Description

Pig Signaller Manufacturer

Shenyang Emt Piping Technology Co., Ltd. proudly stands as a leading manufacturer of Pig Signallers. Our product, a sturdy, non-invasive magnetic pig signaller – is expertly designed to detect, signal, and log the passage of magnetic pigs at key locations in both onshore and offshore pipelines.

This advanced device ensures real-time event signaling. Each event is immediately indicated through a highly visible 2.7″ graphical display. Complementing this is an array of high-brightness LEDs strategically positioned around the display’s perimeter, enhancing visibility and ensuring immediate recognition of pig passage events.

Our commitment to quality and efficiency is reflected in this cutting-edge pig signaller, which plays a pivotal role in monitoring and managing pipeline pigging operations. We continue to strive for technological excellence, aiming to provide the best solutions for pipeline technology needs.

Brand: EMT Pigging |

Plug Type: Bidirectional/Unidirectional |

Insert Depth: 21 mm |

Flange Material: Carbon Steel / Stainless Steel |

Flange Class: 300# |

Operating Temperature: -20 ℃ ~ +120 ℃ |

EMT simplifies and elevates the process of pig detection with its range of intrusive pig signallers:

Our state-of-the-art intrusive pig signallers serve as detector instruments that are strategically mounted on pig launchers and receiver stations. Their primary function is to confirm the launch or arrival of a pig, ensuring effective and efficient pipeline operations. However, their versatility extends beyond these primary locations – our signallers can be installed at any point along a pipeline, and they possess the capability to detect the passage of all types of pipeline pigs.

One of the standout features of our intrusive Pig Signaller is its unique magnetic system designed to prevent blockage due to fluid exchange. This innovative feature effectively eliminates the risk of leakage from the action seal, contributing to the overall safety and reliability of pipeline operations.

Additionally, the signaller’s trigger mechanism has been engineered for enhanced flexibility. This design feature not only simplifies the installation process but also reduces the need for frequent maintenance, leading to lower operational costs.

We are committed to providing you with superior pipeline pigging solutions. If you’re in search of a reputable Pig Signaller Manufacturer, we invite you to get in touch with our team of professionals. They are ready and eager to answer your queries and help you select the product that best meets your specific needs.

Indicator Type | B | C | D |

Manufacturer | EMT Pig Signaller Manufacturer | ||

Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals |

Installing type | 2″welded base, nipple joint. Design pressure up to 3000 psi. | ||

Trigger type | Uni-directional | ||

Insert depth (In pipe) | 13 mm | ||

Plug body length | settled | ||

Insert depth adjustment | 20 mm | ||

Operating temperature | -20~120℃/Meet customer needs | ||

NACE MR 0175 | Yes | ||

Ingress protection | IP65/IP66 | ||

Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | |

Include isolation valve | NO | ||

With bypass valve | NO | ||

With bleed valve | NO | ||

Remove under pressure | Yes | ||

Retriever | Special Retriever | ||

Parameters of Non-intrusive Pig Signaller

1. Applicable temperature: – 40 ~ 85 ℃. The Non-intrusive Pig Signaller can function effectively in temperatures between -40 and 85 degrees Celsius.

2. This device is suitable for use with conveying pipes constructed from any material.

3. The pig is equipped with a permanent magnet, exerting a force between 3000 and 4500 Gauss.

4. The Pig Signaller is applicable in locations with various gases and mediums.

5. Explosion proof: Exd Ⅱ CT6 The device carries an explosion proof rating of Exd II CT6.

6. Protection: IP65.

7. Power supply: 4 No. 7 batteries or 24V DC power supply is selected through jumper cap.

8. The remote signal can be either normally open or normally closed.

9. Contact capacity: not more than 3A.

10. Remote Signal Activation Time: The remote signal has an action time of 3 seconds.

| Name | Non Intrusive Pig Signaller | |

| Material | 304 SS, 316SS, DSS F51, DSS F53, DSS F55, Carbon Steel A105N, and also Inconel 625 | |

| Operating Temperature | -20± 120 ℃ | |

| Feature | Firstly, High wear resistance | |

| Secondly, Good cleaning performance | ||

| At last, Low cost | ||

| Payment | TT/LC | |

| Advantage | Firstly, They are lightweight and flexible. | |

| Secondly, Nice cleaning efficiency. | ||

| At last, Accurate location tracking. |

Advatages of Two Types of the Pig Signaller

As one of the Pig Signaller Manufacturers, Emt provides these two types of connection:

Welded Connection Pig Signaller:

- Strength: The welded connection creates a strong, continuous path between the signaller and the pipeline. This enhances the structural integrity of the signaller, making it more resistant to high pressures and stresses.

- Leakage Prevention: Welded connections are less prone to leaks as there are no mechanical joints or seals that can fail over time.

