Katrangan

Gambaran Umum Weld Babi

Sinyaller Babi Weld digunakake kanggo pigging minyak, gas, banyu, lan pipa transmisi liyane, lan tandha-tandha babi weld minangka alat ngadili lemah, utawa ora. Sampeyan ora mung gampang diinstal nanging uga bisa nyukupi syarat-syarat macem-macem pipeline kanggo indikasi. Sistem operasi Inggris, interaksi komputer-trep lan intuisi. Nalika nyoba, mung kudu ngembelake indikator menyang pipa supaya bisa ditindakake.

Sinyaller Weld Babi minangka peralatan sing dibutuhake kanggo operasi reresik ing pipa. Nduwe akeh kaluwihan: pisanan, struktur kasebut gampang. Kapindho, pandhuan intuisi. Kaping telu, linuwih, regane murah, lan sapiturute, kontak listrik uga bisa ditambahake, lan sinyal bisa ditularake bisa ditularake kanthi jarak adoh, entheng, lan listrik.

Dasar weld nalika welded ing pipa, lan striker kasebut dilebokake ing pipa. Nalika babi pipa ngliwati, striker dicenthang, lan batang puteran lan indikator plate ing pipa dibuwang, lan banjur kanthi visual ngreset papan indikator lan pengungkit pendulum kanthi manual. Kanggo ngindhari salah, biasane ora dirancang kanthi otomatis ngreset. Saliyane entuk kekuatan kompresif, indikasi utamane kanggo nyukupi syarat nyegah karat, njamin panyeget, lan nyegah bocor.

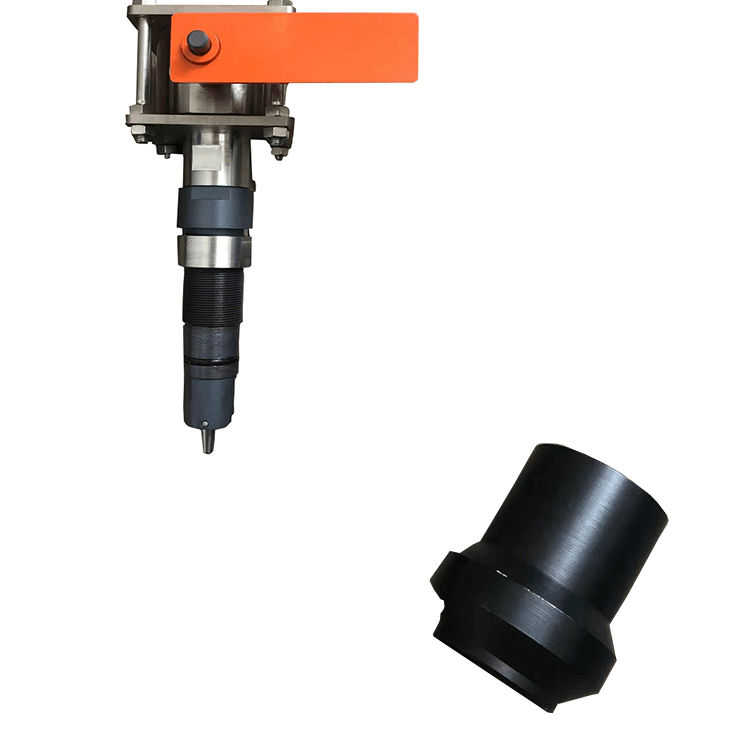

Kanggo alasan iki, kabeh bagean puteran ing sesambungan karo cairan digawe saka baja tahan karat lan bahan tahan karat. Awak utama lan batang puteran disegel karo rong cincin karet, plug skru paling ndhuwur disegel karo cincin karet, lan dhasar utama disegel karo cincin karet. Cincin sealing kudu dilindhungi, amarga iki mung kanggo njamin nglawan bocor. Supaya bisa adaptasi karo macem-macem pipa diameter lan diameter bal, permukaan busi instalasi saka basa indikator lan dawa rod ayunan kudu diatur miturut.

