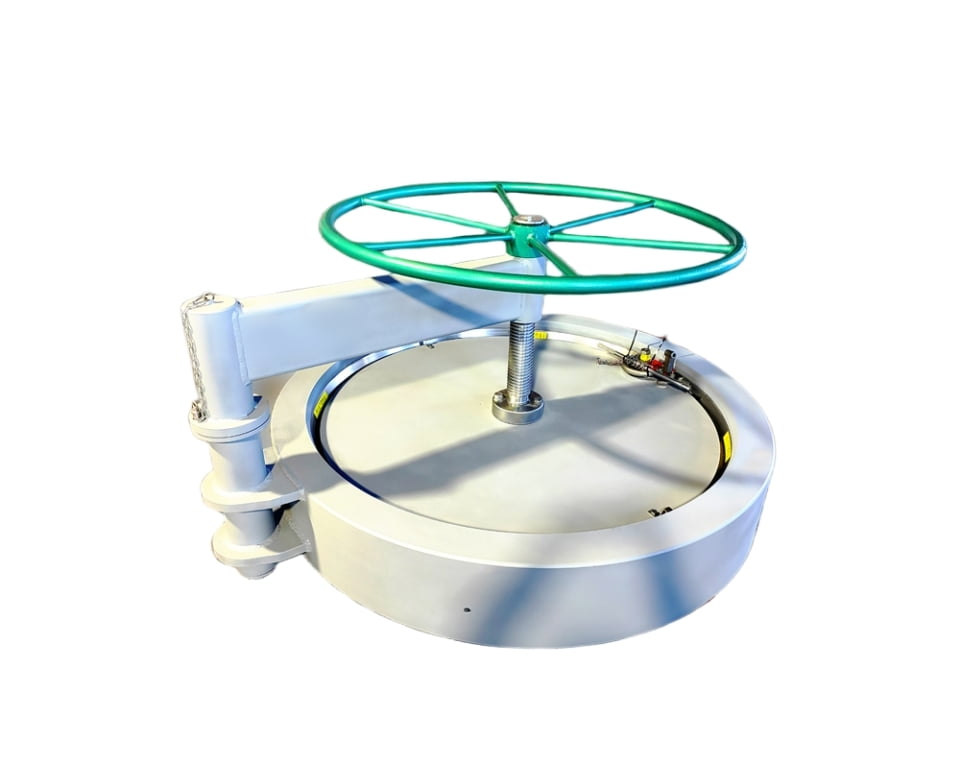

The QOCs from EMT are flexible and may be configured to meet different installation needs. They can be oriented in three different ways: slanted, vertical, or horizontal. Due to their versatility, our QOCs may easily fit into a variety of piping systems. Our closures are primarily employed on pig launchers and receivers, filters, separators, and storage tanks in horizontal applications. On the other hand, tower vessels and vertical separators frequently use vertical applications. In inclined applications where the vessel or pipeline is mounted at an angle, our QOCs can also be employed.

EMT offers full and reduced access designs for connection types. Full access closures are the best option for applications that call for extensive interior access because they provide the largest opening for access to the pipeline or vessel. While offering a smaller opening, reduced access closures offer a more compact design and are often quicker to open and close. We provide mitered designs for inclined or declining containers. These closures are made particularly to accommodate the pipe’s angle, resulting in a flawless fit and effective functioning. In order to ensure the greatest levels of operational efficiency and safety, we at EMT work hard to create solutions that are specifically customized to each project’s requirements.

Essential Accessories and Enhancements for QOCs

At EMT, we are aware that the Quick Opening Closures’ (QOCs’) capabilities go beyond only allowing access to a pipe or vessel’s interior. They can act as a base for a range of supplemental elements that improve the system’s usability and functionality.

Sight glasses for visual examination without opening the closure, nozzles for introducing or extracting fluids, drains for draining liquids, gauges for monitoring pressure, and sampling ports for taking fluid samples for analysis are all accessories that are available for our QOCs. The effectiveness and adaptability of the system can be considerably improved by these additions.

