Description

Introduction of Pipeline Pigging

Pipeline pigging, the practice of using devices known as “pigs” to conduct maintenance operations within a pipeline, is of paramount importance, particularly in the oil and gas industry. This process, which includes tasks such as cleaning the pipeline, inspecting its integrity, and removing accumulated deposits, ensures the efficient flow of transported products. In the oil and gas sector, pigging is crucial for maintaining efficiency, safety, and pipeline longevity. By eradicating debris and other unwanted deposits, it guarantees an unobstructed flow of oil or gas. Furthermore, regular pigging inspections provide vital insights into the pipeline’s condition, allowing early detection of potential issues such as cracks or corrosion. This proactive approach prevents expensive downtime and potential environmental incidents, extends the pipeline’s operational life, and reduces operational costs, underscoring pigging’s essential role in optimal pipeline performance and environmental safety.

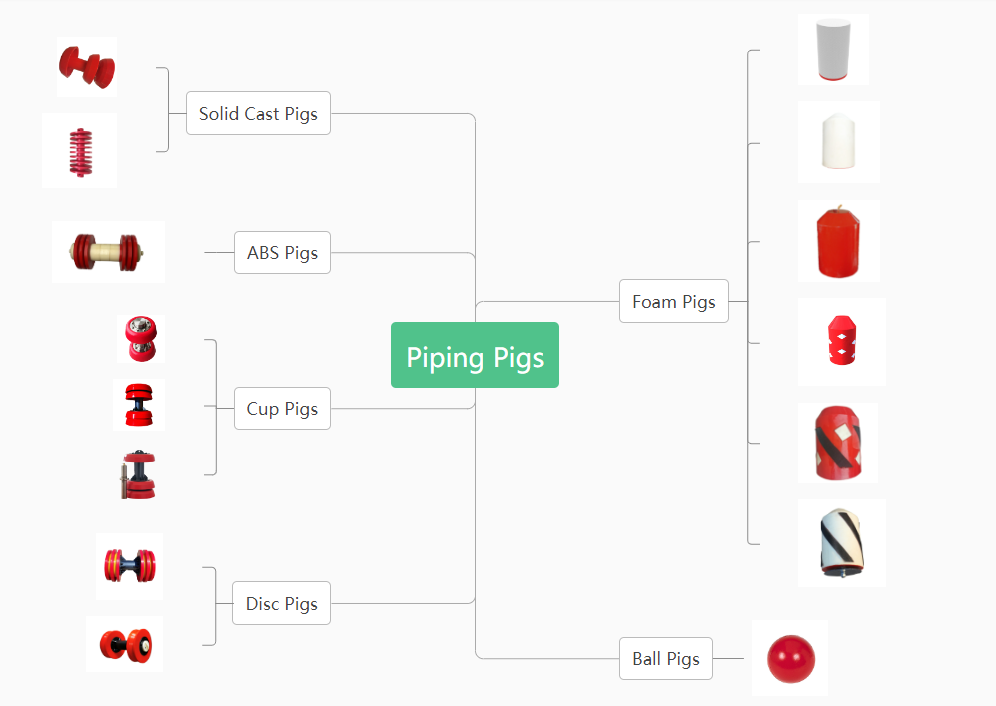

Pipeline Pigging: Basics and Types of Cleaning Pigs

Mechanical Pig

Pigs for Mechanical Cleaning with Cups:

Mechanical cleaning pigs with cups from EMT are designed with a steel frame and 2-4 or more sealed cups, as well as an optional electronic location transmitter. These pigs excel at removing pipeline debris such as stones, wood bars, and more. They are used in pre-production pigging, nitrogen replacement, water pressure testing, and drainage, among other applications. They can be used with a variety of mediums, including crude oil, product oil, edible oil, natural gas, LNG, chemical materials, coal water slurry, sewage, and running water. Their robust sealing capabilities and working range of 100-150 miles make them a reliable solution for a wide range of pipeline cleaning needs.