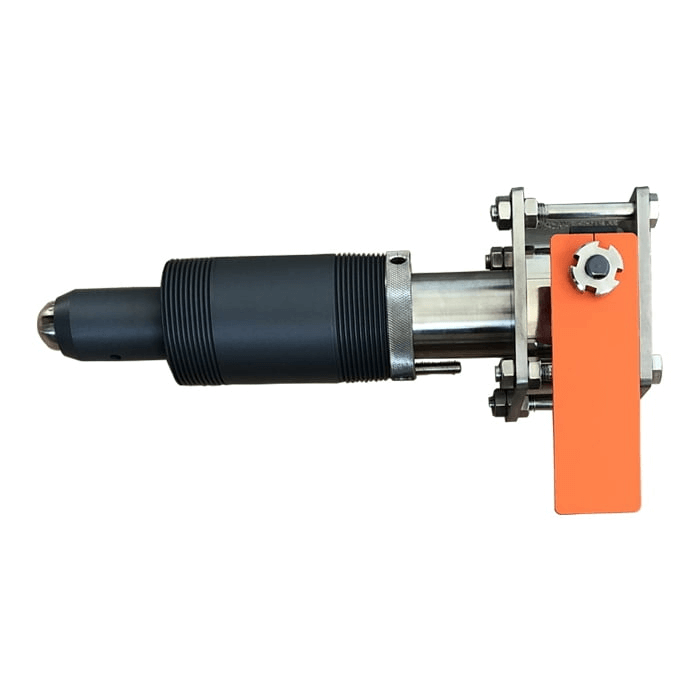

Struktur dhasar signaller babi weld (ndeleng gambar sing dipasang),

Indikator utamane dumadi saka awak mekanik lan mekanisme tampilan

- Pemicu: bisa diputer ing loro arah.

- Plug Screw: Hubungi plug standar 2 ", sing cocog karo kahanan instalasi kanthi tekanan.

- Dasar: Digawe saka baja karbon, wesi baja, utawa 304 stainless steel kanthi kinerja welding sing apik.

- Cincin sealing.

- Tappet.

- Cincin sealing.

- Spring.

- Mungkasi mesin cuci (mungkasi skrip).

- Nambah tappet kandang jaran.

- Sistem lever.

- Awak ndhuwur.

- Tappet.

- Ngencengi ngawut-awut.

- Rod Tocor Inner: Push kanggo nggawe Jam Kontrol Jam Control Control: Bisa menehi tandha indikator mekanik kanggo ngadeg, tampilan digital wektu, lan transmisi remot.

- Mekanisme tampilan: Miturut kabutuhan pangguna, Jam Kontrol Kepala lan Indikasi Mekanik Bisa diinstal nganggo Digital Digital

Tampilan utawa listrik, cahya, swara, lan sumber sinyal liyane.

Metode instalasi tandha weld babi:

- Sadurunge nginstal, priksa manawa mekanisme mekanik lan tampilan indikasi sing fleksibel lan dipercaya, banjur tindakake struktur lan instruksi instalasi.

Iki tujuane kanggo ngilangi awak utama mesin lan weld ing basa lan pipa kanthi kapisah.

- Base Welding:

- Instalasi tanpa tekanan: ngresiki situs instalasi, mbusak kabeh lampiran, lan mbabarake warna saka logam.

Gelang dhasar (diagram orientasi sing nganggo) supaya arah slotting ing sisih ndhuwur dhasar padip pipa utawa tandha ing sisih ndhuwur pipa (arah sing ana ing sisih ndhuwur. Compress pangkalan kanggo nyegah obah utawa deflection sajrone welding. B. Instalasi ing tekanan: (waca manual instruksi saka mesin pengeboran). CATETAN: Nalika welding basis ing pipa, tekanan P ing pipa kudu diwatesi.

Formulasi Pitungan: 2/ T-C) 0.72kgf / cm2

Δ; Watesan bahan asil.

t: pipeline wall thickness mm

C: jumlah ketebalan tembok tambahan (panyebaran negatif ambegan, sangu korosi, lan sapiturute) umume butuh 1,5-2mm.

D: Pipa njaba Diameter MM.

C: Sawise welding lan instalasi awak utama mesin wis rampung, miturut struktur lan diagram instalasi, ing

Badan utama mekanik diinstal ing urutan, lan mekanisme tampilan disambungake kanthi ngawut-awut kanthi cepet miturut struktur lan diagram, lan arah mekanisme tampilan bisa diatur kanggo gampang.

Napa sampeyan butuh signaller babi weld?

Pipa reresik rutin bisa nambah efisiensi transportasi.

Sinyaller babi bakal mbantu sampeyan konfirmasi manawa babi wis liwati.