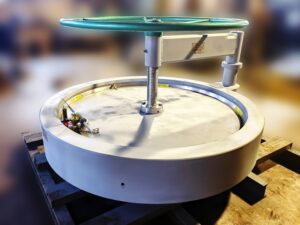

New Developments and Innovations in QOC Design

EMT is pleased to present its unique QOC system as part of our ongoing quest for excellence. This new system demonstrates our dedication to efficiency, safety, and innovation.

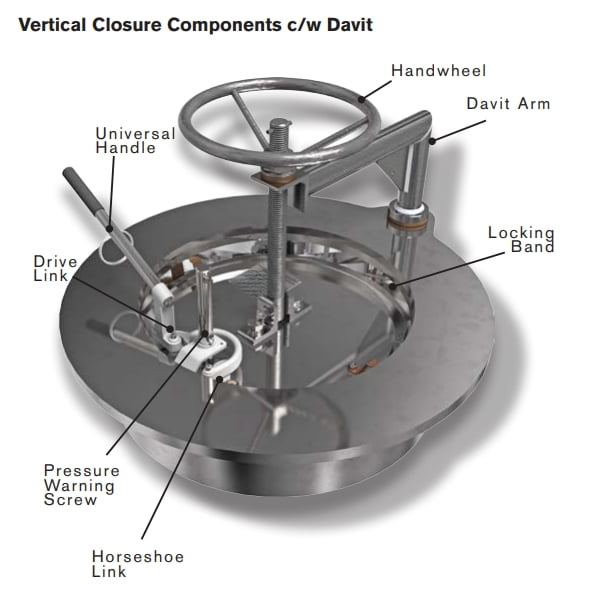

The conventional closing design has several improvements thanks to our unique QOC mechanism. The system has safety features that significantly lower the possibility of accidents occurring while it is in use. In order to operate the closure with the least amount of effort and time, we have also streamlined the operation process.

By integrating the locking mechanisms, the enhanced design creates a lock that is strong, secure, and resistant to high pressure. In order to prevent internal components from corroding owing to adverse weather conditions, the system additionally includes weather seals. Our closures’ dependability and lifespan are ensured by built-in rust prevention.

Role of QOCs in different Working Mediums

Oil, gas, and water are just a few of the various working media that EMTs QOCs are capable of handling. Our closures are suited for a variety of industries, including oil and gas, water treatment, and more because of their versatility.

Our closures are designed to endure the difficulties presented by these various media. For example, they can withstand the high pressures frequently seen in oil and gas systems as well as the corrosive properties of some water systems.

No matter the working environment, our QOCs uphold a high standard of safety and effectiveness. They are suited for a variety of working circumstances since they are built to perform dependably over a wide temperature range, from -50°C to 300°C.

With the help of these developments and improvements, EMT hopes to offer QOCs that satisfy the various demands of our customers while maintaining safety, dependability, and effectiveness across a range of working environments and industry applications.

Conclusion

In conclusion, Quick Opening Closures (QOCs) exhibit adaptability and utility by being used in a wide range of applications across numerous sectors. They play a crucial role in routine maintenance, internal inspections, and other key pipe system operations. Because of its versatility and smooth integration into various orientations and connection types, our QOCs are an essential tool in a variety of operating scenarios. EMT’s QOCs stress safety over efficiency when designing them. Our closures’ operational capabilities are further improved by our incorporated safety measures and the extensive selection of accessories that are readily available. Our QOCs’ capacity to deal with various working media, including water oil, and gas, further demonstrates their adaptability and suitability for a range of operational settings.

We at EMT are still committed to advancing QOC design as we look to the future. In this endeavor, our unique QOC system offers a substantial advancement by providing enhanced operational convenience and safety precautions. In order to increase safety, efficiency, and longevity, we will keep coming up with new ideas and improving our designs. EMT is committed to offering QOC solutions that not only meet but also surpass our client’s expectations in the dynamic environment of industry needs. We are dedicated to supplying goods that uphold the highest standards of quality and safety because we recognize how crucial it is to have dependable and secure access to pressurized containers and pipelines. Customers can anticipate a product that is strong, dependable, and prepared for upcoming problems with EMT’s QOCs.

Reviews

There are no reviews yet.