Description

Introduction

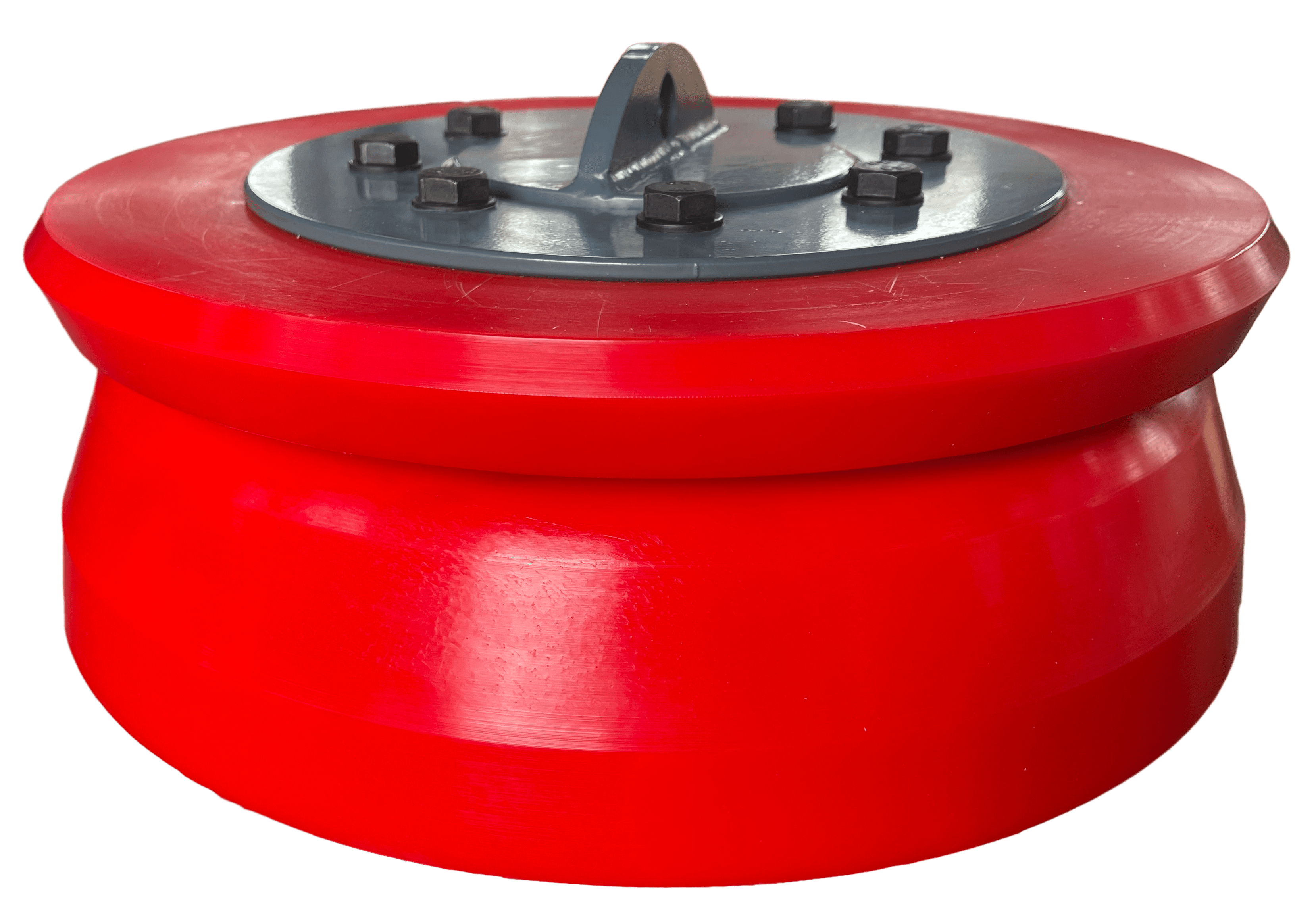

A piping pig with polyurethane brushes is a specialized tool designed for the maintenance and cleaning of pipelines in the oil, gas, water industries, and other industries. The pig is inserted into the pipeline and pushed along by the pressure of the pipeline. As it travels, the polyurethane brushes on the pig make contact with the inner walls of the pipeline, effectively removing built-up debris, scale, and other contaminants. This ensures that the pipeline remains in optimal condition for the efficient and safe transport of fluids. Piping pigs can be fitted with various types of brushes, including steel brushes and polyurethane brushes, to remove debris, scale, and other contaminants from the inner walls of the pipeline.

