Descrição

Uma visão geral das juntas isoladas monolíticas

As juntas isoladas monolíticas desempenham um papel crucial na indústria de oleodutos, fornecendo isolamento elétrico entre as seções de um pipeline. Esses componentes especializados são essenciais para proteger os pipelines contra corrosão e correntes elétricas perdidas, o que pode levar a interferências e comprometer a integridade do pipeline.

No reino da infraestrutura de pipeline, garantir a segurança e a longevidade desses condutos vitais é de extrema importância. Para conseguir isso, é crucial implementar medidas eficazes que evitem danos causados por correntes elétricas e corrosão perdidas. Uma dessas medidas que desempenha um papel fundamental no isolamento eletrônico de várias seções do oleoduto é a utilização de juntas isoladas monolíticas. Neste artigo, nos aprofundaremos sobre o significado dessas juntas e sua capacidade de proteger a integridade do pipeline, além de destacar as vantagens que eles oferecem sobre soluções alternativas.

O que são juntas isoladas monolíticas?

São dispositivos especializados projetados para fornecer isolamento elétrico completo entre diferentes segmentos de um pipeline. Essas articulações atuam como barreiras, impedindo o fluxo de correntes elétricas perdidas e inibindo a corrosão galvânica que pode comprometer a integridade estrutural do pipeline. Ao isolar efetivamente as seções, essas juntas ajudam a proteger o oleoduto contra danos potenciais e garantir sua longevidade.

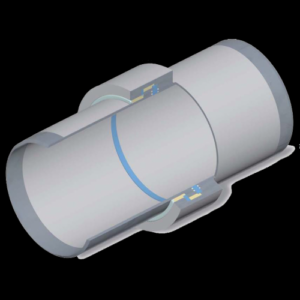

Construção e design

As juntas isoladas monolíticas são tipicamente construídas usando materiais duráveis que possuem excelentes propriedades isolantes elétricas. As juntas são projetadas para suportar as condições adversas encontradas em ambientes de tubulação, incluindo temperaturas extremas, altas pressões e substâncias corrosivas. Isso garante sua confiabilidade e longevidade, fornecendo uma solução robusta para isolar eletricamente seções de pipeline.

Funcionalidade e benefícios

A função primária das juntas isoladas monolíticas é impedir o fluxo de correntes elétricas entre diferentes segmentos da tubulação. Ao fazer isso, eles mitigam o risco de corrosão galvânica, o que pode levar a danos estruturais e vazamentos. Essas articulações atuam como pontos estratégicos de desconexão elétrica, garantindo que quaisquer correntes perdidas geradas no sistema de tubulações estejam contidas em suas respectivas seções. Essa segregação ajuda a manter a integridade do pipeline e minimiza o potencial de efeitos corrosivos.

Vantagens de juntas isoladas monolíticas

Segurança aprimorada

A implementação de juntas isoladas monolíticas aprimora significativamente a segurança das operações de pipeline. Ao isolar efetivamente seções, o risco de falhas elétricas, faíscas e incidentes perigosos é bastante reduzido. Isso é particularmente crucial nas indústrias onde substâncias inflamáveis ou perigosas são transportadas através de oleodutos.

Proteção contra corrosão

A corrosão representa uma ameaça severa à integridade e à vida útil dos oleodutos. As juntas isoladas monolíticas fornecem um mecanismo de defesa eficaz contra a corrosão, eliminando ou reduzindo significativamente o acoplamento galvânico entre materiais diferentes. Ao interromper o caminho elétrico entre os segmentos, essas juntas mitigam as reações eletroquímicas que iniciam processos de corrosão, protegendo a longevidade do oleoduto.

Flexibilidade operacional

A implementação de juntas isoladas monolíticas oferece flexibilidade operacional, permitindo a instalação de sistemas de proteção catódica em seções individuais de pipeline. A proteção catódica é uma técnica de prevenção de corrosão amplamente utilizada que utiliza uma corrente elétrica externa para combater as forças corrosivas. Ao isolar segmentos, as juntas isoladas monolíticas permitem a aplicação independente de métodos de proteção catódica, otimizando as medidas de controle de corrosão em toda a rede de oleodutos.

Economia de custos a longo prazo

Investir em juntas isoladas monolíticas pode gerar economia de custos a longo prazo para os operadores de tubulação. Ao minimizar o risco de danos relacionados à corrosão, a necessidade de reparos frequentes, manutenção e substituição de seções de tubulação é significativamente reduzida. Isso leva a custos operacionais mais baixos, maior eficiência e melhor gerenciamento geral de ativos.

