Description

Introduction

Pipeline pigging is a crucial process in the maintenance and cleaning of pipelines, ensuring the safe and efficient operation of various industries. In this article, we will explore the skeletal pipe-cleaning pigs, including their types, features, accessories, and the pipeline pigging process. Let’s dive in!

Definition and Purpose of Skeletal Pipe Cleaning Pigs

Pipe pigging involves the use of a specially designed device called a “pig” that is inserted into the pipe for cleaning, inspection and maintenance. These pigs pass through the pipe to remove debris, sediment, and other unwanted materials while checking the integrity of the pipe.

Origin and Meaning of the Term “Pig”

The term “pig” used in pipeline pigging has an interesting origin. It is believed to have come from the squealing sound the early pig models made while passing through the pipelines. The noise resembled the oinking of a pig, and thus the name stuck.

Types of Skeletal Pipe Cleaning Pigs

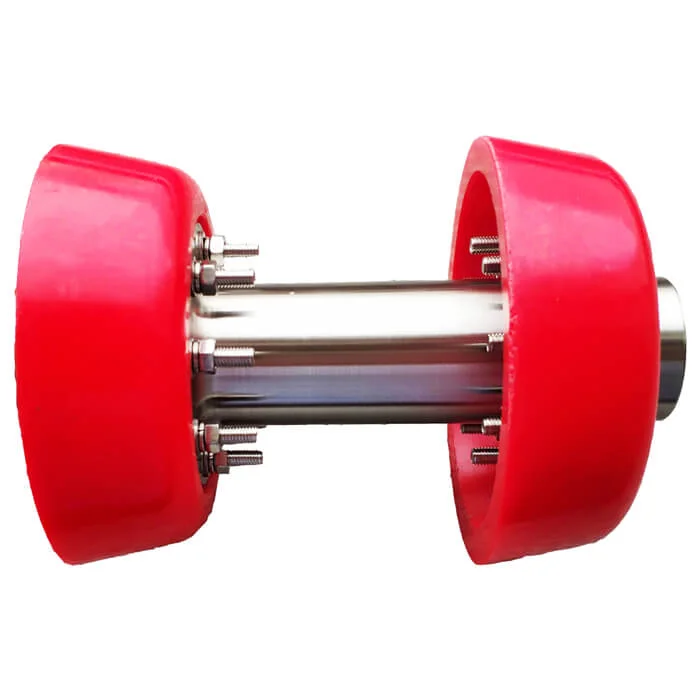

Pipe cleaners come in a variety of forms to meet different pipe cleaning and maintenance needs. There are two main types of skeletal pigs and building materials. The skeletal pig design has an open frame that allows for efficient cleaning and inspection. They can be further divided into two categories:

Skeletal pigs with discs: These pigs are equipped with disc attachments that enhance their cleaning capabilities by scraping and removing debris from pipe walls.

Skeletal pigs with cups: These pigs use cup-shaped attachments to form a tight seal with the pipe wall, effectively removing sediment and contaminants.

Skeleton Materials

Skeletal pigs are commonly constructed using a variety of materials, depending on the specific requirements of the pipeline. Some common materials include:

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel is a popular choice for skeletal pigs.

- Carbon Steel: Carbon steel offers excellent durability and is often used in demanding pipeline applications.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a thermoplastic known for its toughness and impact resistance, making it suitable for pig construction.

- Other Materials upon Request: Manufacturers can provide pigs made from alternative materials based on specific customer requests and pipeline conditions.

Features of Skeletal Pipe Cleaning Pigs

Pipeline pigs come with several features that make them highly effective in pipeline maintenance. Let’s take a look at some key features:

High Flexibility

Skeletal pipe cleaning pigs are designed to navigate through pipelines with bends and curves, ensuring comprehensive cleaning and inspection.

More Resistance and Durability

Because of robust construction, these pigs can withstand harsh conditions within pipelines, including high pressures and abrasive materials.

Longer Operational Lifespan

The durability of skeletal pigs allows them to be used repeatedly, providing extended service life and cost-effective maintenance solutions.

Good Sealing Properties

Pigs equipped with cups or sealing materials ensure a secure fit against the pipeline walls, preventing leakage and optimizing cleaning efficiency.

Bi-directional Operation Capability

Skeletal pigs can travel in both directions within the pipeline, allowing for thorough cleaning and inspection in both upstream and downstream directions.

Main Accessories of Skeletal Pipe Cleaning Pigs

In order to improve the performance of the pipe pig, a variety of accessories are available. Let’s explore the main accessories commonly used in conjunction with skeletal pipe-cleaning pigs.

Cups

The cup is an integral part of the pig and provides sealing and cleaning capabilities. They are available in different materials, such as rubber, polyurethane, and fluororubber, providing varying degrees of sealing performance and limitations.

Discs

Discs serve as guiding and supporting elements in skeletal pigs. They are typically made of polyurethane or other wear-resistant materials and improve cleaning efficiency by scraping debris from pipe walls.

Brushes

Brushes are used to remove stubborn sediments and contaminants from pipe walls. They are usually made of nylon or steel bristles, depending on the level of cleaning required and the sensitivity of the pipe to scratches.

Gauging Plates

Gauging plates help determine the inside diameter of the pipe. They attach to the pig and can provide valuable information about the condition of the pipe, such as any deformation or narrowing that may require further inspection or maintenance.

Magnets

Magnets are implanted in pigs to attract and collect iron particles, such as rust and metal shavings. By trapping these particles, the magnet prevents them from causing damage or clogging downstream equipment.

Tracking Devices

Tracking devices, such as radio frequency identification (RFID) tags or transmitters, can be attached to the pig. These devices accurately track and monitor the position and progress of the pig in the pipeline, ensuring efficient and accurate cleaning and inspection.

Pipeline Pigging Process

The pipeline pigging process includes several steps to ensure thorough cleaning and inspection. The following is an overview of the typical pipeline pigging process:

Prepare the pipe: Isolate the pipe and close the appropriate valve to create the pig section. Set up inlet and outlet connections to enable the pig to enter and leave the pipe.

Pig insertion: The pig is fitted with the necessary accessories for cleaning and inspection and inserted into the pipe through the inlet connection. Use compressed air or water to feed the pig into the pipe.

Pig propulsion: Compressed air, water, or the flowing product itself pushes the pig through the pipe. The pig’s design allows it to move smoothly through bends, obstacles and diameter changes.

Cleaning and inspection: As the pig moves through the pipe, it scrapes, brushes, or cups the pipe walls to remove debris and contaminants. At the same time, it checks the integrity of the pipeline and detects any anomalies or defects.

Pig recovery: Once the pig reaches the desired location or the end of the pipe, the pig is used for recovery. The receiver captures the pig and the line is ready for the next pigging operation.

Inspection and maintenance: After recovery, the pig is inspected to assess the condition of the pipe and identify any potential problems. Based on the results of the survey, maintenance and repair activities can be carried out to ensure optimal performance of the pipeline.

Recording and analysis: Data collected during the pigging process, including inspection results and any anomalies found, are recorded and analyzed. This information can guide further operations, such as scheduling future pigging operations or planning maintenance activities.

Conclusion

Skeletal pipe-cleaning pigs play a vital role in maintaining pipe integrity and efficiency. With their open frame, flexibility and wide range of accessories, they offer effective cleaning, inspection and maintenance solutions. By integrating advanced features and accessories, pipeline operators can optimize the pigging process and ensure safe and reliable pipeline operation for years to come.

Reviews

There are no reviews yet.