Fitur dhasar utawa parameter pipa signaller Weld Babi | ||||

| Pig Detector Pipeline | B | C | D | |

| Jinis | Intrusif | |||

| Indicator feature | Manual reset flag | Manual reset flag combined with electrical signals | Date and time display combined with electrical signals | |

| Installing type | 2″Flange. As per ASME B16.5 (CLASS150~2500) | |||

| Plug body length _Correspond to the total standoff | 200mm/Meet the actual needs | |||

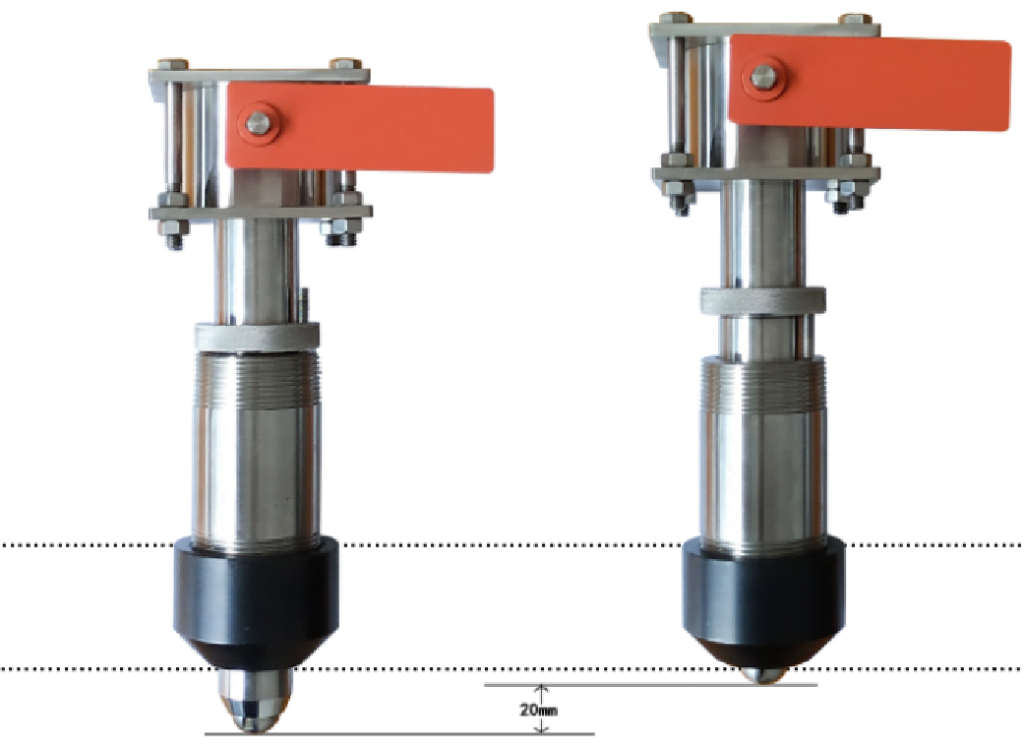

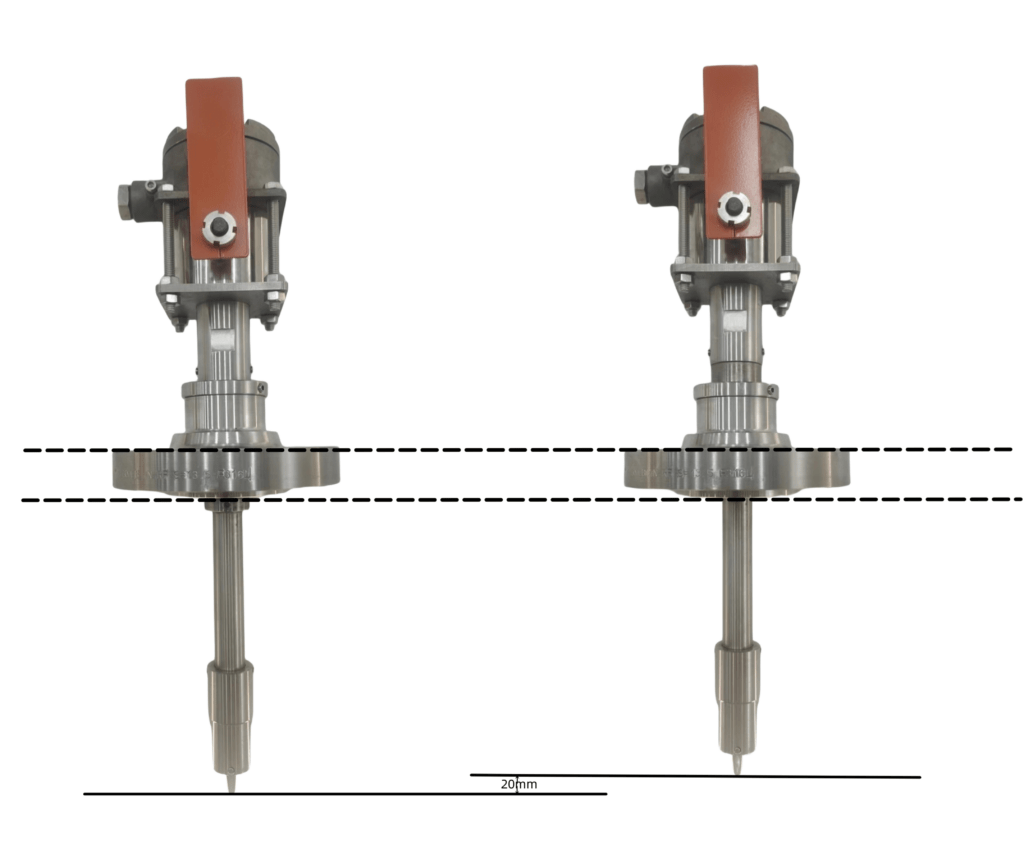

| Insert depth adjustment | 20mm | |||

| Operating temperature | -20~120℃/Meet customer requirements | |||

| NACE MR 0175 | Ya | |||

| Ingress protection | IP66 | |||

| Explosion-proof class | ExdⅡ BT4 | ExdⅡ BT4 | ||

| Remove under pressure | Ora | |||

| Fitur Opsional | ||||

| ● Konfigurasi standar ○ Konfigurasi opsional - ora ana | ||||

| Tipe pemicu (B-bi-arah / u-uni-arah *) | ● / ○ | |||

| Bahan bagean internal (316L SS / DSSS / Inconel) | ● / ○ / ○ | |||

| Flate / Bahan Body (PTFE dilapisi A105N / 304ss / 316lss / DSSS / Inconel / Kaya saben mr) | ● / ○ / ○ / ○ / ○ / ○ | |||

| The position of the Internal liquid surface (High_Need to heating/Low_With no need for heating) [Only uni-directional pig detectors] | ● / ○ | |||

| Bahan kothak Junction (Aluminium Aluminium / 316ss) | - / - | ○ / ● | ● / - | |

| Tipe Ngalih (DPDT / 2 * SPDT) | - / - | ○ / ● | ○ / ● | |

| Ngalih Rating (DC24V 3A / DC24V 5A) | - / - | ● / ○ | ● / - | |

| Ukuran Sambungan Elektronik (M20 × 1,5 (F) / 1/2"NPT (F)) | - / - | ● / ○ | ● / - | |

| * Standard configuration of Uni-directional trigger is ball shape. | ||||

| Corresponding relations between the trigger and Insert depth (In pipe) | ||||

| Tipe pemicu | Bi-Directional | Uni-arah | ||

| Lebokake ambane (ing pipa) | 21mm | 13mm | ||

Pipeline Welding Process

