Description

I. Introduction of Retractable Injection Quill

A Retractable Injection Quill, as the name suggests, is a device designed to facilitate the injection of chemicals into a process stream while being capable of being retracted or inserted even when the system is under pressure. Used primarily in industrial settings, these quills serve as a crucial element in various chemical treatment applications, particularly where a shutdown of the pressurized line is not feasible or practical. Retractable injection quills are ingeniously designed to enhance chemical dispersion and improve overall system efficacy. They play a pivotal role in ensuring that corrosive chemicals can be safely introduced into a pipeline without causing damage to the pipe or threaded port at the injection point. This is made possible by injecting the chemical into the center stream of the pipe, leveraging the natural turbulence and higher pipe velocity to achieve a homogenous chemical mix. Over the years, retractable injection quills have evolved to offer more advantages, including versatility in size and material options, resistance to high chloride and other chemically aggressive process flows, and the ability to withstand severe conditions such as longer insertion lengths and higher pressures.

II. The Importance of Retractable Injection Quill

Retractable Injection Quills are indispensable in many industries, particularly those involving chemical processing, water treatment, power generation, and oil and gas production. They serve a crucial function in the safe and efficient delivery of chemicals into a variety of systems under pressure.

One of the most significant problems that retractable quills solve is the need for continuous operation. In many industrial settings, it’s not practical or even possible to shut down the entire system to insert or remove an injection quill. With a retractable design, operators can adjust the quill as needed without disturbing the overall process, saving valuable time and resources.

Furthermore, retractable injection quills significantly improve chemical dispersion within the system. By injecting chemicals directly into the center stream of the pipe, they leverage the naturally occurring turbulence and higher velocities to create a more homogenous chemical mix. This not only enhances the efficiency of the chemical process but also minimizes potential damage to the pipeline from corrosive chemicals.

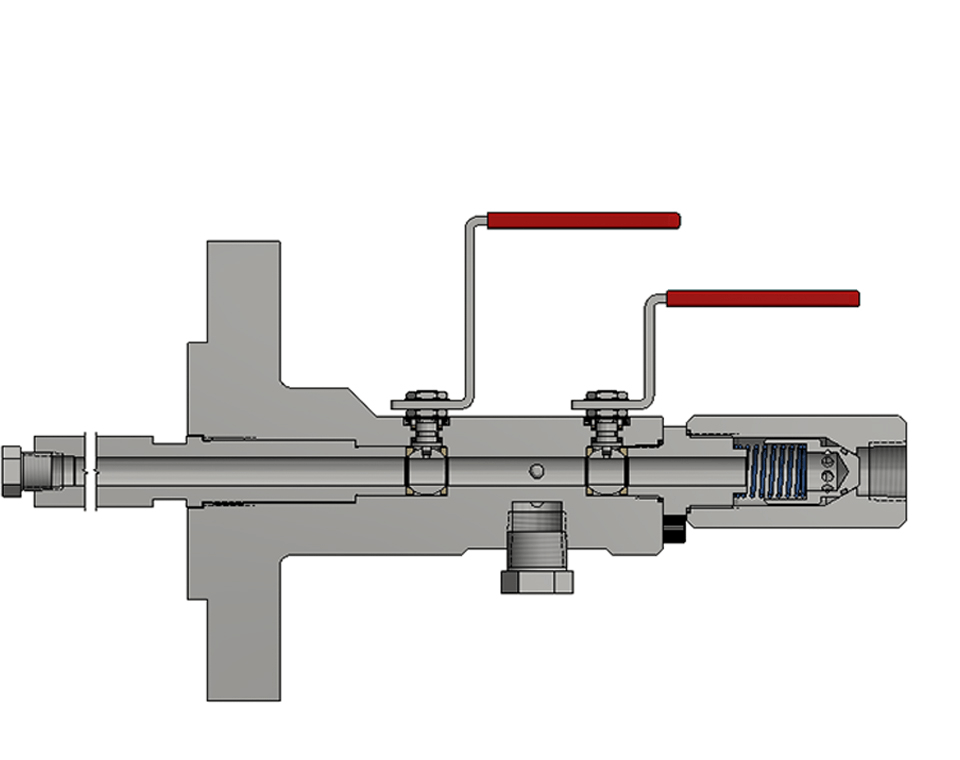

Name | High-Pressure Pipeline Chemical Injection Quills Sampling System | |

| Material | Stainless Steel 304、Stainless Steel 316、DSS F51、Carbon Steel A105N、Inconel 625 | |

| Operating Temperature | -20±120℃ | |

| Feature | 1. Easy Operating | |

| 2. High Accuracy, Long Life | ||

| 3. High Efficiency, Low cost | ||

| Payment | TT/LC | |

| Advantage | First, they are lightweight and flexible. | |

| Secondly, nice injection efficiency. | ||

| Lastly, accurate location tracking |

Retractable Injection Quills are indispensable in many industries, particularly those involving chemical processing, water treatment, power generation, and oil and gas production. They serve a crucial function in the safe and efficient delivery of chemicals into a variety of systems under pressure.

