Description

I. Introduction

Types:

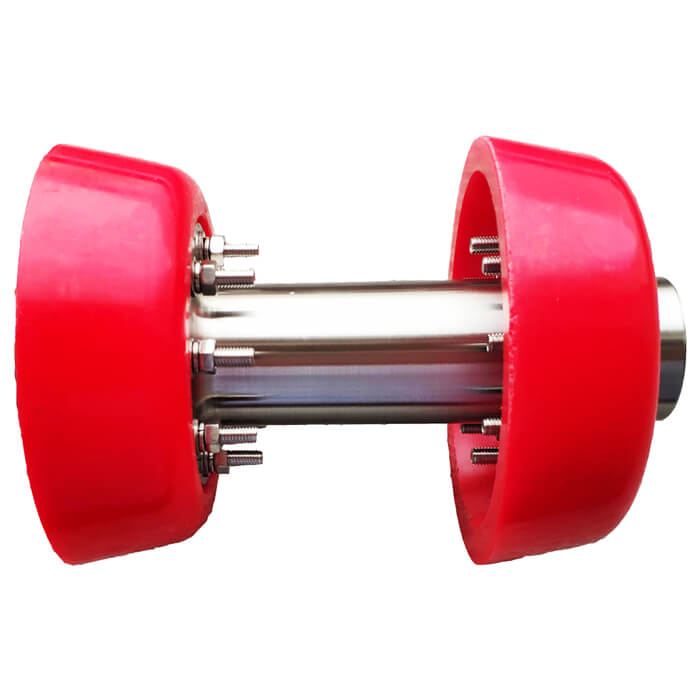

Cleaning pigs come in two primary forms: those equipped with discs and those fitted with cups. There are typically 2-cup, 3-cup, and 4-cup versions available. If additional reinforcement is required, cleaning pigs with cups can be supplemented with discs for easier pipeline entry as well as increased guidance and support. Pigs with discs often feature guiding plates, such as a 4-disc pig with two guide plates or a 6-disc pig with two front guide plates. This arrangement enables bidirectional pipeline navigation. Conversely, pigs equipped with cups are designed for unidirectional movement.

Skeleton Material Options:

Stainless Steel:

We offer three primary skeleton materials, the first of which is stainless steel, including variations such as 316ss, 316lss, and 304ss. Stainless steel’s robustness and hardness are largely due to the presence of chromium and nickel. The chromium forms a protective oxide layer on the surface, safeguarding the metal from corrosion and wear. Nickel enhances the metal’s strength and pliability, increasing its overall hardness. Importantly, stainless steel possesses excellent acid resistance. Pigs with stainless steel skeletons can be supplemented with transmitters, making them an excellent choice if transmitter integration is a requirement.

Carbon Steel:

As an alternative to stainless steel, carbon steel is a more cost-effective material. However, it is not compatible with transmitters due to magnetic field interference, unless the diameter is greater than or equal to 300, in which case the separation allows for non-interfering functionality.

ABS:

For pigs of size less than or equal to DN200, ABS is a viable option. Although it is pricier than the other two materials, its capacity to prevent sparks-induced explosions makes it a safe choice. ABS is also lighter and exhibits strong acid resistance.

Please contact us for any specific material requirements.

Key Features:

High flexibility.

More-resistant.

Run longer in the pipelines.

Good sealing property.

Can operate bi-directionally.

II. Background of Pipeline Pigging

A. Importance of Pipeline Maintenance in the Oil and Gas Industry

The importance of pipeline maintenance in the oil and gas industry cannot be overstated. Pipelines form the critical foundation of the energy transportation infrastructure, ensuring the efficient and safe delivery of oil and gas from extraction sites to processing facilities, storage tanks, and ultimately to consumers. Unmaintained or poorly maintained pipelines can present significant operational challenges, including reduced flow efficiency, increased energy consumption, and potential environmental hazards due to leaks or spills. Furthermore, corrosive materials and residues can accumulate over time, causing further damage to the infrastructure and potentially leading to costly system failures. Thus, regular pipeline maintenance, which includes the use of tools like cleaning pigs, is essential to the safe, efficient, and sustainable operation of oil and gas pipelines, protecting both the economic interests of the industry and the environmental health of our planet.

B. Introduction to Pipeline Pigging

Pipeline pigging is a crucial process in the oil and gas industry, used for the cleaning, inspection, and maintenance of pipelines. The term “pigging” comes from the squealing noise that early devices made while traversing the pipeline, reminiscent of a pig’s squeal. The “pigs” utilized in this process are specialized devices that are inserted into and travel through the pipeline for various operations. They can perform a multitude of functions, from cleaning and removing deposits or build-up inside the pipeline to inspecting the integrity of the pipeline for any signs of damage or corrosion. This process not only helps optimize the flow efficiency and capacity of the pipelines but also plays a vital role in preventing potential environmental hazards and ensuring the safe and efficient operation of the pipeline system.

III. Detailed Look at Cleaning Pigs

A. Definition and Use of Cleaning Pigs

A cleaning pig, often just referred to as a ‘pig,’ is a device used in pipeline maintenance to clean and inspect the insides of pipelines. These pigs are designed to move through the interior of a pipeline, driven by the flow of the product being transported, or in some cases, a separate propellant.

