Descrição

Nas operações de limpeza de dutos, os acessórios de porquinhos desempenham um papel crucial na otimização do fluxo, na prevenção de corrosão e na limpeza dos bloqueios. Esses dispositivos versáteis, usados em conjunto com os porcos de limpeza de pipeline, estão equipados com vários componentes que aprimoram seus recursos de limpeza e permitem inspeção e manutenção eficientes. Neste artigo, exploraremos os principais acessórios de porquinhos, suas funções e os materiais dos quais são feitos.

Tipos de acessórios de porquinhos

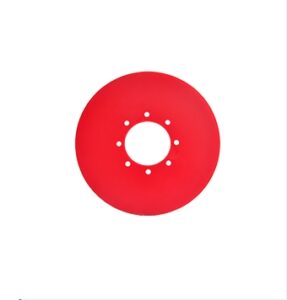

Disco de medição: Detecção precisa e eficiência de limpeza aprimorada

Um componente essencial dos acessórios de porcos é o disco de medição, localizado no meio do porco. Ele serve a vários propósitos, incluindo a detecção de deformações do pipeline e a melhoria da eficiência da limpeza. Normalmente feito de alumínio, o disco de medição é projetado para ter um diâmetro variando de 80% a 95% do diâmetro interno do tubo. Esse dimensionamento garante remoção eficaz da impureza e aprimora a eficiência geral da transmissão do pipeline. Além disso, o disco de medição ajuda a isolar diferentes meios, realizar testes de pressão e identificar a corrosão do pipeline.

Aço magnético: Absorção e manutenção da ferrugem

Outro acessório crítico é o aço magnético, geralmente criado a partir de material NDFEB, que possui a capacidade única de absorver a ferrugem dentro da tubulação. A acumulação de ferrugem é um problema comum nos pipelines de metal, levando a eficiência reduzida e danos potenciais. Ao incorporar aço magnético nos acessórios de porquinhos, torna -se possível mitigar esses problemas e manter um interior limpo.

Escova de aço: Limpeza completa do meio residual

As escovas de aço, geralmente feitas de aço carbono ou nylon, são empregadas como acessórios de porquinhos para enfrentar depósitos teimosos e meios residuais em pipelines. Esses pincéis são colocados na extremidade frontal do porco, oferecendo excelente eficácia de limpeza. A robustez do pincel de aço garante a remoção completa de detritos e contaminantes, contribuindo para melhorar o desempenho do pipeline.

Escova de aço de mola: Eficiência e flexibilidade de limpeza aprimoradas

A escova de aço da mola serve a um propósito semelhante ao pincel de aço padrão, mas com flexibilidade adicional. Construído usando materiais de aço carbono e nylon, a escova de aço da mola está estrategicamente posicionada nos acessórios de porquinhos. Essa configuração aumenta a eficácia da limpeza, acomodando curvas e curvas dentro do pipeline, garantindo a remoção ideal de resíduos e depósitos.

Corpo de aço carbono: Integridade estrutural e conectividade

O corpo de aço carbono forma a principal estrutura dos acessórios de porquinhos, garantindo a durabilidade geral e a conectividade dos componentes. Ao utilizar o aço carbono, que oferece excelente resistência e resistência à corrosão, os acessórios de porquinhos podem suportar as condições exigentes encontradas durante as operações de limpeza. O corpo de aço carbono está conectado ao copo, criando uma montagem resistente e confiável.

Disco -guia: Entrada suave e durabilidade prolongada

Feito de poliuretano, o disco -guia auxilia os acessórios de porquinhos durante a entrada de pipeline, fornecendo suporte e estendendo a distância de funcionamento. Esse acessório desempenha um papel crítico para garantir a inserção suave do porco no pipeline. Além disso, o disco -guia aumenta a durabilidade do disco frontal e do copo, aumentando a longevidade geral do porco.

Transmissor: Localização e rastreamento precisas de porco

O transmissor serve como um acessório essencial para operações de porquinhos. Sua função principal é transmitir sinais, permitindo rastreamento e localização precisos do porco dentro do pipeline. Ao incorporar um transmissor nos acessórios de porquinhos, os operadores podem monitorar com precisão o progresso do porco, garantindo cobertura abrangente e limpeza eficiente.

Copos: Componentes versáteis de poliuretano

Os copos, compostos de poliuretano, constituem os principais componentes dos acessórios de porquinhos. Esses elementos integrais fornecem a vedação e a tração necessárias para impulsionar o porco através do pipeline. O poliuretano oferece excelente resistência ao desgaste e durabilidade, permitindo que o porco atravesse o oleoduto de maneira suave e eficiente.

