Description

I. Introduction

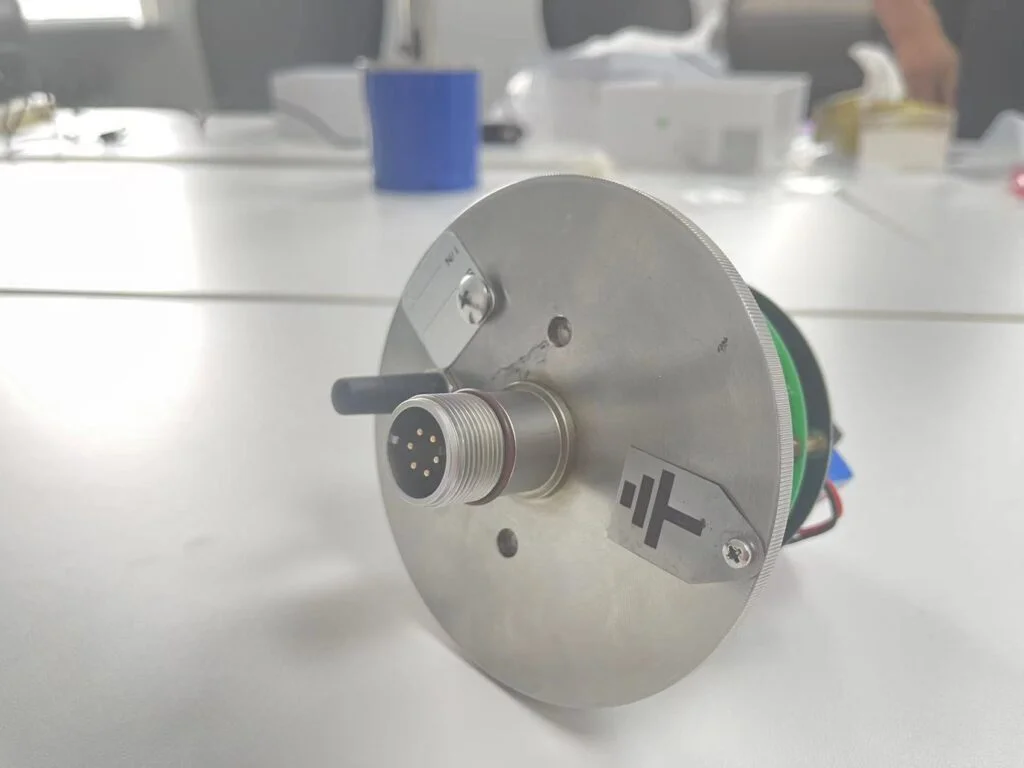

EMT ER Corrosion Probe is a retrievable, fixed-length, electrical resistance corrosion probe, designed for use in high-pressure access systems. The probe, with its fully welded structure and high-temperature glass sintering sealed interface, is well-suited to withstand harsh environments. The probe assembly comprises an extension rod with a sensing element and a threaded connecting seat. Each part of the probe assembly is welded and sealed, and the interface end is sealed by high-temperature glass sintering. The probe sensor can be equipped with a protective cap. After the probe is installed to the hollow plug by using the probe nut and sealing ring, the probe-plug assembly can be installed or retrieved in the process, using a retrieval tool and service valve, without process shutdown.

II. Understanding the ER Corrosion Probe

Specifications

Probe Body: 316SS/ 316LSS/ DSS/ INCONEL is available

Temperature Rating: -200℃~260℃/260℃~450℃optional

Pressure Rating: Less than 45MPa

Mounting: Access System with Hollow Plug

It should be noted that a probe adapter is essential for connecting the collector and it needs to be ordered separately.

To prevent media leakage, several measures have been implemented in the probe design. The measuring element and the probe body are integrally welded, ensuring a secure connection. Furthermore, the probe rod is filled with a filler material that demonstrates high resistance to both heat and pressure. Lastly, the interface is effectively sealed using glass, further enhancing the probe’s leak-proof capabilities.

III. Working Principle of the ER Corrosion Probe

The Electrical Resistance (ER) Corrosion Probe operates based on the principle of electrical resistance. It is a widely used method for measuring corrosion, particularly in environments involving high-pressure systems.

Electrical Resistance Technique

In the electrical resistance technique, the corrosion rate is determined by measuring the increase in the electrical resistance of a metal probe as it undergoes corrosion. As the metal corrodes, it becomes thinner, which in turn increases its electrical resistance. This change in resistance can be measured and used to calculate the rate of corrosion.

