Descrição

Introdução

Os fechamentos rápidos são peças cruciais que fornecem acesso rápido e seguro a vasos de pressão, tubulações e interiores de sistemas semelhantes no mundo das operações industriais. Esses dispositivos mecânicos podem ser abertos e fechados rapidamente, permitindo inspeção, manutenção e limpeza simples, garantindo ao mesmo tempo uma vedação confiável para segurança.

Eles desempenham um papel importante em diversas indústrias, incluindo os setores petroquímico, farmacêutico e de petróleo e gás. Os fechamentos rápidos simplificam os processos operacionais, reduzem o tempo de inatividade e impõem padrões de segurança rígidos, permitindo acesso rápido para tarefas operacionais, manutenção de rotina e intervenções de emergência.

Compreendendo os fechamentos rápidos

Um fechamento rápido é fundamentalmente um dispositivo mecânico criado para oferecer um fechamento confiável em uma tubulação ou vaso de pressão, ao mesmo tempo que permite acesso rápido e simples quando necessário. Eles geralmente são empregados em ambientes industriais onde o tempo de inatividade deve ser mínimo e onde inspeções, manutenção ou limpeza frequentes são necessárias.

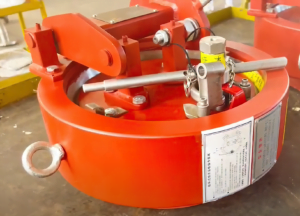

Os fechamentos rápidos funcionam vedando uma tubulação ou vaso sob pressão e a uma temperatura que possa tolerar as condições. As partes fundamentais dos Fechamentos Rápidos são bastante simples, apesar de sua função complexa.

A porta, a vedação e o mecanismo de funcionamento de um fechamento rápido são geralmente suas partes essenciais. A maior parte do vaso ou duto que abre e fecha para permitir o acesso ao interior é a porta. A vedação garante um fechamento hermético que pode resistir às condições internas do sistema e geralmente é construída em um material flexível. A rápida abertura e fechamento da porta é possível graças ao mecanismo de operação, que varia muito entre os vários tipos de fechamentos rápidos.

Quando em uso, a porta do Fechamento Rápido é aberta acionando o mecanismo operacional. Freqüentemente, isso pode ser feito manualmente, sem a necessidade de ferramentas. Quando a tubulação ou vaso é aberto, é possível o acesso ao interior para limpeza, reparo ou inspeção. A porta é então fechada e a vedação é ativada, resultando em um fechamento seguro que pode resistir às circunstâncias de funcionamento do sistema.

Tipos de fechamentos rápidos

Existem muitas variedades diferentes de fechamentos rápidos, cada um com um design e método de trabalho especiais. Os tipos Baioneta, Grampo e Anel de Trava são os três tipos mais populares. Cada tipo tem vantagens distintas e atende a diversas necessidades operacionais e projetos de dutos.

O tipo Clamp possui um mecanismo de fixação articulado que oferece uma vedação confiável e é simples de usar. Por último, mas não menos importante, o tipo de anel de travamento usa um anel de travamento que pode ser liberado rapidamente para abrir a porta enquanto a segura no lugar. A seleção do melhor fechamento rápido para uma determinada aplicação industrial pode ser facilitada se você estiver ciente das diferenças sutis entre os diferentes tipos.

Aplicações de fechamentos rápidos

Os Fechamentos Rápidos são amplamente utilizados em diversos setores, sendo cada uso diferenciado e atendendo às demandas desse negócio.

Os fechamentos rápidos são frequentemente usados em dutos e vasos de pressão na indústria de petróleo e gás para o transporte e armazenamento de produtos petrolíferos. Permitem inspeções e manutenções rotineiras, essenciais neste negócio para estancar vazamentos e garantir o manuseio seguro dessas substâncias perigosas. Por exemplo, um fecho rápido poderia ser instalado na porta de acesso de um tanque de armazenamento de petróleo bruto para facilitar a inspeção e limpeza.