One of the most significant problems that retractable quills solve is the need for continuous operation. In many industrial settings, it’s not practical or even possible to shut down the entire system to insert or remove an injection quill. With a retractable design, operators can adjust the quill as needed without disturbing the overall process, saving valuable time and resources.

Furthermore, retractable injection quills significantly improve chemical dispersion within the system. By injecting chemicals directly into the center stream of the pipe, they leverage the naturally occurring turbulence and higher velocities to create a more homogenous chemical mix. This not only enhances the efficiency of the chemical process but also minimizes potential damage to the pipeline from corrosive chemicals.

III. Working Mechanism of Retractable Injection Quill

III. Working Mechanism of Retractable Injection Quill

Retractable injection quills are designed to deliver chemicals directly into the center of the process stream to enhance chemical dispersion, which ultimately improves the overall effectiveness of the treatment process.

- Retractable Feature: The quill assembly is attached to a process line via a corporation stop or a similar type of valve. This valve allows the quill to be inserted or retracted while the system is still under pressure.

- Injection: Once positioned inside the process line, the quill delivers the chemical directly into the process flow. The tip of the quill is designed to disperse the chemical evenly across the flow, which improves the reaction efficiency.

- Retraction: If the quill needs to be cleaned, inspected, or replaced, it can be retracted without shutting down the process line. The valve seals off the process line, preventing any leakage.

- Replacement or Maintenance: After the quill has been retracted, it can be serviced or replaced. Once maintenance is complete, the quill can be reinserted back into the process line.

Benefits of Being Able to Insert or Remove Quills While the System Remains Under Pressure

The ability to insert or remove quills while the system is under pressure offers several key benefits:

- Minimal Disruption: This feature allows for maintenance or replacement of the quill without having to shut down the entire system. This can result in a significant reduction in downtime, increasing overall system productivity.

- Safety: The design of retractable injection quills ensures that chemicals are safely contained during maintenance. This reduces the risk of chemical exposure to workers and prevents chemical spillage, making the workplace safer.

- Cost Efficiency: By reducing system downtime and improving chemical reaction efficiency, retractable injection quills can significantly improve the cost-efficiency of the chemical treatment process.

- Flexibility: The retractable feature offers flexibility in handling different process conditions. For example, the quill can be easily retracted during periods of high flow or turbulence, preventing damage to the quill and ensuring a consistent chemical treatment.

IV. Material and Size Options

- Different materials and sizes are available and can be customized.

Retractable injection quills are available in a wide range of materials and sizes to meet varying needs and requirements. Depending on the specific application and conditions of use, different materials may be more suitable. For instance, options may include materials like Inconel for its durability and resistance to corrosion, or stainless steel for its cost-effectiveness and resistance to a variety of chemicals. Each material has its unique properties, making it more or less suitable for specific applications.

In addition to material selection, the size of the quill can also play a crucial role in its performance. Sizes might range from smaller quills for lower flow rates or narrow process lines, to larger quills for higher flow rates or wider process lines. The right size ensures efficient chemical dispersion and reduces the risk of damage to the quill or process line.

VII. Conclusion

Retractable injection quills have emerged as a pivotal component in industries that rely heavily on the safe and efficient delivery of chemicals into pressurized systems. Their ingenious design, which allows them to be inserted or retracted while the system remains pressurized, solves the problem of continuous operation, thereby reducing system downtime and improving overall productivity.

These quills enhance chemical dispersion by injecting chemicals directly into the center of the process stream, leveraging the natural turbulence and velocities to achieve a more homogenous mix. The result is a significant improvement in the efficiency of the chemical treatment process while minimizing potential damage to the pipeline from corrosive chemicals.

III. Working Mechanism of Retractable Injection Quill

III. Working Mechanism of Retractable Injection Quill

Reviews

There are no reviews yet.