Description

Introduction

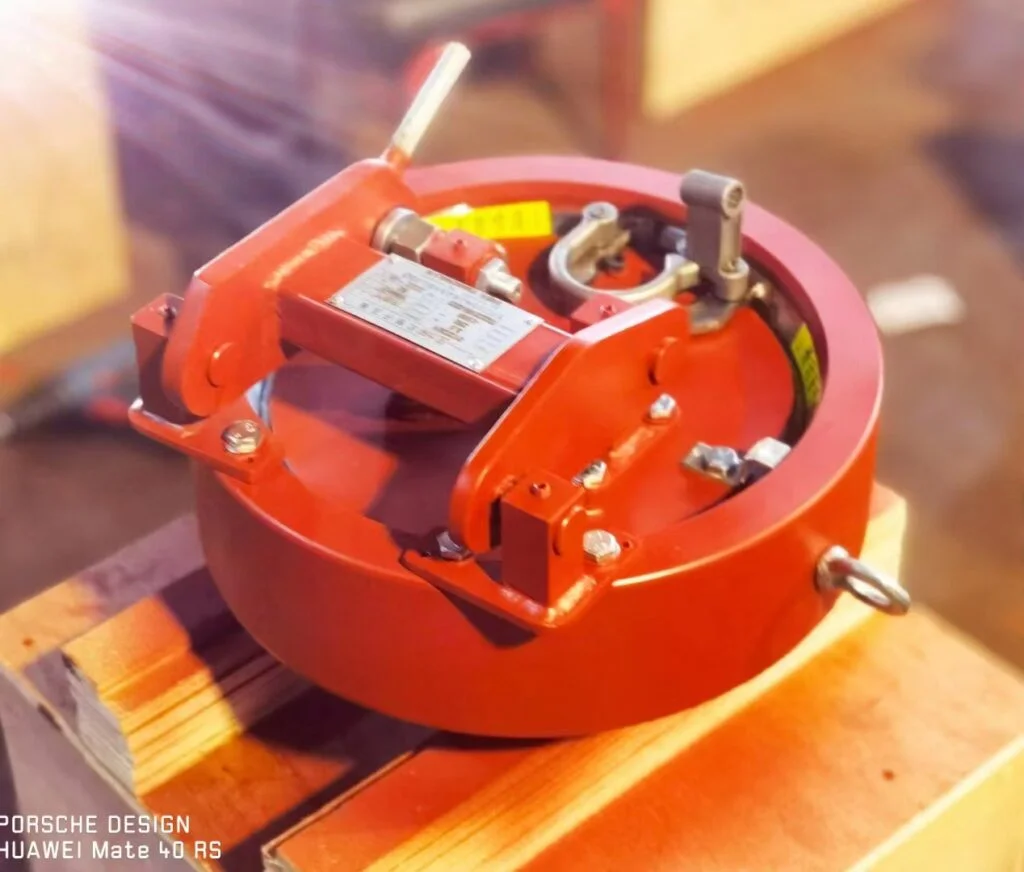

High Pressure Quick Open Closures are pressure-containing components that facilitate rapid and easy access to the interior of a pipe system. These devices play a crucial role in many industrial pipelines and pressure vessels by enabling quicker opening and closing operations, thereby enhancing operational productivity.

Designed for safety and convenience, these closures can be opened and closed within seconds without any special tools, marking a significant improvement over traditional bolted flange connections. They are particularly beneficial in systems requiring frequent interior access, such as pig launchers and receivers, due to their quick actuation.

Common applications of QOCs include pig launchers and receivers, pressure vessels like filter units, and vertical vent stack blowdowns. They are incorporated into specific pipeline design codes, such as ASME B31.4 for liquid pipelines and ASME B31.8 for gas pipelines. When installed on pressure vessels, they are usually designed in accordance with ASME Section VIII, Division 1.

