Description

Introduction of Bandlock

EMT Bandlock Closures provide for quick access to any pressure vessel, whether horizontal or vertical. Unlike other quick-opening closures, they can be opened and closed safely and quickly—any size unit can be opened or closed in less than a minute, with no special tools required.

EMT is a world leader in the manufacture of quick-opening closures. With over 20,000 units in use globally, our EMT Bandlock sets the standard in high-pressure application closures.

Bandlock’s design was considerably aided by computer-aided technologies. The main pressure-loaded parts were designed to be lightweight by applying finite element analytical techniques and strain gauge proof testing, all while following primary pressure vessel code criteria.

Bandlock Advantages

INTEGRATED SAFETY FEATURES

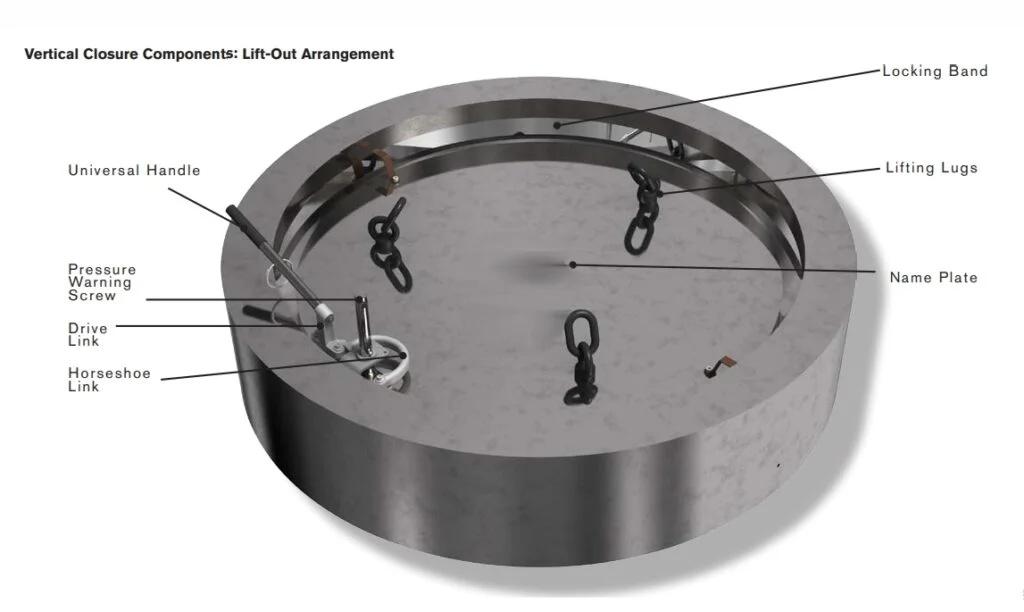

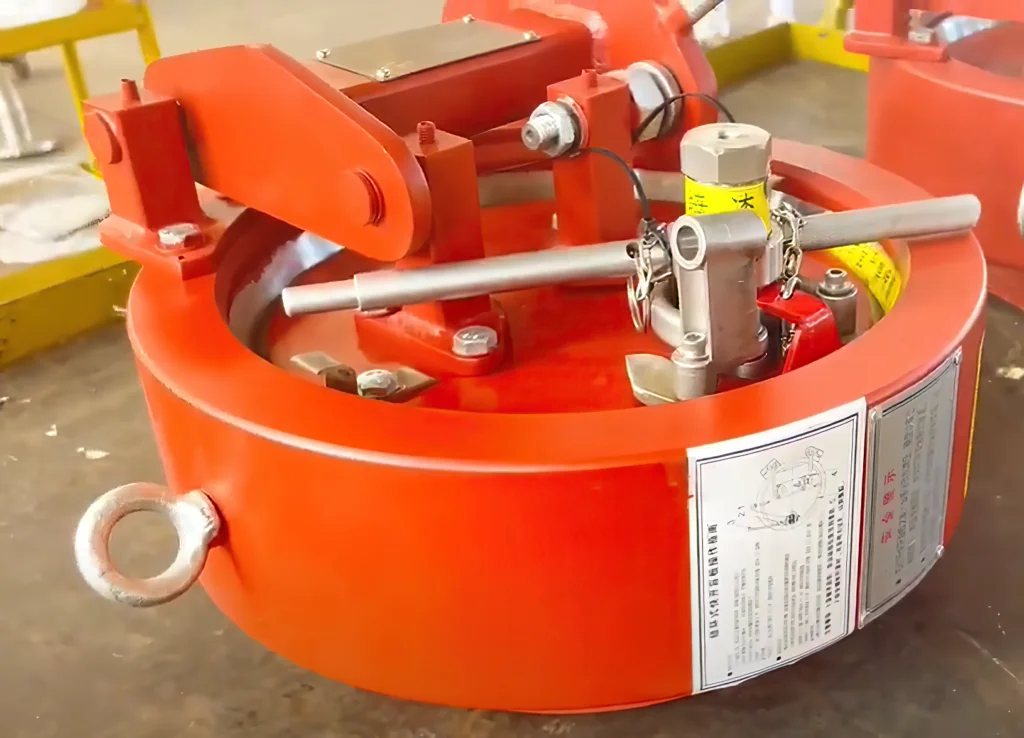

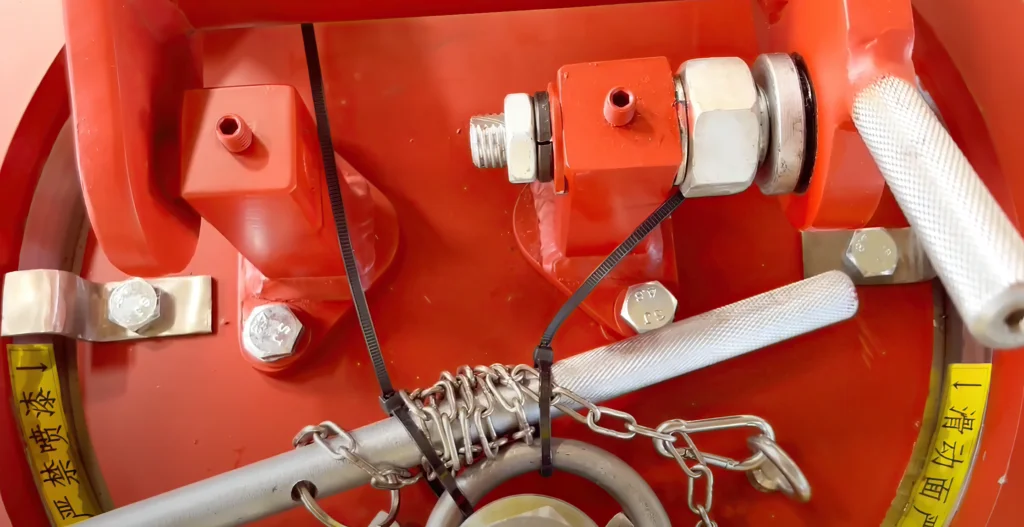

The EMT Bandlock is distinguished by its safety features, which were incorporated throughout the design and manufacturing processes. Within the mechanism, there is a manually operated pressure warning screw that ensures the door cannot be unlocked until the pressure inside the vessel is certified to have been released. Additional safety features, such as mechanical key interlocks, can be incorporated and linked to regulate valve operations. The locking band is constantly visible for ultimate safety assurance, meeting design code demands and allowing the operator to visually verify that the door is securely shut and closed.

DOOR