Os Fechamentos Rápidos são amplamente utilizados em aplicações petroquímicas semelhantes às do setor de petróleo e gás. Quando é necessário acesso rápido para limpeza, manutenção ou inspeção, eles são empregados em reatores químicos, separadores e filtros. Um vaso de reator químico, por exemplo, pode ter um fechamento rápido instalado para facilitar a manutenção de rotina e a inspeção das peças internas.

Os Fechamentos Rápidos são empregados no setor farmacêutico em ambientes estéreis onde é necessário um acesso rápido e limpo, como em biorreatores ou fermentadores. Eles garantem que a integridade do sistema seja mantida, ao mesmo tempo que permitem acesso simples quando necessário.

Em unidades filtrantes ou vasos de pressão, o setor de tratamento de água utiliza Fechamentos Rápidos. Eles eliminam a necessidade de tempo de inatividade prolongado, permitindo meios filtrantes rápidos e simples ou substituição de componentes internos.

Estas ilustrações mostram a adaptabilidade e a importância dos Fechamentos Rápidos em vários setores. Eles são uma ferramenta importante em diversas aplicações devido à sua capacidade de oferecer acesso rápido e seguro.

Considerações sobre manutenção e segurança

Para que os Fechamentos Rápidos durem muito tempo e funcionem com segurança, a manutenção adequada é essencial. Verificações regulares ajudam a garantir que o Fechamento Rápido funciona de forma segura e adequada, ao mesmo tempo que evita falhas imprevistas e reparos dispendiosos.

O cuidado regular com os Fechamentos Rápidos normalmente inclui a inspeção e, se necessário, a substituição das vedações, pois uma vedação desgastada ou danificada pode comprometer a integridade da tampa. Para garantir um bom desempenho, o mecanismo de operação deve ser inspecionado frequentemente quanto a desgaste ou danos e lubrificado. É importante procurar ferrugem ou danos na porta e outras peças.

Ao trabalhar com Fechamentos Rápidos, a segurança deve estar sempre em primeiro lugar, principalmente porque são frequentemente empregados em sistemas de alta pressão. Para evitar qualquer liberação inesperada de pressão, é essencial confirmar se o sistema foi completamente despressurizado antes de abrir um Fechamento Rápido. Ao realizar manutenções ou inspeções, devem ser usados equipamentos de proteção adequados, como luvas e óculos de segurança.

Além disso, todos os procedimentos relativos à aplicação, manutenção e segurança dos Fechamentos Rápidos devem ser bem registrados e rigorosamente seguidos. Treinamento regular deve ser fornecido a qualquer pessoa que utilizará ou manterá Fechamentos Rápidos.

Conclusão

Os fechamentos rápidos tornaram-se uma ferramenta vital em vários setores, incluindo os setores petroquímico, de tratamento de água, petróleo e gás e farmacêutico. Sua construção especial permite acesso rápido a vasos de pressão e tubulações, simplificando a inspeção, manutenção e limpeza, preservando a integridade operacional e a segurança.

Eles são inestimáveis em muitas aplicações devido à sua versatilidade e utilidade. A Quick Closures demonstrou repetidamente sua adaptabilidade, desde facilitar a manutenção de rotina na indústria de petróleo e gás até garantir o acesso estéril na indústria farmacêutica. sua funcionalidade é aumentada ainda mais por seu design, seja do tipo baioneta, braçadeira ou anel de trava, que acomoda uma variedade de requisitos operacionais e configurações de sistema.

Maximizar as vantagens dos Fechamentos Rápidos requer uma compreensão profunda de todas as suas complexidades, desde os seus fundamentos até ao seu funcionamento até aos sinais técnicos que determinam quais escolher. Com as informações corretas, a escolha do Fechamento Rápido ideal para uma determinada aplicação pode garantir máximo desempenho, segurança e longevidade.

Avaliações

Não há comentários ainda.