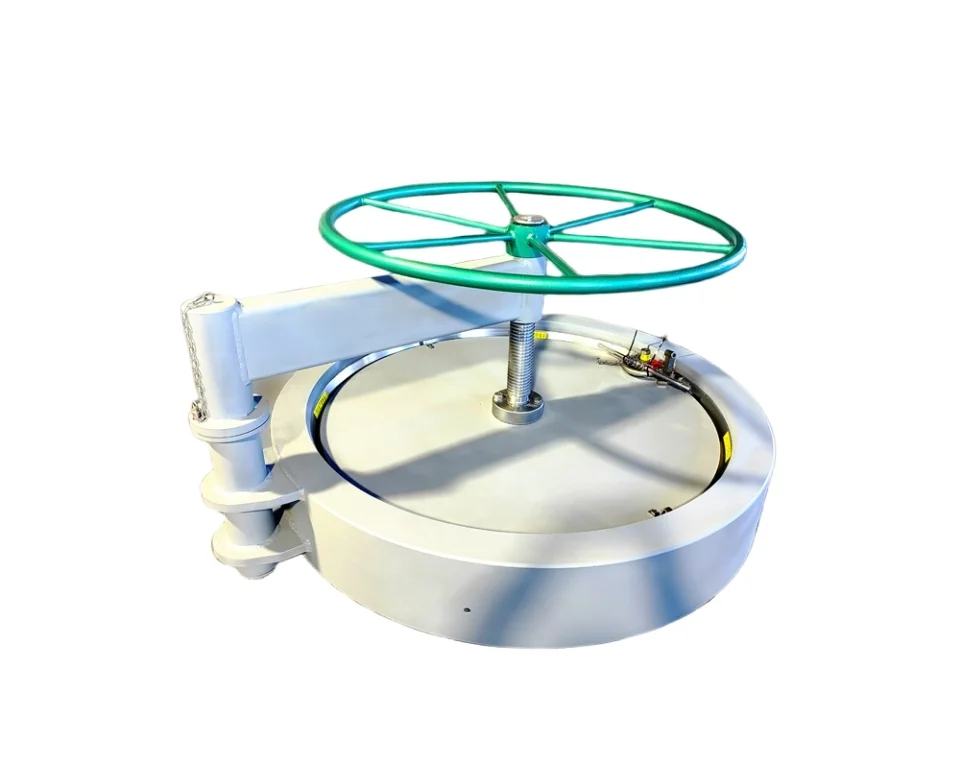

The design and structure of QOCs vary based on their application and the nominal diameter of the pipeline. For instance, pipelines with a diameter ranging from DN100 to DN350 typically employ the bayonet type, while those with a diameter between DN400 and DN1200 often use the lock-ring type.

Instructions for Using a High Pressure Quick Open Closure

- Get Ready

Before proceeding, ensure that the pressure inside the vessel has been completely relieved. This is a crucial safety precaution.

Equip yourself with the necessary safety gear, such as gloves and safety glasses.

Clear the area of any unnecessary personnel or equipment.

- Unlocking the Closure

Locate the locking mechanism or the release lever, typically found on the closure lid as a handle or a wheel.

Disengage the locking mechanism. This is usually done by turning the handle or wheel counter-clock, but the direction can vary based on the design.

Once the locking mechanism is disengaged, slowly open the closure lid. Some designs feature hinges and swing open, while others need to be lifted off.

- Gaining Access to the Vessel

With the closure cover open, you now have access to the vessel for inspection, maintenance, or cleaning.

- Completing the Task

When you’ve finished with the vessel, replace the closure lid. Ensure it aligns properly with the vessel opening.

Engage the locking mechanism by turning the lever or wheel. This is typically done clockwise, but it can vary based on the design.

Ensure the closure lid is securely attached and that the seal is tight.

Product Parameters

- Design Pressure: 1.6MPa-30MPa

- Corrosion Allowance: 2mm

- Seismic Fortification Intensity: 7 Degrees

- Work Medium: Oil, Natural gas, Water and ore pulp etc.

- Opening Time: Within 60 less than 200N

- Opening Type: Vertical or Horizontal

- Nominal Diameter Dn: ≤1600mm

- Design Pressure: ≤40 MPa

- Working Medium: oil, gas, water

- Design Temperature: -50℃~300℃

- Material: carbon steel

- Pipe Thickness: 6mm~100mm

The above is an example of product indicators, other Quick Open Closures specifications are implemented according to industry standards

Safety Considerations for High Pressure Quick Open Closure

Inspect the closure for any signs of leakage, particularly near the seal.

Conduct any necessary pressure tests following your company’s guidelines or the manufacturer’s recommendations.

Safety is paramount in the use of Quick Open Closures (QOCs), as with any operational equipment. These devices come with various safety features and should be operated in accordance with specified precautions and industry regulations.

Safety Features

QOCs often incorporate safety features. A common one is the pressure warning device, which alerts operators to any residual pressure inside the vessel, preventing unintentional opening of the closure before complete depressurization and averting potential accidents.

Mechanical locking is another crucial safety feature present in many QOCs. This mechanism secures the closure in place during operation, preventing inadvertent opening under pressure.

Precautions When Using QOCs

Operators should always ensure all pressure has been completely relieved before attempting to open a closure. Although the pressure warning device is helpful in this regard, operators should also be trained to confirm pressure relief through other means.

Proper maintenance of the closure is also essential. Regular maintenance and timely replacement of worn or damaged parts can prevent closure failure during operation.

Additionally, personnel should be thoroughly trained in the correct procedures for opening and closing the device. This includes knowing how to use any necessary tools and ensuring that the closure is correctly sealed after closing.

Compliance with Industry Standards and Regulations

QOCs should meet the requirements of relevant industry design codes, such as ASME VIII Div. 1, ASME VIII Div. 2, and PD5500. Compliance with these standards ensures that the closure is designed and constructed to withstand the stresses it will encounter during operation.

Many QOCs also bear the ASME U stamp. This mark indicates that the closure has undergone a rigorous in-shop inspection by an ASME-authorized inspector, further certifying its safety.

Conclusion

High Pressure Quick Open Closure serves as an indispensable component in multiple industrial pipelines and pressure vessels. Their new design makes operations more productive by making it easy and quick to get to the inside of pipe systems. This is a huge improvement over traditional bolted flange connections. Their utility is especially pronounced in systems that need frequent interior access, such as pig launchers and receivers.

Their usage spans an array of applications, including pressure vessels like filter units and vertical vent stack blowdowns. Industry-specific pipeline design codes, like ASME B31.4, ASME B31.8, and ASME Section VIII, Division 1, govern how QOCs are built. This makes sure that they are safe to use and have a solid structure.

In addition to their design versatility, and accommodating various pipeline diameters, QOCs are also equipped with crucial safety features like pressure warning devices and mechanical locks. These features are designed to prevent unintentional opening and the potential accidents it could cause. However, the safe operation of these devices also hinges on correct usage procedures, regular maintenance, and comprehensive training of operational personnel.

Lastly, QOCs are expected to comply with the stipulations of key industry design codes. Many also carry the ASME U stamp, symbolizing that they have passed rigorous inspections and meet high safety standards. This reinforces their credibility and assures users of their reliability and safety.

As we move forward, the role of QOCs in industrial settings is set to grow, given their significant contributions to operational efficiency and safety. Their continued development, coupled with strict adherence to safety practices and standards, will ensure that they remain a mainstay in the industry.

Reviews

There are no reviews yet.