For horizontal use, the door is designed to pivot twice on hinges with self-lubricating bearings. The fastened positioning enables for wear adjustment and can be set up for right or left swing. A davit is incorporated for vertical installation, allowing the EMT Bandlock door to be lifted and relocated away from the hub. When the diameter of the door exceeds 30″, lifting eyebolts are commonly used in place of the davit, allowing the door to be raised apart.

COMPOSITION OF A SEAL

The standard seal is made of Nitrile material with an 80° shore hardness. Alternatives include Viton, HNBR, and materials resistant to explosive decompression. Depending on the elastomer, temperature compatibility ranges from -45°C to +210°C.

EXAMINATION HYDROSTATIC

While an individual closure hydrostatic test is normally performed as part of the final vessel inspection, it is optional.

UNIQUE SEAL WITH INTEGRATED ANTI-EXTRUSION SPRING

The carefully engineered servo-acting lip seal, which activates at zero pressure, generates a totally airtight seal. For safety and endurance, the seal is located in the door, away from the operational area, in both horizontal and vertical installations, and can be readily fitted without tools. The one-piece mold is available in a variety of elastomers and comes with a stainless steel spring to prevent extrusion and provide complete vacuum capability.

BUILDING MATERIALS

Forged steel hubs with forged or plate steel doors can be supplied to suit all global material criteria. Other materials can be made according to customer needs.

Bandlock’s Essential Characteristics

Rapid Access: Bandlock enables quick access to pressure vessels, boosting maintenance efficiency and saving downtime.