- Lower Maintenance: Once a welded connection is made, it typically requires less maintenance than a flanged connection due to the absence of bolts or gaskets that can wear out.

- Space-efficient: Welded connections take up less space than flanged connections, which can be beneficial in areas with limited space.

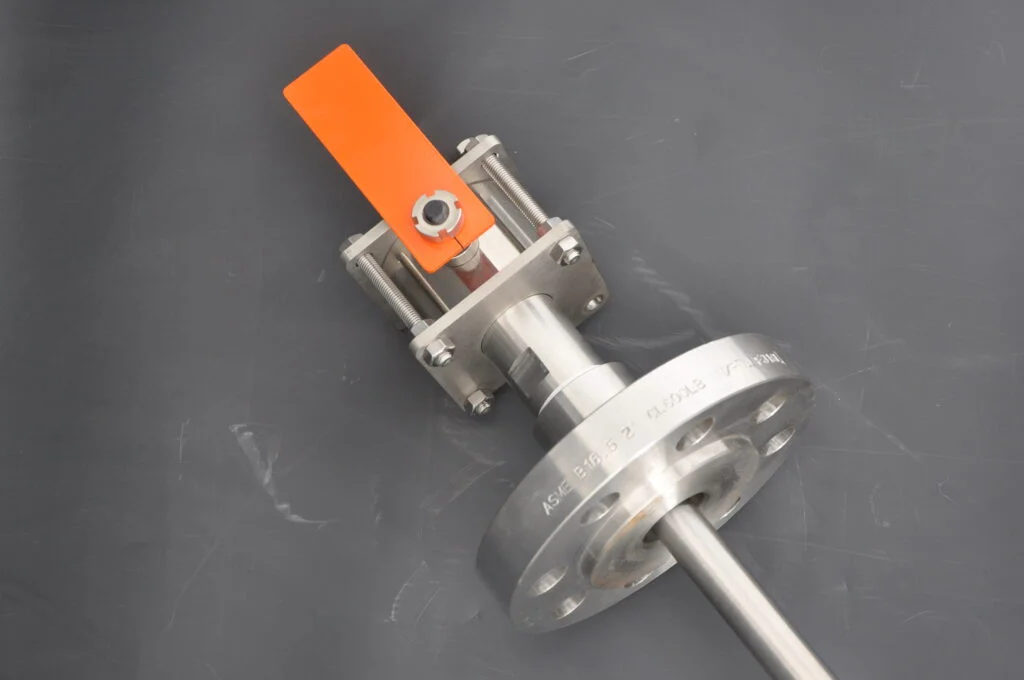

Flange Connection Pig Signaller:

- Ease of Installation and Removal: Flanged connections allow for easy assembly and disassembly of the pig signaller. This makes maintenance, inspection, and replacement processes simpler and quicker.

- Flexibility: Flanges can be designed to connect different types of materials or different pipe sizes, providing more flexibility in pipeline configurations.

- Visual Leak Detection: In case of leaks, they are easier to spot in a flange connection compared to a welded one. This can facilitate quicker repairs and less downtime.

- No Special Skills Required: Unlike welding, which requires specialized skills and equipment, flanged connections can be assembled using basic tools, making them more convenient in certain scenarios.

Our Service-EMT Pig Signaller Manufacturer

Our Commitment

At EMT, a leading Pig Signaller Manufacturer, we place customer satisfaction at the forefront of our ethos. Our diverse selection of top-notch Pig Signallers, tailored to meet a variety of specific needs, stands as a testament to our commitment towards quality and innovation. Contact us to explore the perfect pipeline solution for your requirements.

Quality Assurance

We are confident in the superior quality of our Pig Signallers. To let you experience this excellence firsthand, we offer the opportunity to request sample units. Experience the difference with EMT’s Pig Signallers.

Customer Service

Customer service lies at the heart of our operations as a trusted Pig Signaller Manufacturer. Our dedicated team is always ready to address your queries and concerns promptly and efficiently. Your satisfaction is our priority.

Delivery & Packaging

Understanding the importance of timely delivery in your operations, we ensure swift order fulfillment. Our 24/7 online support ensures that your needs are met at any time of the day or week.

Our Pig Signallers are packaged in sturdy, lightweight CASES that offer multiple benefits:

- CASES are durable and retain their shape without deforming, ensuring that our Pig Signallers reach you in perfect condition.

- By using CASES, we eliminate the need for fumigation, making the shipping process more streamlined and environmentally friendly.

In all our endeavors, we, as a reputable Pig Signaller Manufacturer, are committed to delivering superior products efficiently, with unwavering focus on customer satisfaction. Trust EMT for your pipeline pigging solutions.

Reviews

There are no reviews yet.