Advantages

- Durability: Polyurethane is a highly durable material that can withstand the abrasive conditions inside a pipeline, making these types of cleaning pigs long-lasting.

- Efficiency: The polyurethane brushes are effective at removing various types of debris, from rust and scale to more stubborn deposits, ensuring a thorough cleaning.

- Chemical Resistance: Polyurethane is resistant to many chemicals, making it suitable for pipelines that carry a variety of substances, including oil, gas, and certain chemicals.

- Flexibility: Polyurethane brushes can adapt to the contours of the pipeline, ensuring a more effective cleaning process that reaches all areas of the interior surface.

- Reduced Wear and Tear: The use of polyurethane brushes can minimize the wear and tear on pipelines, extending their operational lifespan.

- Safety: Effective cleaning reduces the risk of blockages and build-up that could lead to operational issues or even accidents, making the pipeline safer to operate.

- Ease of Use: These cleaning pigs can be easily integrated into existing pipeline systems without the need for extensive modifications.

- Environmental Benefits: By maintaining the efficiency of the pipeline, these cleaning pigs can also contribute to reduced energy consumption and lower emissions.

- Versatility: Suitable for use in various types of pipelines, including those used in the oil, gas, and water industries.

Working Principle

The working principle of a piping pig is relatively straightforward. A piping pig is a solid or semi-solid device that is inserted into a pipeline for the purpose of cleaning, inspecting, or separating different products within the pipeline. Here’s how it generally works:

- Insertion: The piping pig is inserted into a “pig launcher,” which is a starting point connected to the pipeline. The launcher is then sealed.

- Propulsion: Once the launcher is sealed, the pressure of the fluid (oil, gas, water, etc.) behind the pig starts to build up. This pressure propels the pig forward into the pipeline.

- Travel: As the piping pig travels through the pipeline, it fits snugly against the inner walls. This ensures that it scrapes off or pushes any debris, scale, or other contaminants that may have built up on the pipeline walls.

- Cleaning Mechanism: Depending on the type of pig used, various cleaning mechanisms may be involved. For example, a cleaning pig with polyurethane brushes will use these brushes to scrub the inner walls of the pipeline as it moves along.

- Detection and Inspection: Some pigs are equipped with sensors and other instrumentation to detect issues like cracks, leaks, or corrosion in the pipeline. These are known as “smart pigs.”

- Arrival at Receiver: Eventually, the pig arrives at a “pig receiver” or “pig trap” at the other end of the pipeline segment being cleaned or inspected. This is an area where the pig can be safely removed from the pipeline.

- Removal and Analysis: Once the pig is removed, any debris it has collected can be analyzed to determine the condition of the pipeline. If the pig is a “smart pig,” the data collected can be downloaded and analyzed to assess the pipeline’s integrity.

Our Service

1. There are many kinds of signallers of different types to meet different requirements.2. We offer samples to demonstrate our commitment to quality and service.3. The fastest feedback!4. The fastest delivery time.5. 24 hours,7 days online.

Conclusion

In summary, piping pigs equipped with polyurethane brushes serve as an invaluable tool for the maintenance and cleaning of pipelines across multiple industries, including oil, gas, and water treatment. Their design and material advantages, ranging from durability and efficiency to chemical resistance and flexibility, make them an essential component for ensuring the operational integrity and safety of pipeline systems. Our company, with its rich history since 1993, remains committed to delivering high-quality, customized solutions for corrosion monitoring and pipeline cleaning. Our diverse range of products and exceptional services, including fast feedback and delivery, demonstrate our unwavering commitment to meeting the unique needs of each project. Investing in such advanced pipeline maintenance technology not only enhances operational efficiency but also contributes to environmental sustainability.

Reviews

There are no reviews yet.