Description

I. Introduction

Pig detectors are specialized instruments employed in the pipeline industry, designed to detect and signal the passage of a pig (Pipeline Inspection Gauge) through a pipeline. Pigs are devices introduced into pipelines for a range of maintenance activities, such as cleaning the pipeline, inspecting for potential damage, or segregating different products within the pipeline. The primary function of a pig detector is to confirm the pig’s passage at specific points along the pipeline, thereby ensuring its successful traversal through the system.

The role of pig detectors is crucial for several reasons. Primarily, they enhance safety by enabling operators to ascertain whether the pig has become stuck or lost – a situation that could potentially lead to pipeline blockages or other safety hazards. Furthermore, pig detectors contribute to operational efficiency, as knowing the pig’s location helps operators manage the pigging process more effectively. Lastly, the data provided by pig detectors can aid in planning pipeline maintenance activities by pinpointing the location of detected issues. Thus, pig detectors are an essential tool in the safe and efficient execution of pipeline pigging processes.

II. Understanding Pig Detectors (Various types)

We can manufacture all of these products:

- Pig Detector :

– Flange Connection

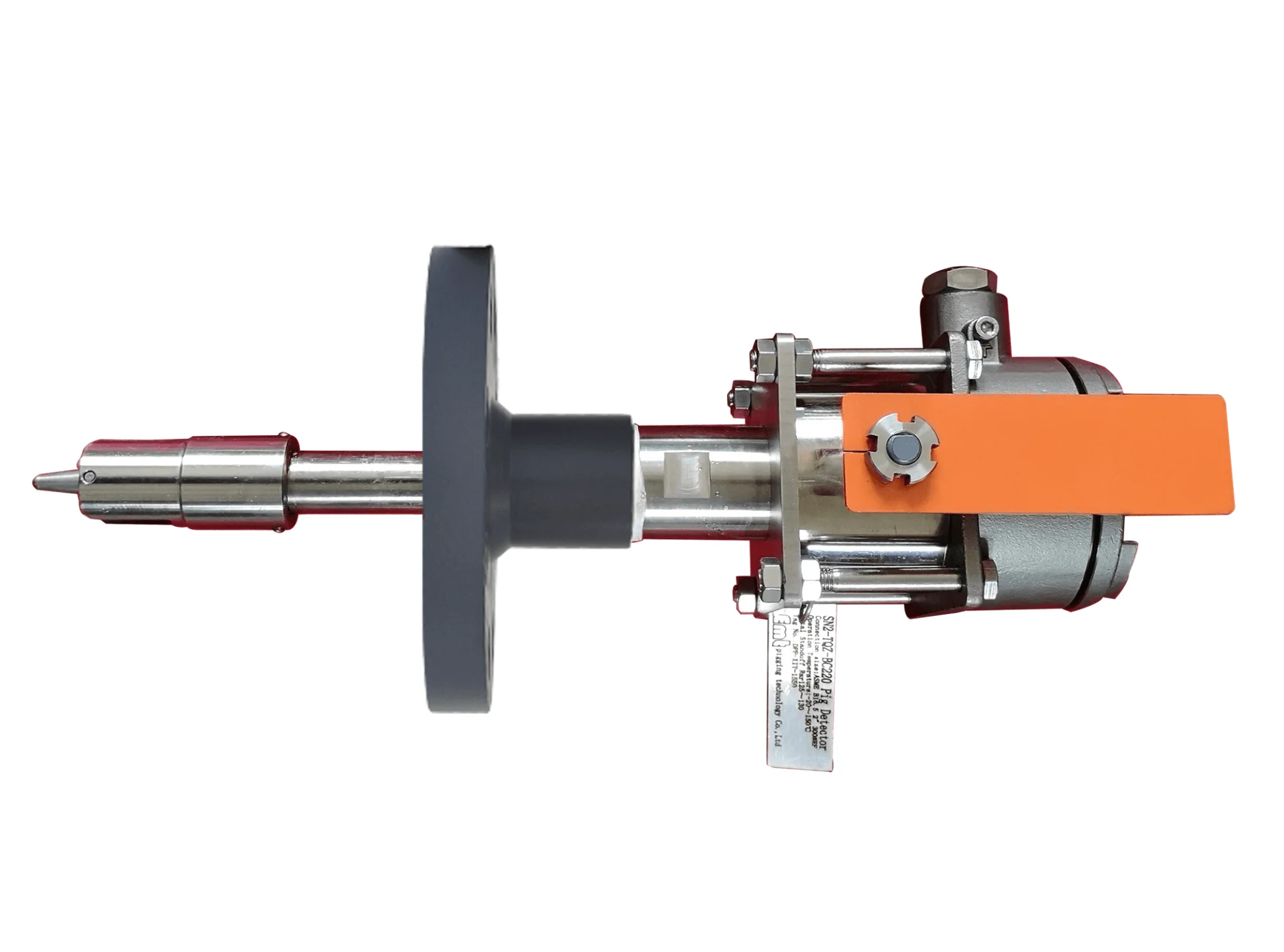

– Flange Connection 20mm Adjustable

– 2” Welded Base

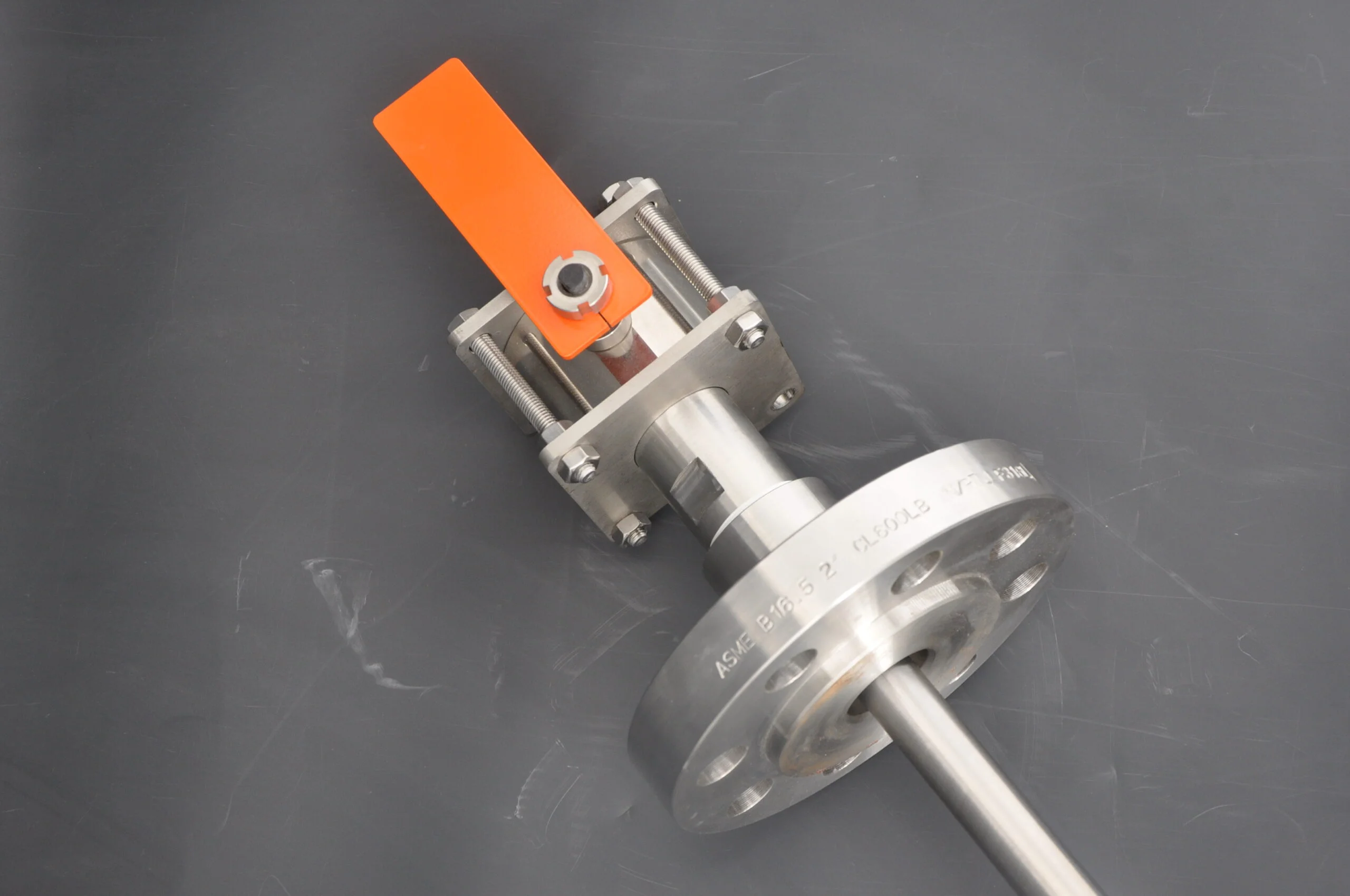

– on Flange Valve

– with Ball Valve

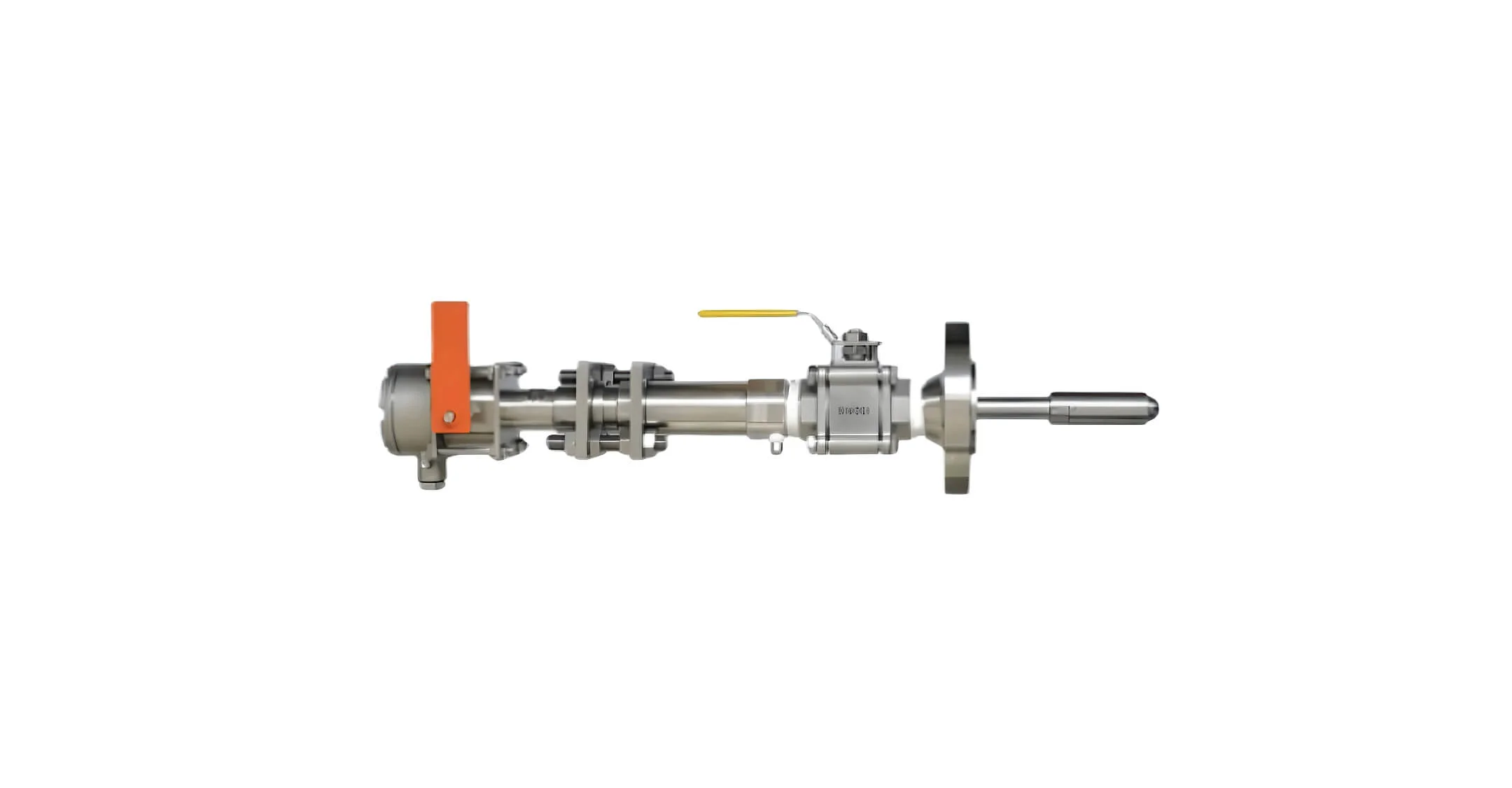

– with DBB Valve

Removable Pig Detector

Non-intrusive Pig Detector

Basic Features and Parameters:

- Type: Intrusive/Non-intrusive

- Connection type: Welded connection/ Flange connection

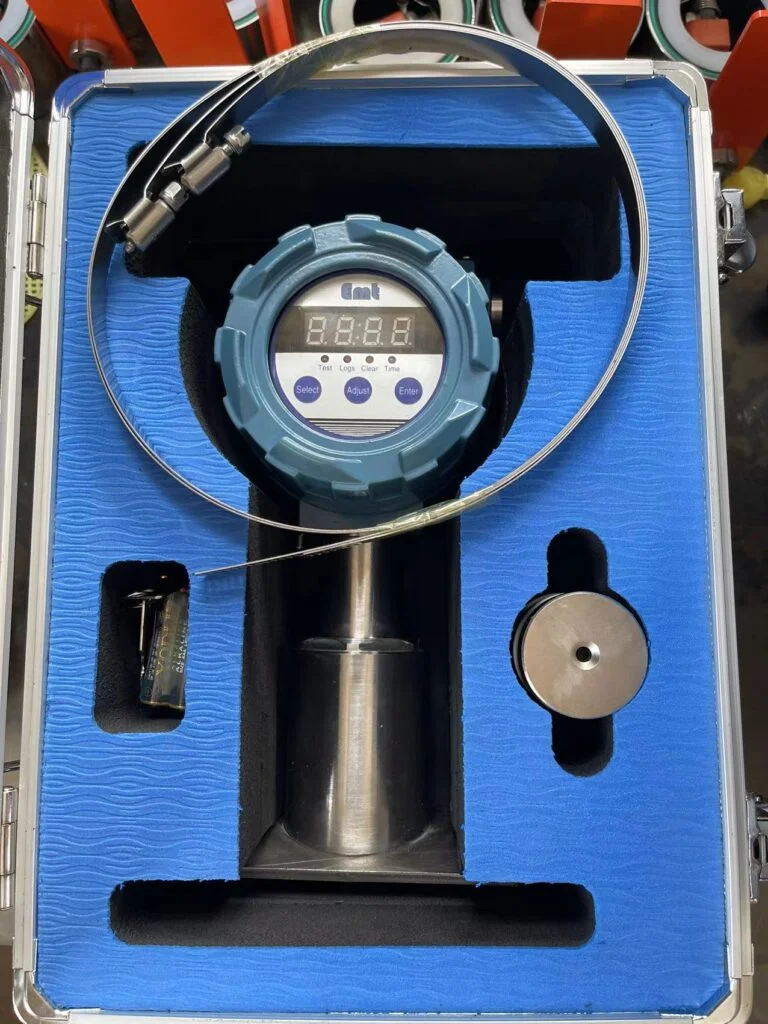

- Indicator feature: Manual reset flag(Manual reset flag combined with electrical signals and Date and time display combined with electrical signals can also be made)

- Installing type: 2”Welded base, NPT connection/ Flange connection

- Trigger type: Uni-directional/ Bi-directional

- Insert depth(In pipe): 13mm

- Plug body length: Settled

- Insert depth adjustment: 20mm

- Operating temperature: -20~120℃/Meet customer requirements

- NACE MR 0175: Yes

- Ingress protection: IP66

- Explosion-proof class: Exd II BT4

- Include isolation valve: No

- Remove under pressure: Yes

- Retriever: Special retriever

- Internal part material: 316SS is the standard configuration (DSS and INCONEL can meet customer needs)

- Nipple/Body material: A105 is standard configuration (304SS/316SS/DSS/INCONEL can meet customer needs)

III. Applications of Pig Detectors

Pipeline Cleaning

Pigging is commonly used for cleaning pipelines. Cleaning pigs are devices that scour the inner walls of the pipeline to remove accumulated debris or deposits, such as rust, scale, or sludge. Pig detectors play a crucial role in these operations by tracking the pig’s progress through the pipeline, ensuring that it completes its journey and does not get stuck.

