Description

Features of the EMT Retrieval Tool and Servo Valve

The EMT Retrieval Tool and Servo Valve come with a host of features designed to enhance safety and improve operational efficiency.

No Externally Moving Parts: The absence of externally moving parts contributes significantly to safety during field retrievals. This design helps prevent accidents, reducing the risk of injuries to personnel and damage to assets. It also simplifies the design, which can lead to fewer mechanical failures.

Compact Size: The small size of the EMT Retrieval Tool and Servo Valve offers substantial flexibility in choosing optimal monitoring locations within a plant. This compact design requires minimum operational space, making it an ideal choice for facilities where space is at a premium or where the tool needs to be installed in hard-to-reach locations.

Threadless Design: The tool and valve have no threaded sections between the plug and fitting, eliminating the risk of galling and stuck probes. This feature enhances the reliability of the tool and valve, reducing the likelihood of operational issues and the need for maintenance.

Lightweight: The low weight of the EMT Retrieval Tool and Servo Valve contributes to safe and convenient operations. It is easier to handle and maneuver, reducing the physical strain on operators. This feature also makes it simpler to transport the tool and valve between different locations within a plant.

- Design Pressure: 2500 PSI (17.2 MPA), 6000 PSI (41.3 MPA)

- Design Temperature: -4℉ ~ 302℉ (-20℃ ~ 150℃), -15℉ ~ 400℉ (-26℃ ~ 204℃)

- Easy to use and cheap: The EMT Retrieval Tool is simple to use; you can search “EMT Retrieval Tool” on YouTube and see how we replaced the corrosion coupon within 12 minutes.

Letter | Description | Maximum Pipeline Size | ||

12″ | 24″ | 36″ | ||

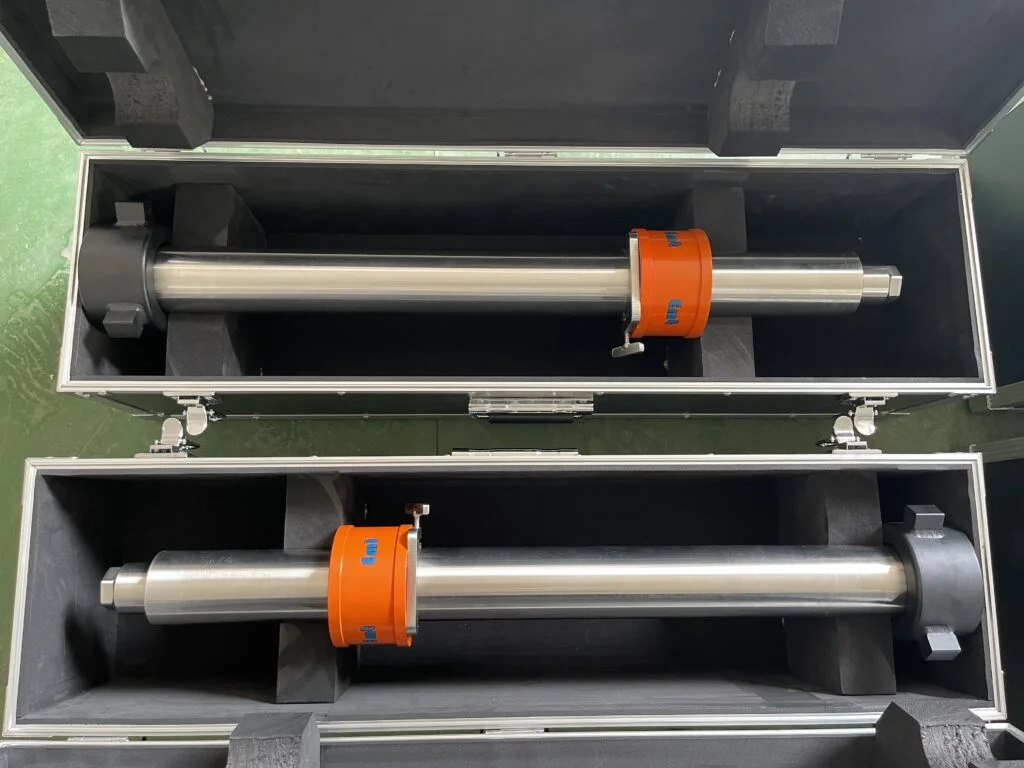

A | Retriever (mm) | 710 | 1000 | 1300 |

B | Retriever and Service Valve (mm) | 985 | 1275 | 1575 |

C | Stroke Available (mm) | 600 | 881 | 1184 |

Weights (kgs) | 25.4 | 27.6 | 30 | |

Introduction

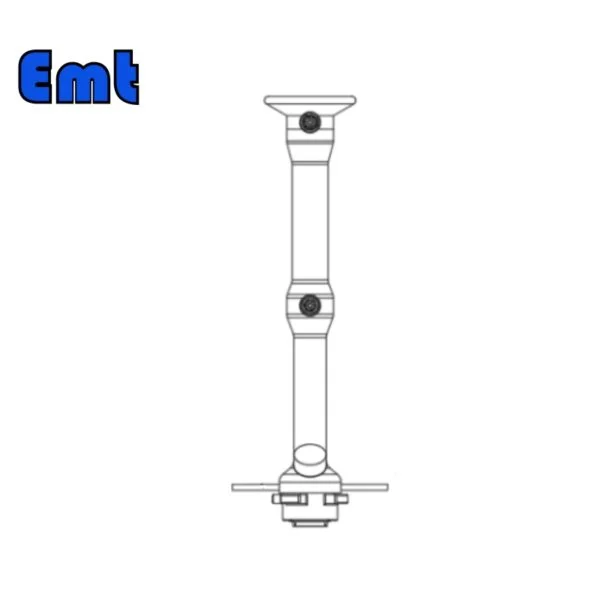

- Retrieval Tool: The Retrieval Tool is a device designed specifically for the safe and efficient retrieval or installation of various equipment, such as chemical injection quills and corrosion coupons. Its design is compact, with no external moving parts and lightweight for easy operation.

