Descrição

Introdução de fechamentos de atuação rápida

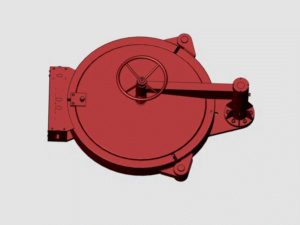

As tampas de atuação rápida oferecidas pela EMT fornecem uma solução robusta para vedação eficiente. Projetadas com foco na segurança e funcionalidade, essas tampas vêm equipadas com mecanismos de intertravamento e componentes opcionais que melhoram seu desempenho. Desde mecanismos de abertura e fechamento até braços giratórios e juntas curtas, essas tampas são projetadas para garantir um funcionamento suave, mantendo a integridade das tubulações. Com grande ênfase em recursos de segurança e design inovador, os fechamentos de atuação rápida são um componente indispensável para o gerenciamento eficaz de sistemas de dutos.

Os fechamentos de atuação rápida são um componente essencial em indústrias onde a eficiência operacional, a segurança e a acessibilidade às embarcações são cruciais. Seu design e recursos podem variar dependendo dos requisitos específicos da aplicação e dos padrões da indústria.

Principais recursos dos fechamentos de atuação rápida

- Abertura e fechamento rápidos: Esses fechamentos são projetados para serem operados rapidamente, muitas vezes em questão de minutos ou segundos, permitindo acesso eficiente ao conteúdo do recipiente.

- Mecanismos de segurança: Os fechos de atuação rápida normalmente incorporam recursos de segurança para evitar abertura ou fechamento acidental. Estes podem incluir mecanismos de travamento, intertravamentos e indicadores para garantir que o fechamento esteja devidamente protegido ou liberado.

- Pressão e vedação estanque: Quando fechados, esses fechos criam uma vedação estanque à pressão e à prova de vazamentos para manter a integridade do recipiente e evitar a liberação do conteúdo.

- Fácil de usar: Os fechos de atuação rápida são projetados para serem fáceis de usar e requerem o mínimo de ferramentas ou equipamentos especializados para operação.

- Variabilidade: Eles vêm em vários tamanhos e designs para acomodar diferentes tipos, tamanhos e classificações de pressão de vasos.

- Aplicativo: Eles são comumente usados para aplicações como pigging de dutos, inspeção, manutenção e limpeza de tanques, vasos e outros equipamentos que contenham pressão.

- Materiais: Esses fechos são normalmente construídos com materiais adequados ao conteúdo e às condições do recipiente, muitas vezes incluindo metais e elastômeros resistentes à corrosão.

Vantagens dos fechamentos de atuação rápida

- Operação rápida: Equipado com uma estrutura de anel de trava escalável integrada, nosso fecho de atuação rápida reduz drasticamente o tempo de operação em comparação com outros tipos de fechos de abertura rápida. Ele permite que um único operador conclua facilmente o processo de abertura e fechamento em um minuto, usando menos de 200N de força.

- Vedação aprimorada: Graças à nossa estrutura exclusiva de vedação labial auto-apertável, garantimos um processo de vedação mais seguro e confiável de fechamentos de atuação rápida.

- Sistema de trava de segurança: Our closure features a safety lock system with a self-locking function. This system ensures that all operational parts, including the quick-opening blind and the locking structure, are locked before pressurizing the equipment. Without the lock in the reserved position, the equipment cannot be pressurized. After depressurizing the equipment and before opening the blind flange cover, the system ensures complete pressure relief inside the container. This double pressure relief mechanism helps avoid safety issues due to incorrect operations.

Basic Parameters of Quick Actuating Closures

Customized Design Pig Launcher Receiver Bandlocking Quick Actuating Closures | |

Pressão de projeto | 1.6 MPa ~ 30 MPa |

Corrosion allowance | 2 mm |

Seismic fortification intensity | 7 graus |

Work medium | Oil, nature gas, water, ore pulp, etc. |

Horário de abertura | Dentro dos anos 60 |

Tipo de abertura | Verticais ou horizontais |

Este produto foi projetado para suportar uma ampla faixa de pressões, desde um mínimo de 1,6 MPa até um máximo de 30 MPa. Para levar em conta a degradação potencial ao longo do tempo, uma tolerância à corrosão de 2 mm foi considerada no projeto. Em termos de resiliência, foi construído para suportar intensidades de fortificação sísmica de até 7 graus, garantindo um desempenho robusto mesmo em condições desafiadoras.

The device is versatile with regard to the types of mediums it can work with. It’s suitable for use with oil, natural gas, water, and even ore pulp. In terms of operation, it’s designed for efficiency, with an opening time of less than 60 seconds. Furthermore, it offers flexibility in installation, accommodating both vertical and horizontal orientations.

Avaliações

Não há comentários ainda.