Pigs for Mechanical Cleaning with Discs:

EMT mechanical cleaning pigs with discs have a steel frame, two guiding discs, four to six sealing discs, and an electronic positioning transmitter. They are effective at removing scale, wax, and deposits from pipes. These pigs are designed for pipeline cleaning, water discharge, water blockage, dielectric isolation, and other applications. They can handle a variety of mediums, including crude oil, product oil, edible oil, natural gas, LNG, chemical compounds, coal water slurry, sewage, and running water, and can function bi-directionally.

Foam Pigs

Foam pigs, which come in a variety of densities and forms, provide adaptable and cost-effective alternatives for pipeline cleaning. The basic type, the Bare Foam Pig, is made of a sponge-like substance and can bend up to 60% to navigate minor radius curvatures. It excels in sweeping, dewatering, and drying pipes. Another variety, the Criss-cross Foam Pig with Brush, is intended to remove tough dirt and deposits, making it perfect for first cleaning procedures.

Because of its spiral wire brushes, the Heavy Density PU Fully Coated Polly Scraper Foam Pig With Spiral Wire Brushes provides better cleaning performance for rust and sludge removal in long-distance pipes. Finally, the Medium Density Polyurethane Bare Polly Foam Pipeline Pig Swab with Brushes combines the benefits of bare foam pigs with the addition of brushes for improved cleaning effectiveness.

These foam pigs have various advantages, including their light and flexible construction, accurate location monitoring, good wear resistance, effective cleaning performance, and low cost. These characteristics make foam pigs an invaluable tool for pipeline repair.

Spherical Pigs

Spherical pigs, hollow round balls made of materials like polyurethane or rubber, have reemerged as valuable tools in natural gas pipelines. Although initially used to remove liquids like water and condensates, their use decreased due to regulatory changes and the implementation of liquid-separation equipment. However, the need to extract liquids from rich-gas collection systems in shale plays is fueling the resurgence of spherical pigs.

These spherical pigs, equipped with inflation valves, excel at displacing liquids within pipelines. They are renowned for their ability to roll into launch positions, enabling automated loading and release of multiple pigs using launch pins. This automation saves time, reduces costs, and cuts gas emissions.

Non-inflatable spherical pigs are also available, and due to their flexibility, they are more suitable for low-flow situations. However, because of their round shape and weight when filled with liquid, special handling equipment is necessary to manage spherical pigs.

Solid Cast Pigs

Solid cast pigs, made from robust polyurethane, are specifically designed for pipeline maintenance and deliver exceptional cleaning performance. These skeleton-free tools can clean and descale pipelines of varied diameters and imperfections due to their solid structure. They are versatile, being used in pipelines carrying water, gas, oil, and chemical reagents. Their sturdy and adaptable design facilitates smooth travel within pipes, helping ensure pipeline integrity. Whether the need is to remove debris, scale, or any other buildup, solid cast pigs offer a reliable and practical solution for pipeline cleaning.

Constructed from high-quality polyurethane, a material revered for its strength and durability, solid cast pigs can withstand the extreme conditions often encountered within pipelines, such as high pressures, abrasive materials, and corrosive fluids. This material strikes an ideal balance between rigidity and elasticity, enabling these essential maintenance tools to perform consistently, even under adverse conditions.

How Pipeline Pigging Works

The pipeline pigging process commences with the placement of the pig into the pipeline via a specially designed piece of equipment known as a pig launcher. This launcher is essentially a sealed-off segment of the pipeline with an entry point for the pig. Once the pig is securely placed within the launcher and the launcher is sealed, the pressure of the fluid or gas being transported through the pipeline propels the pig forward. In certain scenarios, especially in multi-product pipelines, a batch of another product or a buffer fluid might be utilized to aid the pig’s movement.

As the pig navigates through the pipeline, it undertakes its assigned task. This might involve cleaning by scraping off buildup on the pipeline’s inner walls, inspection by measuring the wall thickness and identifying signs of damage, or separation by displacing different products within the pipeline. The pig’s specific role determines its appearance and materials.

The pig continues its journey along the pipeline until it arrives at the pig receiver, another piece of specialized equipment similar to the pig launcher, located at the end of the pigging run. The receiver has been engineered to safely and efficiently remove the pig from the pipeline.