The term ‘pig’ was initially an acronym for ‘Pipeline Inspection Gauge,’ but it’s also said that the name was derived from the squealing sound the early models made while moving through the pipeline, which was reminiscent of a pig’s squeal.

Cleaning pigs come in various designs but are typically cylindrical or spherical in shape and are sized to match the internal diameter of the pipeline. These devices are equipped with special scraping or brushing mechanisms that remove deposits or sediments, such as scale, rust, or other debris, that can accumulate over time and affect the pipeline’s efficiency.

Cleaning pigs are not only used in the oil and gas industry but can also be found in other industries where pipelines are used for the transportation of products, including the chemical and food industries. They are an essential tool in maintaining the health and efficiency of a pipeline system, contributing to safer operations, lower operational costs, and improved product quality.

B. How Cleaning Pigs Work in Pipeline Maintenance

Cleaning pigs are specialized tools used in pipeline maintenance that aid in the removal of unwanted debris, sediment, rust, or scale that can accumulate within the pipeline over time. The mechanism of their operation is relatively straightforward.

- Insertion: The cleaning pig is inserted into a section of the pipeline known as a ‘pig launcher.’ The pig launcher is essentially a section of the pipe that can be sealed off and has an opening through which the pig is introduced.

- Travel: Once the pig is inserted, the pressure of the fluid (oil, gas, etc.) being transported through the pipeline is used to push the pig along the pipeline. In some cases, a propellant gas can also be used to propel the pig if the pipeline is being inspected during a shutdown or maintenance period.

- Cleaning: As the pig travels through the pipeline, it scrapes off and collects any debris or buildup. Cleaning pigs are designed to fit snugly within the pipeline to ensure that they make contact with the interior surfaces of the pipe, allowing them to remove debris effectively. The type and design of the cleaning pig used depend on the nature of the debris to be removed and the specific characteristics of the pipeline.

- Removal: After traversing the length of the pipeline, the pig reaches a ‘pig receiver’ or ‘pig trap’ at the other end. This is another section of the pipeline that can be closed off and safely opened to remove the pig and the collected debris.

- Inspection: After the pig is removed, it is inspected for signs of wear or damage which could indicate problems within the pipeline. The debris removed by the pig can also be analyzed to provide additional information about the condition of the pipeline.

In this way, cleaning pigs help maintain the efficiency, safety, and longevity of pipelines in various industries, particularly the oil and gas sector.

C. Advantages and Limitations of Cleaning Pigs

Advantages of Pipeline Cleaning Pigs

- Improved Efficiency: By removing debris, rust, scale, or other buildups, cleaning pigs can greatly enhance the flow efficiency of the pipeline, ensuring optimal operation.

- Preventive Maintenance: Regular cleaning can help prevent corrosion and other forms of degradation that can lead to pipeline failures, leaks, or bursts.

- Safety and Environmental Protection: By maintaining the integrity of the pipeline, cleaning pigs helps prevent potentially hazardous leaks of oil or gas that could pose safety risks and environmental contamination.

- Cost Savings: Cleaning pigs can detect issues early before they become more serious (and expensive) problems. Their use can reduce the need for costly repairs or replacements and extend the lifespan of the pipeline.

- Versatility: Cleaning pigs come in a variety of types and sizes, allowing them to be used in different kinds of pipelines with various diameters and for different types of debris.

Limitations of Pipeline Cleaning Pigs

- Pipeline Compatibility: Not all pipelines are suitable for pigging. Some pipelines may be too small, have too many bends, or contain sections of varying diameters that make it difficult for the pig to move through.

- Incomplete Cleaning: Some types of debris or scale may be too hard or firmly attached for the pig to remove, requiring additional cleaning methods.

- Potential Damage: If not used correctly, pigs can potentially cause damage to the interior of the pipeline, particularly if the pipeline is old or already in poor condition.

- Operational Disruptions: The pigging process may require the partial shutdown of the pipeline, which can disrupt operations, especially if the pipeline is part of a continuously operating system.

- Maintenance Requirement: Pigs themselves require regular maintenance and inspection to ensure they are functioning correctly and not causing damage to the pipelines.

VI. Conclusion

Cleaning pigs play an essential role in the maintenance and operation of pipelines across various industries, particularly in oil and gas. They are designed to travel through the pipeline, removing unwanted debris such as sediment, rust, or scale that can accumulate and impair the pipeline’s efficiency. This process not only enhances the flow efficiency and capacity of the pipelines but also contributes to their longevity by preventing corrosion and other forms of degradation.

Moreover, cleaning pigs can help detect issues early before they evolve into more serious and costly problems, thereby reducing the need for extensive repairs or replacements. They play a key role in preventive maintenance, reducing operational costs, and extending the lifespan of the pipeline infrastructure.

Furthermore, by maintaining the integrity of the pipelines, cleaning pigs contributes to safety and environmental protection. They help prevent potentially hazardous leaks of oil or gas that could pose both safety risks and environmental damage. However, their application is limited by certain factors such as pipeline design and size, type of debris, and operational disruptions.

Overall, the importance of cleaning pigs in pipeline maintenance is multifaceted, encompassing operational efficiency, safety, cost-effectiveness, and environmental responsibility.

Reviews

There are no reviews yet.