Description

Introduction

Quick Opening Closure (QOC) is a device specifically designed for efficient and safe closing of various industrial containers and equipment. With its innovative design and functionality, QOC offers many advantages over standard blind flanges, making it an indispensable part of many industries. In this article, we will explore the definition, purpose, and benefits of quick-opening closures, as well as the expertise required for their design and manufacture.

Definition and Purpose of Quick Opening Closure

A Quick Opening Closure (QOC) is a mechanically closed system. QOC is used to seal and open access points for ships and equipment operating under pressure. Its main purpose is to provide fast and secure access for maintenance, inspection, cleaning and other operations, minimizing downtime and ensuring operational efficiency.

Advantages of Standard Blind Flanges

Quick Opening Closures offer several key advantages. First, they can be turned on and off quickly, saving time and labor during maintenance. Second, the quality control center provides a tight and reliable seal that minimizes the risk of leakage or contamination. In addition, they enhance safety by combining features such as pressure warning devices and mechanical safety interlocks.

Expertise in Designing and Manufacturing QOC

Designing and manufacturing fast opening and closing closures requires specialized knowledge and expertise. Companies like EMT have extensive experience in this area, offering customized solutions that meet industry standards and customer specifications. Their expertise includes the selection of appropriate materials, compliance with regulatory requirements, and the integration of safety features.

Types of Quick Opening Closures

Seg-Band Type (Segmented Band Locking Type)

Description and Functionality

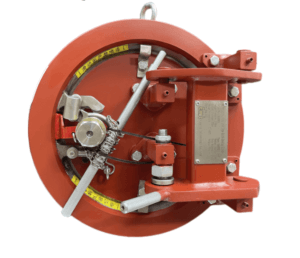

The Seg-Band Type Quick Opening Closure features a segmented band locking mechanism, which ensures a secure and uniform distribution of the closure force. This design allows for easy and efficient operation while maintaining a reliable seal.

Compliance with ASME Sec VIII Div. 1 UG-35 Requirements

Seg-Band Type Closures comply with the ASME Section VIII Division 1 UG-35 requirements, ensuring their suitability for a wide range of applications in various industries.

Inclusion of a Pressure Warning Device and Mechanical Safety Interlock

To enhance safety, Seg-Band Type Closures often include pressure warning devices that provide visual or audible alerts when pressure is present. Mechanical safety interlocks prevent accidental opening of the closure while the vessel is under pressure.

Clamp Type (Double Yoke Type)

Description and Functionality

The Clamp Type Quick Opening Closure utilizes a double yoke design to evenly distribute closure force. This ensures a tight seal and allows for quick and effortless opening and closing operations.

Compliance with ASME Sec VIII Div. 1 UG-35 Requirements

Clamp Type Closures adhere to the stringent requirements of ASME Section VIII Division 1 UG-35, ensuring their reliability and suitability for diverse industrial applications.

Inclusion of a Pressure Warning Device and Mechanical Safety Interlock

Similar to Seg-Band Type Closures, Clamp Type Closures are equipped with pressure warning devices and mechanical safety interlocks to prevent accidents and maintain a high level of safety.

Swing Bolt Type Closures

Description and Functionality

Swing Bolt Type Closures utilize swing bolts to secure the closure door. This design offers simplicity and ease of operation while maintaining a reliable seal.

Features and Benefits

Swing Bolt Type Closures are known for their robust construction and durability. They are suitable for applications where frequent access is required, offering quick and secure closure in various industrial environments.

Materials and Accessories

ASME-Approved Materials Used for Manufacturing QOC

Manufacturers of Quick Opening Closures adhere to stringent standards set by the American Society of Mechanical Engineers (ASME). The choice of material depends on the specific application, operating conditions, and compatibility requirements. This flexibility ensures that QOCs can be customized to meet the unique needs of different industries.

Flexibility to Accommodate Customer Specifications

Quick Opening Closures can be tailored to meet specific customer requirements. Manufacturers like Sungov have the expertise to incorporate customer-specified materials, finishes, and coatings. This flexibility allows for seamless integration with existing equipment and ensures compatibility with a wide range of industrial processes.

Additional Accessories Available for QOC

Sight Glasses, Nozzles, Drains, Gauges, Sampling Ports

Quick Opening Closures can be equipped with additional accessories to enhance their functionality. These accessories include sight glasses for visual inspection, nozzles for fluid transfer, drains for effective drainage, gauges for pressure monitoring, and sampling ports for obtaining samples during operation. By incorporating these accessories, QOCs become more versatile and adaptable to various process requirements.

