Вот краткое введение в различные типы трубопроводные свиньи Предоставлено EMT (или обычно встречается в операциях по техническому обслуживанию и очистке трубопровода):

1. Сплошные литые свиньи

- Описание: Сделано из полиуретана или другого прочного материала.

- Использовать: Идеально подходит для уборки, партии и измерения.

- Функции: Никакие движущиеся части, устойчивые к износу и коррозии, не могут обрабатывать умеренный мусор.

2. Абс Свиньи

- Описание: Свиньи с Акрилонитрил бутадиен стирол (АБС) Компоненты, часто используемые в сочетании с другими материалами.

- Использовать: Подходит для общей очистки и подготовки к проверке.

- Функции: Легкий, устойчивый к воздействию и экономически эффективный.

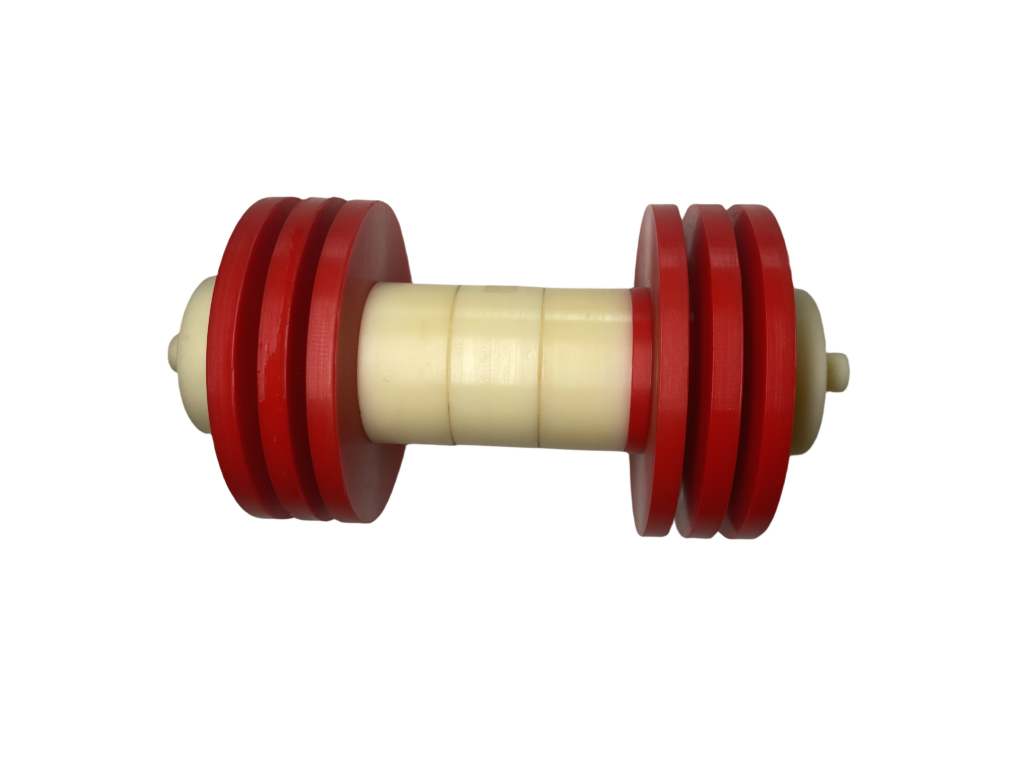

3. чашка свиней

- Описание: Особенности гибкие чашки (обычно полиуретан), которые образуют герметизаторы на стенке трубы.

- Использовать: Используется для очистки, удаления жидкости и разделения.

- Функции: Можно добавить несколько чашек для лучшей способности к уплотнению и соскоб.

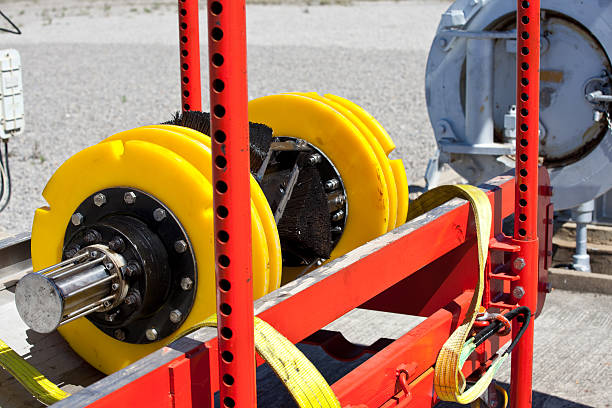

4. Дисковые свиньи

- Описание: Похоже на чашки свиней, но используйте плоские или вогнутые диски вместо чашек.

- Использовать: Отлично подходит для очистки и очистки трубопроводов.

- Функции: Нижнее трение, чем чашки свиней, подходящие для пробежек на дальние расстояния и высокоскоростных потоков.

5. пена свиней

- Описание: Сделано полностью из пены с открытыми или закрытыми клетками, иногда покрытая полиуретаном.

- Использовать: Используется для сушки, очистки и обезвоживания трубопроводов.

- Функции: Легкий, гибкий, может легко ориентироваться в изгибах и изменениях диаметра.

6. Ball Pigs

- Описание: Сферические свиньи, изготовленные из твердых или надувных материалов, таких как резина или пена.

- Использовать: Обычно используется для удаления жидкости или разделения продукта.

- Функции: Простая конструкция может течь с продуктом, часто используемым в газовых трубопроводах.