Description

Pig Signaler

An Adjustable Pig Signaler is a kind of equipment used in the oil and gas industry. Its purpose is to detect the movement of cleaning pigs. When cleaning pigs pass through the location, the Pig Signaler will respond to show the passage of cleaning pigs. Different pig signalers use different techniques to indicate the passage of cleaning pigs. Pig Signaler with flags, for example, show the passage through the direction of the flag. They illustrate the passage of the signal when paired with electrical signals. Display of the date and time The passage is displayed on the screen using Pig Signaler.

Introduction

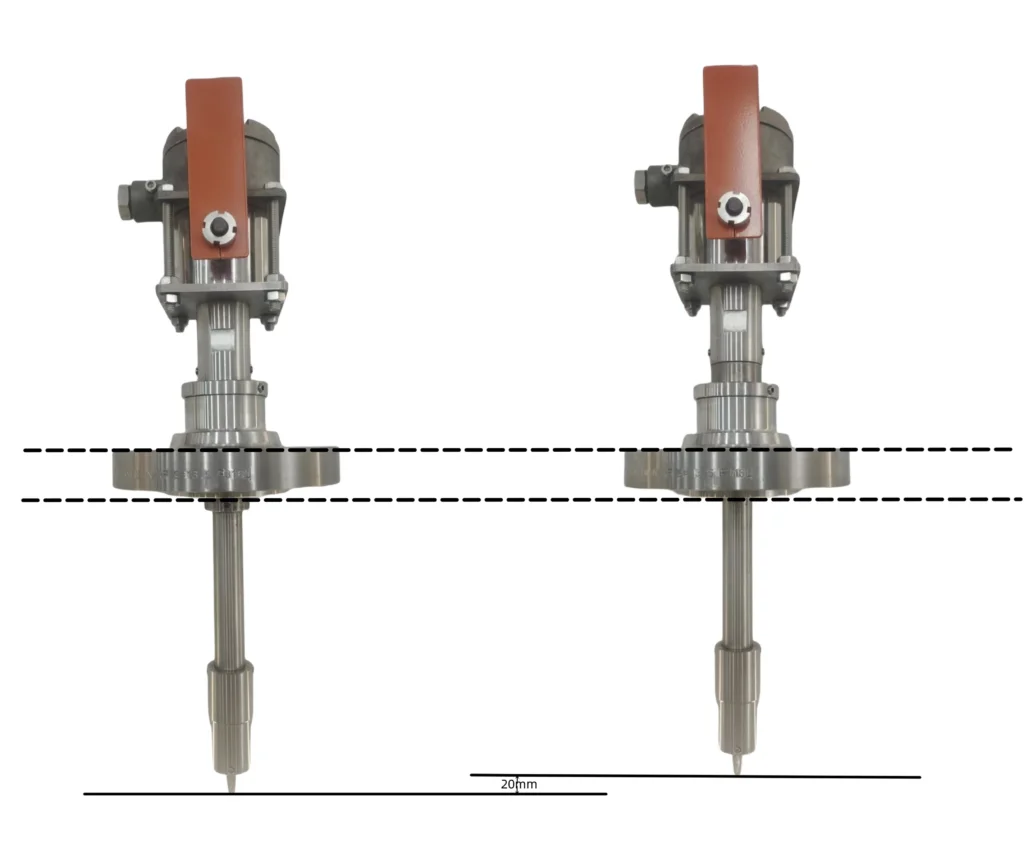

The Adjustable Pig Signaler in this image is an intrusive type. A flange connects it to the pipe. Its insertion depth into the pipe can be changed by 20mm. The Pig Signaler in this image is a manual reset flag with electrical signals. This one has a bi-directional trigger. A unidirectional trigger is also available. This can be tailored to the needs of the customer.

Inside the pipe, an invasive Pig Signaler is mounted to physically interact with the pig as it travels through. When the Pig Signaler comes into contact with the pig, mechanical switches, magnets, or signals send the signal. Intrusive Pig Signalers may necessitate the installation of a special fitting in the pipeline to allow for their insertion and removal.

Advantages of Adjustable Pig Signaler

- Firstly, this Pig Signaler is integrated with an electrical signaling system. This feature eliminates the need for close inspection to confirm the passage of the Pig. The signal can be received remotely, providing a convenient way to gather information about the progress of cleaning pigs without needing to be near the Pig Signaler.

- Secondly, the insertion depth of the Pig Signaler is adjustable by 20mm. This adjustable range allows for more precise insertion into the pipe, catering to various pipeline configurations and ensuring effective operation.

- Thirdly, the Pig Signaler utilizes a flange connection as opposed to a welded connection. Unlike welded Pig Signalers, where the base material must match the pipe material, the flange connection does not require material congruity. The only necessity is size compatibility, making it easier to attach to the pipe and broadening its applicability.