Chaves de atributo de juntas isoladas monolíticas

Junta isolante, composto dielétrico e tinta epóxi não condutiva

As juntas isoladas monolíticas são projetadas com uma junta isolante que impede o contato de metal a metal entre as seções do pipeline. As cavidades internas dentro dessas juntas são preenchidas com um composto dielétrico, que ajuda no isolamento elétrico. Além disso, as superfícies internas e externas da articulação são revestidas com tinta epóxi não condutiva para melhorar ainda mais as propriedades isolantes.

Projeto e fabricação de juntas isoladas monolíticas por EMT

Construção sem parafuso, de peça única e personalização

As juntas isoladas monolíticas da EMT apresentam uma construção sem parafuso e de peça única, simplificando a instalação e garantindo uma conexão robusta e à prova de vazamentos. Essas juntas são fabricadas em conformidade com as especificações da tubulação do cliente e podem incluir filhotes de tubo extra comprimento como um recurso opcional, se necessário.

Fadiga de pressão, torção, teste de prova de flexão e Garantia de qualidade

Para garantir a confiabilidade e a longevidade das articulações, os sujeitam a fadiga da pressão, a torção e os testes à prova de flexão. Técnicas de exame não destrutivas e relatórios de teste também são empregados para verificar a qualidade e o desempenho das juntas durante e após a produção.

Assembléia da fábrica e teste hidrostático

Antes de serem enviados ao cliente, as juntas isoladas monolíticas da EMT passam por montagem de fábrica e testes hidrostáticos. Isso garante que as juntas atendam às especificações necessárias e estejam prontas para integração perfeita no sistema de pipeline.

Capacidade de isolamento e manutenção de juntas isoladas monolíticas

Teste elétrico, verificação e operação sem manutenção

A capacidade isolante das juntas isoladas monolíticas da EMT é verificada através de rigoroso teste elétrico. Uma vez instalados, essas juntas fornecem uma vida útil sem manutenção, reduzindo os custos operacionais e garantindo a segurança do sistema de pipeline.

Termos diferentes usados na indústria de oleodutos

As juntas isoladas monolíticas também são referidas como juntas de isolamento ou juntas isolantes na indústria de oleodutos. Embora a terminologia possa variar, o objetivo e a funcionalidade desses componentes permanecem consistentes no fornecimento de isolamento e proteção elétrica contra corrosão e interferência.

Produtos adicionais oferecidos pela EMT

Além das juntas isoladas monolíticas, a EMT também oferece uma variedade de outras soluções de pipeline, incluindo fechamentos de abertura rápida, fechamentos no estilo de garfo, sinalizadores de porco, e assim por diante. Esses produtos foram projetados para melhorar a eficiência, a segurança e a confiabilidade do seu sistema de pipeline. Para obter mais informações sobre a gama abrangente de produtos de pipeline da EMT, visite nosso site ou entre em contato conosco diretamente.

Perguntas freqüentes sobre juntas isoladas monolíticas

Q1: Qual é o objetivo da indústria de oleodutos?

A1: As juntas isoladas monolíticas fornecem isolamento elétrico entre as seções de uma tubulação, protegendo contra a corrosão e as correntes elétricas perdidas que podem comprometer a integridade do pipeline.

P2: Quais são os principais atributos disso?

A2: Eles são projetados com uma junta isolante para evitar o contato de metal a metal entre as seções do pipeline. Eles são preenchidos com um composto dielétrico para isolamento elétrico e revestidos com tinta epóxi não condutiva para melhorar o isolamento.

Q3: Como ele foi projetado e fabricado pela EMT?

A3: as juntas isoladas monolíticas da EMT apresentam uma construção sem parafuso e sem parafuso para facilitar a instalação e uma conexão à prova de vazamentos. Eles são personalizados de acordo com as especificações da tubulação e podem incluir filhotes de tubo extra de comprimento, se necessário.

Q4: Quais medidas de garantia de qualidade são empregadas durante a produção de juntas isoladas monolíticas?

A4: A EMT sujeita as juntas para a fadiga de pressão, a torção e os testes à prova de flexão para garantir confiabilidade e longevidade. Técnicas de exame não destrutivas e relatórios de teste são utilizados para verificar a qualidade e o desempenho das juntas.

Q5: Como é testado e preparado antes da integração no sistema de pipeline?

A5: O EMT realiza montagem de fábrica e testes hidrostáticos nas juntas isoladas monolíticas para garantir que elas atendam às especificações necessárias. Isso garante que eles estejam prontos para integração perfeita no sistema de pipeline.

Avaliações

Não há comentários ainda.