If the pig is a “smart pig,” one equipped with sensors and data recording equipment, the data it has collected is retrieved and analyzed to determine the pipeline’s condition. This analysis could reveal signs of corrosion, cracks, or other potential problems necessitating maintenance.

Following the pig’s removal, it may be cleaned, inspected, and prepared for the next pigging operation. Any maintenance identified as necessary during the pigging operation is also performed to ensure the pipeline’s continued safe and efficient operation. The pipeline pigging process may be repeated at regular intervals to maintain the pipeline’s integrity and efficiency, or it may be performed as needed based on the pipeline system’s specific operational demands.

Applications and Significance of Pipeline Pigging

Pipeline pigging is a crucial process in the operation and maintenance of pipelines, with applications ranging from cleaning and pre-commissioning to routine maintenance and repair. In cleaning, pigs are sent through the pipeline to remove obstructions or potential corrosion triggers, aiding in the maintenance of pipeline efficiency and longevity. The pre-commissioning phase involves a comprehensive cleaning to remove construction debris and rust, priming the pipeline for safe operation. Regular pigging for maintenance can detect early signs of damage or corrosion, facilitating proactive repairs and preventing catastrophic failures.

Pigging also plays a pivotal role in gauging operations and pipeline drying. Gauging pigs, designed to match the pipeline’s minimal internal diameter, are used to identify any internal bore restrictions, ensuring the smooth flow of the product. After hydro testing or other water-involved operations, pigging is used to dry and dewater the pipeline, with foam pigs typically being employed due to their excellent water absorption capabilities.

In terms of pipeline integrity management, inspection or ‘smart’ pigs are instrumental in detecting anomalies such as cracks, corrosion, or wall thinning. This allows for early detection and remediation, enhancing pipeline safety and reliability. Beyond these applications, pigging is also used for product separation, product displacement, and batching. The versatility and wide-ranging applications of pigging make it an indispensable component in the operation and maintenance of pipelines.

Conclusion

Recap of the importance and versatility of pipeline pigging

Pipeline pigging plays a vital role in various aspects of pipeline operations and maintenance. It is fundamental for cleaning pipelines, both during pre-commissioning and regular maintenance, to ensure optimal flow and prevent corrosion. Pigging helps in the early detection of damage, enabling proactive repairs for maintaining pipeline integrity. It aids in identifying internal bore restrictions, ensuring efficient pipeline operations. Pigging is also used for drying and dewatering pipelines post-water-involved operations. With ‘smart’ pigs, it extends to inspecting pipelines for potential anomalies. Hence, the importance and versatility of pigging in pipeline management are significant, contributing to operational efficiency, safety, and cost-effectiveness.

The role of pigging in ensuring pipeline safety and efficiency

Pigging plays a crucial role in ensuring the safety and efficiency of pipeline operations. By cleaning the pipeline, pigging helps maintain optimal flow and prevents blockages, thereby improving efficiency and reducing the risk of disruptive and potentially dangerous ruptures. In terms of safety, ‘smart’ pigs are used for pipeline inspections, detecting early signs of damage such as corrosion, cracks, or wall thinning. This allows for timely repairs, preventing severe failures and ensuring the pipeline’s safety and longevity. Furthermore, pigging aids in managing pipeline integrity by identifying internal bore restrictions and dewatering pipelines after operations involving water. Therefore, pigging is an essential process that significantly contributes to both the safety and efficiency of pipeline operations.

Closing thoughts on the significance of routine maintenance and inspection in the oil and gas industry.

Routine maintenance and inspection play an indispensable role in the oil and gas industry. These processes not only ensure the operational efficiency and longevity of crucial infrastructure but also safeguard against potential hazards and costly shutdowns. Regular maintenance, including activities like pigging, helps maintain optimum flow rates, prevent blockages, and mitigate corrosive damage. Inspections, particularly using ‘smart’ pigs, enable early detection of anomalies or signs of damage, allowing for timely repairs and preventing catastrophic failures. As the industry continues to operate in increasingly challenging environments, the importance of routine maintenance and inspection becomes even more paramount. It’s through these proactive measures that the industry can guarantee safety, maintain productivity, and uphold environmental standards, ultimately contributing to its long-term sustainability and profitability.

Reviews

There are no reviews yet.