Description

Introduction

Resistance probes, also known as corrosion probes, are essential tools for monitoring and measuring corrosion rates in a variety of industries in different environments. These devices work by detecting changes in resistance caused by the loss of probe material due to corrosion. So that people can understand the corrosion of the pipeline.

Resistance probes are commonly used in industries such as oil and gas, chemical processing, and food and beverage. They play a key role in pipeline maintenance, helping to detect corrosion early and prevent potential failures.

For example, in the oil and gas industry, resistance probes can be used to monitor corrosion in pipelines, storage tanks and ships. In the food and beverage industry, they help ensure the cleanliness and safety of processing equipment by detecting any corrosion that could contaminate the product.

Despite their many advantages, resistance probes also have some limitations. The effectiveness of these tools can be affected by factors such as the characteristics of the pipe, the type of debris, and the material of the probe itself. However, with the right use and maintenance, resistance probes can be a tool for maintaining the integrity and safety of industrial equipment.

Understanding Resistance Probes

What is a Resistance Probe?

The resistance probe is a special instrument used to measure and monitor corrosion rates in a variety of environments. It works by detecting changes in its own resistance caused by material loss due to corrosion. This helps identify the presence and extent of corrosion in structures such as pipes, storage tanks, and ships, making it an important tool for industries such as oil and gas, chemicals, and food and beverage.

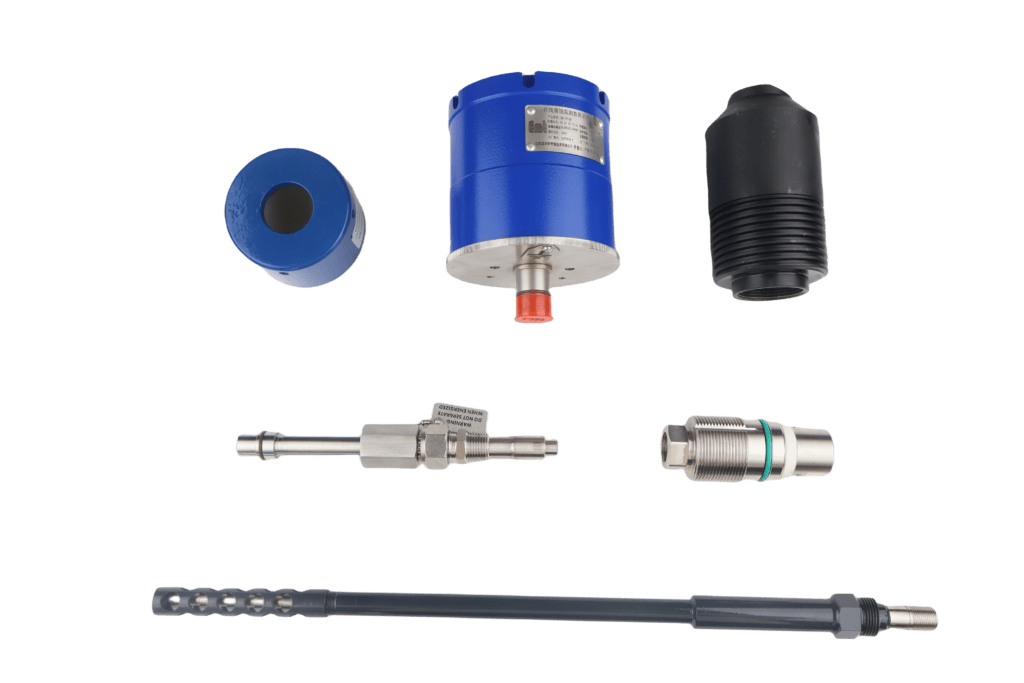

Assembly of Corrosion Probe

First, connect the plug assembly to the probe. The seal is represented by the white part of the bridge plug. This seal is counter-threaded, so it must be screwed on in the opposite direction and then secured with a wrench. Next, the assembled plug is inserted into the base, usually welded to the pipe, and tightened. Now, put the shield on the base.

Second, note that the probe adapter has a notch and the probe itself has a keyway. Align these pieces, tighten the threads, and tighten the top nut. The nut is important because it prevents the adapter from rotating during operation.

Third, install a wireless transmitter and power it on, making sure you are not in the blast zone during this process. Connect the two white sockets together. After a few seconds, the green light will flash and then automatically turn off. Once powered on, the protective cover is placed on the wireless transmitter and transported to the site.

Upon arrival at the scene, remove the red protective cap from the wireless transmitter plug. Align the key position on the wireless transmitter with the key position on the adapter. Install the connection nut and tighten with a wrench. Finally, lock everything with screws. With these steps, the installation of the entire equipment is complete.

Usage of Portable Data Logger

First, turn on the power of the tablet and launch the Bluetooth window software. You will notice that the driver software starts and establishes a connection with the device. Now minimize these settings.

Next, open the EMT software and adjust the window Settings to establish a connection to the device. Click “Device Scan”. Once the device is successfully connected, stop the scanning process and continue downloading the data.

You now have access to data from different time periods, which will be automatically converted into data curves. You can click on the data curve to look at it more closely.

Also, you can choose to calculate the corrosion rate. Select a point on the curve as the starting point for data collection, and then select another point as the end point for data collection. Click “Corrosion Rate Calculation”. A value will then appear that will form the basis for the next step in the process.

Applications of Resistance Probes

Use in the Oil and Gas Industry

In the oil and gas industry, resistance probes play a vital role in maintaining pipeline integrity. They monitor corrosion rates in pipes, tanks and other containers, enabling early detection and prevention of potential failures. These probes help ensure the safety, efficiency and service life of the industry’s critical infrastructure.

Role in the Chemical Processing Industry

Resistance probes are also important in the chemical processing industry. They provide real-time data on corrosion rates of chemical storage tanks and processing equipment. This information helps maintain the integrity of the system, prevent leaks that can lead to hazardous chemicals, and optimize the service life of the equipment.

Implementation in the Food and Beverage Industry

In addition to these industries, resistance probes can be used in a variety of industries, including water treatment, power generation and Marine. In water treatment facilities, they help control corrosion of tanks and pipes, thereby ensuring water quality. At power plants, they monitor corrosion in boilers and cooling systems to prevent breakdowns. In the shipping industry, they are used to monitor corrosion of hulls and offshore structures, helping to improve safety and durability.

Other Industries Benefiting from Resistance Probes

In addition to these industries, resistance probes can be used in a variety of industries, including water treatment, power generation and Marine. In water treatment facilities, they help control corrosion of tanks and pipes, thereby ensuring water quality. At power plants, they monitor corrosion in boilers and cooling systems to prevent breakdowns. In the shipping industry, they are used to monitor corrosion of hulls and offshore structures, helping to improve safety and durability.

Conclusion

Resistance probes play a vital role in monitoring and managing corrosion rates and are an indispensable tool for industries as diverse as oil and gas, chemical processing, and food and beverage. Despite their challenges, they dramatically improve the safety, efficiency and longevity of operations by providing early corrosion detection and timely intervention. Their importance extends to preventing potential disasters, protecting the environment and promoting public health. With the right use and maintenance, resistance probes can provide valuable real-time data to inform critical decisions, underscoring their important role in industrial safety and efficiency. As the industry continues to evolve, so does the importance of these tools, underscoring their important contribution to maintaining the integrity of industrial equipment and infrastructure.

Reviews

There are no reviews yet.