Safety Interlocks for Enhanced Security

Safety is a paramount concern in industrial operations. Quick Opening Closures often feature safety interlocks, which provide an added layer of security. These interlocks ensure that the closure cannot be opened unless specific safety conditions are met, such as relieving pressure or activating a lockout/tagout system. This feature prevents accidental or unauthorized access, reducing the risk of accidents or injuries.

Design and Application Flexibility

Horizontal and Vertical Application Suitability

Quick Opening Closures are designed to be versatile and suitable for both horizontal and vertical applications. Whether installed on pipelines, pressure vessels, or storage tanks, QOCs can effectively seal access points in any orientation, allowing for seamless integration into various industrial setups.

Connection Types and Design Variations

Full and Reduced Access

Quick Opening Closures are available in full and reduced access designs. Full access closures allow complete access to the vessel or equipment, facilitating thorough inspection and maintenance. Reduced access closures provide limited access, ideal for applications where partial access is sufficient, saving time and reducing costs.

Mitered Designs for Inclined or Declined Vessels

Mitered designs are available for inclined or declined vessels where the closure door and hub are angled to match the vessel’s orientation. This design variation ensures a proper fit and effective sealing even in non-horizontal applications.

Features and Safety Measures

SEG-LOK System for Quick and Easy Operation

Quick Opening Closures often employ the SEG-LOK system, a specialized mechanism that enables quick and easy opening and closing operations. The SEG-LOK system ensures a secure and reliable seal while providing efficient access to the enclosed equipment.

Segmental Locking Mechanism and Secondary Safety Latch

To enhance safety and prevent accidental opening, Quick Opening Closures feature a segmental locking mechanism. This mechanism ensures uniform distribution of closure force, maintaining a tight seal. Additionally, a secondary safety latch provides an extra layer of security, further minimizing the risk of unintentional opening.

Self-Energizing Seals for Optimal Pressure and Temperature Resistance

Quick Opening Closures utilize self-energizing seals, which provide optimal sealing performance even under high-pressure and high-temperature conditions. These seals adapt to changes in internal pressure, ensuring a reliable and leak-free seal throughout the operational lifespan of the closure.

Fully Supported Adjustable Door with Davit Arm and Lifting Mechanism (for Vertical Installations)

In vertical installations, Quick Opening Closures are designed with a fully supported adjustable door. This feature ensures the door remains stable and properly aligned, even when subjected to vertical forces. To facilitate the opening and closing of the vertical closure, a davit arm, and lifting mechanism are incorporated, providing ease of operation and reducing the physical effort required.

Stainless Steel Nameplate with Full Instructions Attached to Each Closure Hub

Quick Opening Closures come equipped with a stainless steel nameplate affixed to each closure hub. The nameplate displays important information such as operating instructions, safety precautions, and maintenance guidelines. This ensures that operators have easy access to essential information, promoting safe and efficient usage of the closures.

Applications and Use Cases

End Closures for Pig Launchers and Receivers (Scrapper Trap Doors)

Quick Opening Closures are widely used in the oil and gas industry. These closures allow easy insertion and removal of the cleaning device, the pig, in the piping system. The fast opening and secure sealing of the closure enables efficient maintenance and inspection of the pipeline, ensuring optimal operating performance.

Pressure Vessel End Closures (Filter Vessel Quick Opening Closures)

In pressure vessel applications, Quick Opening Closures serve as reliable end closures. They allow quick access to the inside of the container for inspection, cleaning or replacement of filter elements. By minimizing downtime and promoting effective maintenance, these closures contribute to the uninterrupted operation of filtration systems in different industries.

Blowdown Lines End Closures

Quick Opening Closures are also used as end closure valves for blowdown lines to safely release excess pressure from containers or pipes. These closures enable quick, controlled opening and closing of blowdown lines, ensuring safe and efficient discharge of pressurized fluids.

Conclusion

In conclusion, Quick Opening Closures (QOCs) offer numerous advantages over standard flanges, making them indispensable in a wide range of industrial applications. Its quick opening and closing capability, reliable sealing, and combined safety features improve operational efficiency and ensure worker safety. qos offers design flexibility due to its ability to adapt to customer specifications and a wide range of materials. Manufacturers like EMT are committed to providing high quality, asme compliant quality standards that prioritize safety, efficiency and customer satisfaction. By investing in fast opening closures, the industry can optimize processes, reduce downtime, and increase productivity and reliability.

Reviews

There are no reviews yet.