Horizontal or Vertical Operation: Horizontal or vertical operation: It is adaptable and may be used horizontally or vertically, making it suited for a wide range of applications.

Scalability: The Bandlock design by GD Engineering can be upscaled to meet very large diameter closures for various industrial needs.

Enhanced Safety: Quick-opening closures, such as Bandlock, are developed with safety in mind, ensuring secure and regulated access to pressure vessels.

Bandlock Applications

Quick-opening blind plates are widely used in equipment such as filters, tanks, filter separators, metering skids, cyclone separators, heat exchangers, and more in diverse areas such as natural gas, chemical, and metallurgy. These are horizontal and vertical pressure vessel devices that operate at high pressure, have a big volume, and must be opened and closed on a regular basis. Oil, gas, water, and non-corrosive chemical raw materials are all appropriate mediums (highly corrosive mediums should be processed with other materials such as stainless steel). The temperature range is -40°C to 100°C.

Technical Specifications

| Design Pressure | 1.6MPa-30MPa |

| Corrosion Allowance | 2mm |

| Work Medium | Oil, Natural gas, Water and ore pulp, etc. |

| Seismic Fortification Intensity | 7 Degrees |

| Opening Time | Within 60s less than 200N |

| Size Range | 6″ to 100″ Nominal diameter |

| Class Ratings | ASME 150# through to 2500# |

| For Pressures in excess of 2500# please contact EMT | |

| Closure Orientation | Horizontal or Vertical |

| Termination Design Specifications | ASME B31.3, B31.4, B31.8 |

| Other International standards are available on request | |

| Types of Connection | Butt Welded, Butt Welded with miter for inclined/declined vessels, reduced access or flanged to clients’ requirements |

| Elastomeric Sealing | Nitrile, Viton, and Rapid Gas Decompression Resistant. Other material options available on request |

| Standard Closure Finish | Removable rust preventative for the client to finish paint after welding to the vessel |

Frequently Asked Questions

- What maintenance is required for the Bandlock system?

Bandlock is designed for low maintenance, but it’s recommended to periodically check the seals and mechanical parts for wear and tear. Regular cleaning and lubrication will also prolong its operational life. - Is training required to operate the Bandlock system?

While Bandlock is designed for ease of use, it’s beneficial for operators to undergo training to understand its operation, safety features, and maintenance requirements. - How does the Bandlock system ensure a secure seal?

Bandlock uses a robust clamping mechanism and high-quality seals to ensure a leak-proof closure. The pressure warning screw prevents accidental opening under pressure, ensuring a secure seal. - Are spare parts readily available for the Bandlock system?

Yes, spare parts including seals, locking bands, and pressure warning screws are readily available from the manufacturer. - Is the Bandlock system compatible with other quick open-closure systems?

While Bandlock has its unique design and operation, it can be integrated into systems that previously used other types of quick open closures. Technical consultation is advised for such adaptations. - Can the Bandlock system withstand corrosive environments?

Yes, the Bandlock system is built using materials that resist corrosion. For specific corrosive conditions, it’s recommended to discuss these with the manufacturer for the best material selection. - What is the lifespan of the Bandlock system?

The lifespan of a Bandlock system depends on several factors including operational conditions, maintenance, and frequency of use. With proper care, it can provide reliable service for many years. - What should be done if a Bandlock system doesn’t seal properly?

If the closure doesn’t seal properly, it’s advised to check the condition of the seals and ensure the locking band is properly engaged. If problems persist, contact the manufacturer or a service professional. - What happens if the Bandlock closure is accidentally opened under pressure?

Bandlock features a pressure warning device that prevents the closure from being opened if the vessel is under pressure, adding an extra layer of safety to its operation.

Summary

With over 20,000 units in service worldwide, EMT’s Bandlock is a widely renowned quick-opening closure system utilized in high-pressure applications. Its unusual design enables quick, horizontal, or vertical access to any pressure vessel, and it can operate at high speeds securely. A manually actuated pressure warning screw and a visible locking band are included in the Bandlock system. The door pivots on self-lubricating bearings and is wear and swing direction adjustable. The usual seal is constructed of Nitrile with an 80° shore hardness, however, other materials are available. Bandlock is used in a variety of applications, including pipeline pig traps, filters, coalescers, strainers, separators, meter skid systems, and hydrocyclones. The system features a design pressure range of 1.6MPa-30MPa, a corrosion allowance of 2mm, and an opening time of less than 60 seconds for units less than 200N. It has a nominal diameter range of 6″ to 100″ and is available in both horizontal and vertical orientations.

Reviews

There are no reviews yet.