- Servo Valve: The Servo Valve is a device that precisely controls fluid flow. The valve is of moderate size, with no threaded interfaces and no external moving parts, all of which contribute to enhanced safety and operability.

- Product Base: This is a component used for installing and securing the Retrieval Tool and Servo Valve. The design of the base allows for easy installation and ensures stability of the equipment during operation.

Pressure Gauge: The Pressure Gauge is a device used for measuring and displaying the internal pressure within the system. This is a crucial component as it allows operators to monitor the working status of the system, thereby enabling the timely identification and resolution of any potential issues.

Technical Specifications

Pressure Compatibility: P≤45Mpa;

Temperature Tolerance: -20~100℃;

Suitable Pipe Diameter: D≥DN100;

Compatible Fluids: Petroleum products, gas, and other non-corrosive fluids.

Under standard usage conditions, the equipment’s installation height depends on the pipe diameter and is generally not exceeding 1.5 meters;

Equipment Configuration

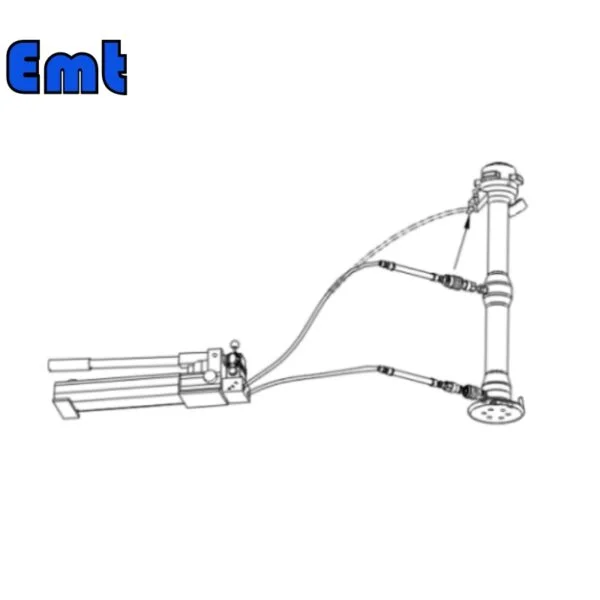

Hammer Nut: It links the base and the Service Valve and comes with a PTFE coating.

Service Valve: A connector for the Retriever, it’s used for adjusting the internal pressure of the pressure removal tools, and it’s also coated with PTFE.

Bleed Valve: Crafted from stainless steel, it’s utilized to discharge the internal pressure within the pressure removal tool.

Bypass Valve: This stainless steel component balances the internal pressure of the pressure removal tool.

Adapter: This stainless steel component is used for connecting the corrosion coupons and the Retriever.

Plug Drive: Made from stainless steel, it is employed for the removal and installation of the drive plug of corrosion coupons.

Plug Lifter: Composed of high-intensity magnetic steel, it’s used for the connection of internal and external magnetic steel plugs.

Stop Block: A stainless steel component for securing the Plug Lifter.

Retriever: A stainless steel component that connects to the gear plate valve, utilized for the elevation and installation of corrosion coupons.

Applications of EMT Retrieval Tool and Servo Valve

- Oil and Gas Industry: The EMT Retrieval Tool and Servo Valve find extensive applications in the oil and gas industry. They are routinely used in operations such as retrieving and installing chemical injection quills and corrosion coupons. Chemical injection quills are used to deliver chemicals directly into the center of a pipeline, which is crucial for preventing issues such as corrosion and bacterial growth. Corrosion coupons, on the other hand, allow for monitoring of the corrosion rates in pipelines, helping to predict and prevent catastrophic failures.

- Chemical Industry: In the chemical industry, these tools are used to control the flow of various chemicals throughout the processing stages. The Servo Valve’s precise control of fluid flow is essential in processes that require exact measurements and flow rates.

- Water Treatment Plants: EMT Retrieval Tools and Servo Valves are also used in water treatment facilities. They assist in the maintenance and control of various equipment and processes, including chemical dosing systems and filtration units.

Real-World Examples

Let’s look at a couple of real-world scenarios where these tools are employed:

- Pipeline Maintenance: In an oil pipeline system, the EMT Retrieval Tool can safely remove a corrosion coupon from the pipeline. This coupon, which has been exposed to the same conditions as the pipeline, can then be analyzed to gauge the rate of corrosion in the pipeline, enabling preventative measures to be taken if necessary.

- Chemical Processing: In a chemical plant, a Servo Valve might be used to accurately control the flow rate of a chemical in a reaction process. The precision of the Servo Valve ensures the correct amount of the chemical is delivered, aiding in the consistency and quality of the end product.

Conclusion

Their applications span across various industries, including oil and gas, chemicals, and water treatment, making them invaluable to processes requiring the precise control of fluid flow or safe, efficient retrieval of in-line instruments. Their ability to withstand a wide range of pressure and temperature conditions speaks volumes about their versatility.

In a world increasingly focused on safety, efficiency, and precision, the EMT Retrieval Tool and Servo Valve stand out as tools designed for the future. As we move forward, we hope to see further enhancements in their design and functionality, making them even more indispensable in their respective fields.

Reviews

There are no reviews yet.