Pipeline Inspection

Inspection pigs, also known as “smart pigs,” are used to inspect pipelines for potential damage or integrity issues, such as corrosion, cracking, or irregularities in the pipe wall thickness. Pig detectors are crucial in these operations, providing real-time data on the pig’s location and speed, and alerting operators if the pig stalls or deviates from its expected course.

Batching

In multi-product pipelines, pigs are used to separate different substances to prevent cross-contamination. Pig detectors are critical in these operations as they signal when the pig has passed a certain point, indicating that the product changeover is complete.

IV. Advantages of Using Pig Detectors

Pipeline cleaning and maintenance are critical aspects of the oil, gas, and other industries. Pigs are tools used for cleaning and maintaining pipelines, and pig detectors help track the location and speed of these pigs. The use of pig detectors significantly boosts the efficiency and safety of pipeline operations, with benefits manifesting in several ways:

Enhanced Efficiency

- Real-Time Monitoring: The product is for real-time tracking of a pig’s position and speed, which is crucial for pipeline cleaning and maintenance tasks. This real-time tracking ensures that the pig is operating correctly within the pipeline, eliminating the need for repeated cleaning due to pig failure or misplacement.

- Prevention of Blockages: The product can promptly identify anomalies, such as a pig getting stuck or blocked in the pipeline, enabling timely intervention. This preventive measure ensures the continued smooth operation of the pipeline.

Increased Safety

- Reduced Manual Intervention: The use of pig detectors minimizes the need for direct human intervention in the pipelines, thereby reducing the risk of safety incidents caused by human error.

- Prevention of Equipment Damage: Pig detectors allow real-time monitoring of the pig’s operational status. If any anomaly is detected, operations can be halted immediately, preventing further damage and preserving the integrity of both the pipeline and the pig.

In the realm of pipeline maintenance, the adoption of these specialized devices contributes significantly to creating safer and more efficient work environments. By limiting the necessity for hands-on involvement, they considerably decrease the hazards associated with manual handling, thus boosting overall safety measures.

Moreover, these devices play a pivotal role in safeguarding the operational infrastructure. They provide real-time monitoring capabilities, allowing for immediate response to any operational anomalies. This immediate response system ensures that activities can be promptly halted in the event of any irregularities, thereby averting potential damage. In doing so, these tools not only conserve the structural integrity of the pipeline but also extend the lifespan of the cleaning or inspection apparatus by preventing undue wear and tear.

These aspects underscore the importance of such detection devices in today’s pipeline operations, proving them to be indispensable tools in maintaining the smooth functioning and longevity of pipeline systems.

V. The Crucial Role of Pig Detectors in Pipeline Maintenance

Building on their fundamental role in enhancing safety and operational efficiency, pig detectors are pivotal in pipeline maintenance. They ensure that pigging operations, which are integral to pipeline maintenance procedures, are conducted efficiently and effectively. By tracking the pig’s progress through the pipeline and providing real-time information on its location and status, pig detectors prove invaluable in preventing potential pipeline damage or blockage, should the pig get stuck or lost.

In addition, pig detectors can signal the completion of a pigging operation. This is crucial to prevent unnecessary delays and ensure the timely execution of subsequent tasks. For pipelines transporting different types of products, pig detectors facilitate product changeovers by signaling when a pig, used to separate different substances, has passed a certain point.

With the capacity for real-time monitoring and control of pigging operations, pig detectors significantly enhance overall pipeline integrity and operational efficiency. Their role in pipeline maintenance is therefore indispensable, underlining the interconnected nature of their fundamental functions and their broader contributions to pipeline maintenance.

VI. Conclusion

In conclusion, pig detectors play an invaluable role in the pipeline industry by ensuring the smooth, efficient, and safe execution of pipeline cleaning and maintenance tasks. Their capability to provide real-time monitoring of a pig’s location and speed within the pipeline contributes significantly to operational efficiency and enhances safety. By assisting in preventing blockages and equipment damage, reducing the need for manual intervention, and providing essential data for planning maintenance activities, pig detectors prove to be indispensable tools. They serve as a testament to the crucial intersection of technology and operational excellence in the oil, gas, and other industries that rely heavily on pipeline systems. As we continue to strive for safety and efficiency in these industries, the importance of tools like pig detectors cannot be overstated.

Reviews

There are no reviews yet.