Vantagens

- Detecção precisa e eficiência de limpeza aprimorada: O disco de medição nos acessórios de porcos detecta deformações de pipeline e melhora a eficiência da limpeza, contribuindo para a eficiência geral da transmissão do pipeline.

- Absorção e manutenção da ferrugem: O aço magnético nos acessórios de porcos absorve a ferrugem dentro de oleodutos, atenuando a redução da eficiência e os possíveis danos causados pelo acúmulo de ferrugem.

- Limpeza completa do meio residual: Os escovas de aço efetivamente lidam com depósitos teimosos e mídia residual em pipelines, contribuindo para melhorar o desempenho do pipeline.

- Eficiência e flexibilidade de limpeza aprimoradas: O pincel de aço da mola oferece flexibilidade adicional, acomodando curvas e curvas dentro de oleodutos, garantindo a remoção ideal de resíduos e depósitos.

- Integridade estrutural e conectividade: O corpo de aço carbono garante a durabilidade geral e a conectividade dos acessórios de porquinhos, suportando as condições exigentes encontradas durante as operações de limpeza.

- Entrada suave e durabilidade prolongada: O disco -guia fornece suporte durante a entrada do pipeline, estendendo a distância de funcionamento e aumentando a durabilidade do disco frontal e do copo.

- Localização e rastreamento precisas de porco: O transmissor permite rastreamento e localização precisos do porco dentro do pipeline, garantindo cobertura abrangente e limpeza eficiente.

- Versatilidade e durabilidade: Os copos, compostos de poliuretano, fornecem a vedação e a tração necessárias para impulsionar o porco através do oleoduto enquanto exibem excelente resistência e durabilidade do desgaste.

Conclusão

No reino da manutenção do pipeline, o uso de acessórios de porquinhos é vital para limpeza, inspeção e manutenção eficazes. Discos de medição, aço magnético, escovas de aço, escovas de aço de mola, corpos de aço carbono, discos de guia, transmissores e copos contribuem para a eficiência geral e o sucesso das operações de porco.

Ao incorporar um disco de medição no design de acessórios de porquinhos, os operadores podem detectar deformações dentro do pipeline enquanto melhoram simultaneamente o processo de limpeza. O acessório de aço magnético desempenha um papel crucial na absorção de ferrugem, impedindo a corrosão e mantendo a integridade do oleoduto. As escovas de aço e as escovas de aço da mola removem efetivamente o meio residual e os depósitos, garantindo um interior de pipeline limpo e desobstruído.

O corpo de aço carbono fornece a integridade e a conectividade estruturais necessárias para os componentes dos acessórios de porquinhos, garantindo durabilidade e longevidade durante as operações de limpeza exigentes. Oriente os discos, feitos de poliuretano, facilitam a entrada lisa de porco na tubulação, aumentando a durabilidade do disco frontal e do copo do porco. Os transmissores permitem rastreamento e localização precisos, aumentando a eficiência operacional.

Os copos, os principais componentes dos acessórios de porquinhos, são criados a partir de poliuretano por sua versatilidade, resistência ao desgaste e durabilidade. Eles fornecem a vedação e a tração necessárias para impulsionar o porco através do oleoduto de maneira eficaz. Esses acessórios contribuem coletivamente para limpeza eficiente, eficiência de transmissão aprimorada, corrosão reduzida e segurança aprimorada nos pipelines.

Ao selecionar acessórios de porcos, é essencial considerar fatores como tamanho do pipeline, requisitos de limpeza e condições ambientais. Trabalhar com profissionais experientes e fornecedores respeitáveis pode fornecer orientações valiosas e garantir a seleção de acessórios adaptados a necessidades específicas de manutenção de pipeline.

Em conclusão, os acessórios de porcos são essenciais para alcançar a manutenção eficiente e completa do pipeline. O disco de medição, o aço magnético, as escovas de aço, as escovas de aço de mola, os corpos de aço carbono, os discos guia, os transmissores e os copos contribuem para a eficácia geral dos processos de porquinhos. Ao empregar esses acessórios e utilizar materiais de alta qualidade, os operadores podem garantir a limpeza, a integridade e a longevidade de seus oleodutos, levando a uma maior eficiência operacional e custos de manutenção reduzidos.

Lembre -se de que a manutenção e a inspeção regulares são essenciais para o desempenho e a longevidade ideais dos pipelines. Os oleodutos adequadamente limpos e mantidos contribuem para o transporte eficiente de fluidos, o tempo de inatividade reduzido e a segurança aprimorada.

Avaliações

Não há comentários ainda.