Description

Introduction

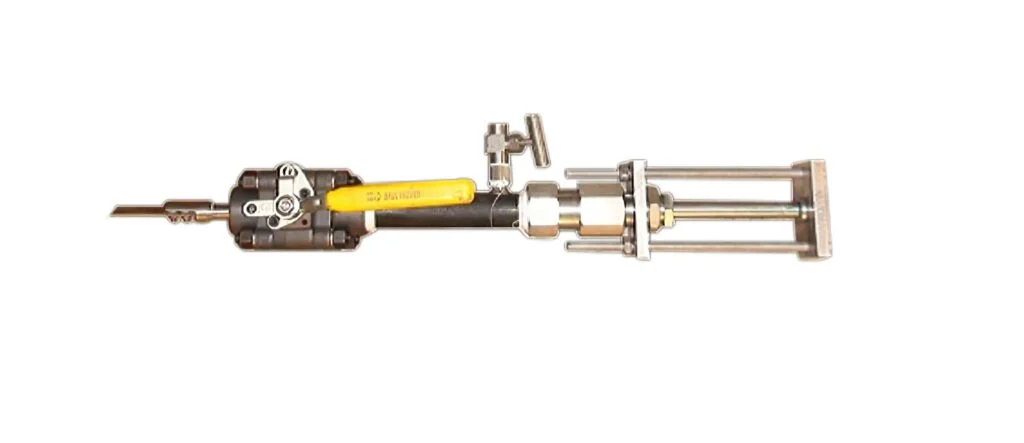

The EMT-RCC Retractable Corrosion Coupon System can operate at pressures up to 1500 Psi (10.3 MPa) and temperatures up to 500℉/260℃. During operation, the installation depth of the corrosion coupon probe can be adjusted according to the diameter and wall thickness of the pipeline. The standard corrosion coupon system lengths include 24 inches, 30 inches, 36 inches, 42 inches, and 48 inches, suitable for pipelines of different diameters. The end of the corrosion coupon system can hold an insulated strip-type corrosion coupon. The corrosion coupon system is provided as a whole, including a probe rod, ball valve, corrosion coupon, and adjustable safety clamp kit. The use of the safety clamp is recommended when the pipeline pressure is below 1500 psi and the temperature is below 500℉.

Coupon Specifications

The standard configuration for the retractable corrosion coupon system is a 3″ strip coupon, with dimensions (Length x Width x Thickness) of 3″ x 1/2″ x 1/16″ (7.6 cm x 1.3 cm x 0.16 cm). It has two installation holes and a surface area of 3.4 in² (21.9 cm²).

- Pressure Rating: 1500 PSI (10.3 MPa)

- Mounting: 1″ Full Port Valve Minimum

- Temperature Rating: +500º F/+260º C

- High-Temperature Option Available (1000º F)

- Material: 316 SS

- Meets NACE MR0175 and MR0103

- Seal Material: Teflon

Benefits of Retractable Corrosion Coupons

The Retractable Corrosion Coupons are available in various lengths to cater to different needs, including 18, 24, 30, and 36 inches. These coupons are designed to withstand high pressure and temperature conditions, with a pressure rating of up to 1500 PSI or 10.3 MPa and a temperature rating of up to 500° F or 260°C. Constructed from 316 stainless steel, they offer excellent durability and resistance to corrosion. They also meet the strict requirements of NACE MR0175 and MR0103 which guarantees their quality and dependability in a wide range of industrial settings.

Applications of Retractable Corrosion Coupons

The Retractable Corrosion Coupons serve various applications by providing a retractable means of coupon monitoring in processes. With a minimum requirement of a 1″ full-port valve for mounting, these coupons offer flexibility in installation. The design of the coupon holder is also noteworthy; its single tongue allows for the use of either one or two-strip coupons. These can be insulated or uninsulated, depending on the specific requirements of the process. This design versatility maximizes the utility of the Retractable Corrosion Coupons in diverse industrial settings.

Additionally, the specifications of the corrosion coupons can be customized according to user requirements.

How to Install Retractable Corrosion Coupons

(1) Preparation Before Installation

Drill a hole with a diameter of φ27~30 mm at the predetermined installation position on the pipe, and clean up any burrs after machining. Remove rust from the surface of the area to be welded.

(2) The Welded Base Separation

Unscrew the welded base from the corrosion coupon system, detaching it at the point where the welded base meets the valve. Fix the valve body with a wrench, and remove the welded base with another wrench.

(3) Welding the Welded Base

Weld the welded base to the pipe after aligning it with the drilled hole (perpendicular to the pipe center and wall and concentric with the hole).

(4) Calculate the Installation Distance L.

Use a probing rod or directly measure the maximum distance between the upper surface of the welded base and the inner surface of the pipe after welding the base. Keep the probe rod perpendicular to the pipe center and the inner surface of the pipe wall when measuring.

After measuring, calculate the positioning distance L using the formula L = L0 – 10 mm.

Make a note of this for future reference (it will be required for future coupon installation and maintenance).

(5) Adjust the Safety Clamp Distance

Adjust the locking nut of the lower safety clamp. According to the 5~7mm distance requirement, fix the two bolts to the lower safety clamp. By adjusting the adjustment nuts on both sides of the upper safety clamp, adjust the distance between the two safety clamps.

(6) Install the Sealing Material

Remove any leftover sealing material from the valve threads and the welded base threads. Rewrap the sealing material around the valve’s external threads.

(7) Install the Corrosion Coupon System

Connect the corrosion coupon system to the welded base (two people are required). After ensuring that the threads are properly aligned and screwed in, rotate the corrosion coupon system until it cannot move any further, and then tighten the valve with a wrench.

(8) Adjust the corrosion coupon to its final installation location.

The positioning distance L should be used to set the distance between the upper safety clamp and the flat surface of the welded base. If the distance between the upper safety clamp and the flat surface of the welded base is greater than L0, the upper safety clamp should be moved downward to match the L distance. This is the shortest distance, i.e., the deepest penetration of the corrosion coupon into the pipe. This guarantees that, once the coupon system is mounted on the base, the lower end of the corrosion coupon is as close to the bottom of the pipeline as possible while still keeping a safe distance.

(9) Adjust the Corrosion Coupon’s Direction

Adjust the corrosion coupon indicator surface (Figure 3) at the top of the coupon support rod with a wrench to ensure that the indicator surface faces the direction of the medium flow inside the pipe. (At this time, the corrosion coupon’s breadth direction is parallel to the pipe direction.)

Conclusion

In conclusion, the EMT-RCC Retractable Corrosion Coupon System stands as an exceptional solution to monitor and manage corrosion in various industrial processes. Its unique design, which is available in different lengths and withstands high pressures and temperatures, makes it a versatile tool for different pipeline diameters. The system, made from resilient 316 stainless steel and meeting key industry standards like NACE MR0175 and MR0103, guarantees excellent durability and corrosion resistance.

Moreover, the system’s design allows for the use of either one or two strip coupons, which can be insulated or uninsulated, providing considerable flexibility in application. The installation process, though detailed, is straightforward and can be adapted based on specific pipeline characteristics. These features, along with the opportunity for customization, make Retractable Corrosion Coupons a valuable asset in a wide range of industries.

By implementing such systems, companies can effectively monitor corrosion, extend the lifespan of their infrastructure, and ultimately save on potential repair or replacement costs. As industries continue to seek efficient and reliable ways to combat the pervasive problem of corrosion, the use of the EMT-RCC Retractable Corrosion Coupon System will undoubtedly become more widespread.

Reviews

There are no reviews yet.