The principle behind this is Ohm’s law, which states that the resistance (R) of a conductor is directly proportional to its length (L) and inversely proportional to its cross-sectional area (A). Hence, as the metal corrodes and its effective cross-sectional area decreases, its resistance increases.

Operation of the ER Corrosion Probe in a High-Pressure System

The ER Corrosion Probe, such as Model EMT-EP100, is designed to function effectively in high-pressure systems. The probe assembly comprises an extension rod with a sensing element and a threaded connecting seat, all of which are welded and sealed together to withstand high pressures.

The probe is installed into the high-pressure system via a hollow plug. The plug is secured using a probe nut and sealing ring, preventing any leakage under high pressure. The probe can be installed or retrieved during the process using a retrieval tool and service valve, without requiring a process shutdown.

The probe’s sensing element, which is in contact with the medium in the pressure system, undergoes corrosion over time. This corrosion leads to a change in the element’s electrical resistance, which can be measured and used to calculate the corrosion rate. The data collected by the probe can then be transmitted to a collector via a probe adapter.

IV. Benefits of Using the ER Corrosion Probe

Preventing Unnecessary Shutdowns

One of the key advantages of ER Corrosion Probes is their ability to prevent unnecessary shutdowns. Traditional corrosion monitoring methods often require system shutdown for inspection and maintenance, which can be costly and time-consuming. However, with ER Corrosion Probes, corrosion monitoring can be performed while the system is still operational. The data collected by these probes can inform decisions about when maintenance is truly necessary, thereby avoiding unnecessary shutdowns and optimizing system uptime.

Durability in Harsh Environments

Lastly, ER Corrosion Probes are known for their exceptional durability in harsh environments. The fully welded structure, the use of high-resistance filler in the probe rod, and the glass-sealed interface contribute to the probe’s ability to withstand high pressures and temperatures. This robust construction ensures that the probes can reliably function even in extreme conditions, providing consistently accurate corrosion data over their operational lifespan. This durability reduces the need for frequent replacements, contributing to cost savings and system longevity.

V. Applications of the ER Corrosion Probe

Various Industries

In the oil and gas industry, these probes are used extensively in pipelines, refineries, and offshore platforms. They help monitor the corrosion rates of equipment exposed to corrosive substances, preventing unexpected failures and ensuring the integrity of the infrastructure.

In the chemical industry, ER Corrosion Probes are used in reactors, storage tanks, and pipelines to monitor the effects of various chemical reactions on the equipment. This helps in maintaining the operational safety and efficiency of the chemical processes.

In the power generation sector, especially in nuclear and thermal power plants, these probes are critical for monitoring the corrosion rates in boilers, heat exchangers, and cooling systems. This helps in maintaining the efficiency of power generation and extending the equipment’s lifespan.

In the water treatment industry, these probes are used to monitor corrosion in systems exposed to various water qualities, helping to maintain the integrity of the treatment systems.

Specific Scenarios

A specific example of the ER Corrosion Probe’s beneficial application can be seen in offshore oil platforms. These platforms are exposed to harsh environmental conditions and corrosive seawater. Using ER Corrosion Probes, the corrosion rates of the structural components can be continuously monitored, enabling timely maintenance and preventing catastrophic failures.

In another instance, in a chemical plant dealing with highly corrosive substances, the ER Corrosion Probe helped identify an increased rate of corrosion in a reactor. This early detection allowed for immediate preventive actions, averting potential equipment failure and production loss.

VI. Conclusion

In summary, EMT ER Corrosion Probes, such as Model EMT-EP100, play an integral role in numerous industries by providing real-time, accurate corrosion monitoring. This proactive approach to corrosion management significantly improves system efficiency, prevents unnecessary shutdowns, and extends the lifespan of equipment. The robust design of these probes ensures their durability even in harsh environments, further enhancing their value.

The importance of ER Corrosion Probes extends beyond just their immediate benefits. The ability to monitor and manage corrosion effectively is crucial in maintaining the safety and reliability of various systems, particularly in industries such as oil and gas, chemical, power generation, and water treatment. These probes not only help in reducing maintenance costs but also contribute significantly to preventing unexpected failures that could have severe environmental and economic impacts.

As we look to the future, the role of ER Corrosion Probes in corrosion monitoring is expected to expand even further. Developments in sensor technology and data analytics may lead to even more accurate and timely corrosion data, enabling even better decision-making and preventive maintenance. Furthermore, the integration of these probes with digital technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), could open up new possibilities for predictive maintenance and system optimization.

Reviews

There are no reviews yet.