Kualitas yaiku isi proses konstruksi pipa minyak lan gas, saéngga seri kerja ditindakake kanthi kualitas. Ing laku, penekanan diselehake kanggo ngontrol operasi pipo sing welding kualitas. Miwiti proses welding, tindakake proyek sing apik ing proses kontrol sing welding. Nguatake kontrol bahan, personel lan faktor liyane kanggo njamin keamanan lan kualitas pipa panggunaan ing tahapan mengko. 1 Proses Pipa Petrochemical Pipeline

Saiki, proses welding utama saka pipeline Petchemical yaiku 😀 Arc Welding. Ing operasi penipuan pipo, sisih ngisor welding nganggo welding busur, sing bisa njamin efek welding. Miturut elektrods sing beda, welding busur bisa dipérang dadi leleh sing dilelur lan lebur kutub corong polong 2 karbon dioksida welding sing dilindhungi gas. Ing aplikasi praktis, perlu kanggo njlentrehake posisi welding lan syarat teknis. Sadurunge welding, alur kudu di resiki, lan lapisan minyak lan cat ing lumahing loro-lorone kudu di resiki. Kajaba iku, peralatan lan rute udhara kudu dicenthang. Proses welding karbon dioksida Gas sing dilindhungi gas biasane ngetrapake deoxidasi komposit Si lan MN, lan efek welding luwih apik. Pangisi kanggo welding electrode busur.

Generally speaking, in the petrochemical pipeline welding operation, after the bottom welding operation is completed, the slag and other impurities generated by the welding operation should be cleaned up in time. If a hidden problem is found, remove it, weld it, and ground it again. When filling with electrode arc welding, it is necessary to ensure that the position of the bottom weld and the weld is staggered by more than 10mm, and the electrode with a diameter parameter of 3.2mm is used in the middle position. If the pipe wall thickness parameter is 9mm, the welding rod is set at the middle seam of the three-layer weld, and the diameter parameter is 3~5mm.

English

English العربية

العربية Deutsch

Deutsch Bahasa Indonesia

Bahasa Indonesia Português

Português Русский

Русский Español

Español

Ulasan

Durung ana review.