- Lastly, this Pig Signaler is bi-directional. This means it can effectively transmit the passage of the pig regardless of whether the pig is moving in the launch direction or the reverse direction. This feature ensures consistent and reliable signaling, enhancing the efficiency and reliability of pipeline-pigging operations.

Basic Features and Parameters

- Type: Intrusive

- Connection type: Flange connection

- Indicator feature: Manual reset flag combined with electrical signals (Manual reset flag and Date and time display combined with electrical signals can also be made)

- Installing type: 2” Flange. As per ASME B16.5 (Class 150–2500),

- Plug body length: 200mm/Meet the actual needs

- Insert depth adjustment: 20mm

- Operating temperature: -20~120℃/Meet customer requirements

- NACE MR 0175: Yes

- Ingress protection: IP66

- Explosion-proof class: Exd II BT4

- Remove under pressure: No

- Trigger type: Bi-directional (Uni-directional trigger can also be made)

- Internal part material: PTFE-coated A105N is standard configuration (304SS/316LSS/DSS/INCONEL/As per MR can meet customer needs)

- Junction box material: aluminum alloy/316SS

- Switch type: DPDT/2*SPDT

- Switch rating: DC24V 3A/DC24V 5A

Functions

They are typically mounted on the pipe to determine whether or not the pig passes. It is often put at the start or end of the pipe. When a pig passes, the signaler transmits a signal to the control room indicating that the pig has passed. At the same time, it offers information about the cleaning pig’s whereabouts. Its information is critical for pipeline operators to monitor the pipeline’s condition. Operators can notice problems such as corrosion, cracking, or other damage in the cleaning pig’s passage situation, which may require maintenance or repair. Pipeline inspection and maintenance utilizing pigs and these products is required on a regular basis. Because it can contribute to the safe and efficient transfer of oil and gas.

Working Principles of Adjustable Pig Signaler

The Pig Signaler is equipped with a bi-directional trigger located at its base, designed to be inserted near the pipe wall. As the cleaning pig traverses the pipeline, it interacts with this trigger, causing the firing pin to activate and subsequently pulling the connecting rod housed within the sealing bushing. As a result of this action, the flag shaft, under the influence of the torsion spring, undergoes a 90-degree rotation. This movement transitions the flag from a horizontal orientation to a vertical position. The flag’s location then serves as a visible indicator, enabling personnel to accurately determine the pig’s position within the pipeline. To reset the flag after the pig has passed, it simply needs to be rotated counterclockwise. This design allows for continuous and seamless operation of the Pig Signaler, facilitating efficient pipeline pigging processes.

Operation Cautions

The passing of a cleaning pig via the horizontal or vertical direction of the flag is determined by operators. What must be remembered is that the flag must be manually reset to the non-trigger condition before use. The flag should be pressed down by the operator until it is horizontal. When the pig pulls the trigger, the flag swings more than 45 degrees. The flag then shifts from a horizontal to a vertical orientation. This shows that a pig has traveled through this section of the pipe.

Intrusive or Non-intrusive Pig Signaler?

The selection of either of the two pig signals is influenced by a number of parameters, including the type of pig utilized, the size and material of the pipe, and the operating conditions. Non-invasive pig types are less difficult to install and maintain, but they may not be as accurate or dependable as invasive pig types. Intrusive pigs, on the other hand, can enable more precise and consistent detection. However, they necessitate more complicated installation processes.

A device placed in a pipe is an intrusive one. A non-intrusive pig signaler is a device that is utilized outside of the pipe. The majority of the time, intrusive pigs are mechanically linked to the pipes. This, however, necessitates a flange connection or a pipe hole. When flange connection criteria are not met or the aperture is inaccessible, a non-intrusive pig signaler is employed. One that is not invasive can be placed anywhere in the pipes. Installation is less difficult than with invasive pig signalers.

Conclusion

In conclusion, the Adjustable Pig Signaler serves as an essential piece of equipment in ensuring the efficiency, safety, and longevity of pipeline operations, particularly within the oil and gas industry. Its ability to provide real-time, accurate information about the passage of cleaning pigs offers a significant advantage in maintaining the health of these vital infrastructures.

The various innovative features of the Pig Signaler, including its adjustable insertion depth, bi-directional trigger, and flange connection, enhance its versatility and effectiveness in a range of pipeline configurations. The integration of an electrical signaling system also ensures remote monitoring, thereby reducing the need for close inspection and elevating operational convenience.

Whether you opt for an intrusive or non-intrusive Pig Signaler will depend on your specific needs and circumstances, including pipeline size, material, and operating conditions. Regardless of your choice, regular inspection and maintenance of the pipelines using pigs and Pig Signalers are crucial to ensuring the safe and efficient transfer of oil and gas.

For more information about the Adjustable Pig Signaler or any other inquiries, please do not hesitate to contact us. Our experienced team is always on hand to provide professional advice and assistance tailored to your specific needs. Your pipeline’s health and efficiency are our top priorities.

Reviews

There are no reviews yet.