Descrição

Compreendendo a válvula DBB

Uma válvula Double Block and Bleed (DBB) é um tipo específico de válvula usada principalmente na indústria de petróleo e gás, mas também em várias outras aplicações industriais. O principal objetivo de uma válvula DBB é interromper o fluxo de fluido e garantir o isolamento completo do fluido em um sistema.

Tipos de válvulas DBB

Na verdade, as válvulas DBB vêm em dois designs principais: o tipo de corpo modular ou dividido e o tipo integral. Compreender os recursos e aplicações exclusivos de cada projeto ajudará você a selecionar a melhor válvula DBB para suas necessidades.

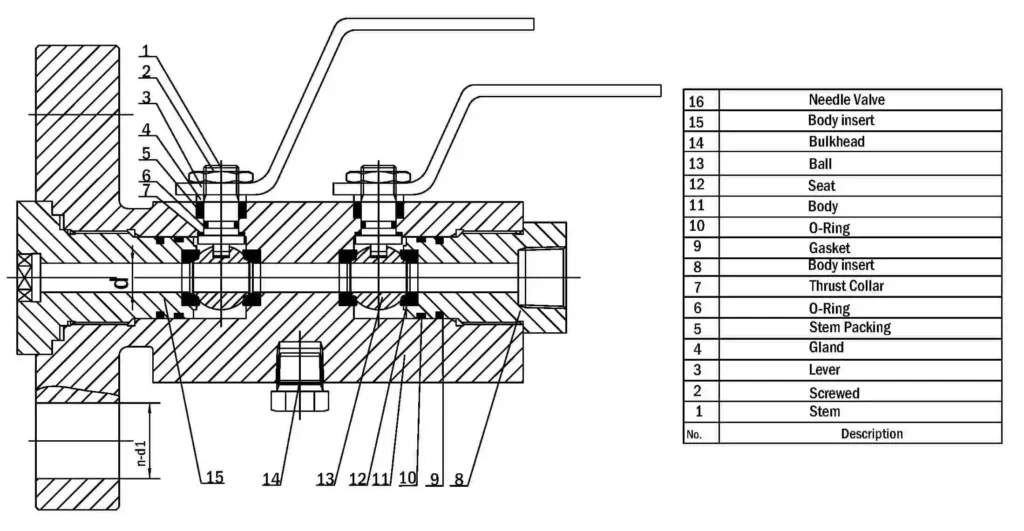

- Válvula DBB tipo corpo modular ou dividido: Este design caracteriza-se pela sua estrutura de esfera dupla, proporcionando uma camada extra de segurança. A presença de duas esferas em um único corpo de válvula garante duplo bloqueio, característica crítica em aplicações de alto risco. Um componente chave deste projeto é a válvula agulha de drenagem, estrategicamente situada entre as duas esferas. Esta válvula facilita a drenagem da válvula, permitindo que a pressão seja zerada quando necessário. A modularidade deste projeto, facilitada pela construção do corpo em três peças, torna-o versátil e benéfico para inúmeras aplicações, incluindo instrumentação e tubulação. Essas válvulas vêm em uma variedade de tamanhos, variando de 1 a 24 polegadas, e podem lidar com uma variedade de classificações de classes de pressão, de API 3.000 a API 10.000, e em todas as pontuações de classes de pressão de 150 a 2.500 lbs.

- Válvulas DBB integrais: Essas válvulas, utilizadas principalmente na indústria de instrumentação, vêm em uma infinidade de designs para atender a uma ampla gama de necessidades. Os projetos incluem flange a flange, flange a rosca, injeção e amostragem e tipos de esfera e agulha, oferecendo flexibilidade para diversas aplicações industriais. Semelhante ao tipo de corpo modular ou dividido, o DBB Integral também possui uma válvula agulha de drenagem posicionada entre as duas esferas. Isto permite a drenagem da válvula e a reposição da pressão para zero quando necessário. O design integral é conhecido por sua construção robusta e pela capacidade de lidar com a pressão com eficiência.

Como escolher a válvula DBB certa

A seleção da válvula Double Block and Bleed (DBB) apropriada para suas necessidades requer um conhecimento completo da aplicação, do tipo de meio que está sendo controlado e das condições operacionais, especialmente temperatura e pressão. Vamos nos aprofundar em cada um desses fatores:

- Natureza da Aplicação: Os requisitos específicos da sua aplicação desempenham um papel fundamental na determinação da válvula DBB apropriada. Por exemplo, se você precisar manter a integridade de um sistema enquanto repara uma seção da tubulação, uma válvula DBB pode fornecer o isolamento necessário. Nesse cenário, você pode empregar duas válvulas de gaveta para bloquear o fluxo onstream. Enquanto isso, uma válvula esférica pode ser utilizada para liberar o fluido da seção bloqueada da tubulação, permitindo que os reparos ocorram com segurança. Compreender as complexidades de sua aplicação pode orientá-lo em direção ao tipo e configuração de válvula DBB mais adequados.

- Tipo de meio: O tipo de meio, ou meio, que você pretende controlar também influencia bastante a seleção de uma válvula DBB. Para controlar líquidos viscosos e gases densos, por exemplo, você pode precisar de uma válvula esférica, globo ou gaveta de passagem total como válvula de bloqueio devido à sua capacidade de lidar com esses tipos de meios. Uma válvula agulha, conhecida por sua precisão, é frequentemente escolhida como válvula de sangria em tais situações. No caso de meios corrosivos, pode ser necessário optar por válvulas DBB em aço inoxidável, que oferecem excelente resistência à corrosão, garantindo o bloqueio eficaz do meio sem causar danos à própria válvula.

- Condições operacionais de temperatura e pressão: As condições sob as quais sua operação é realizada também afetarão a escolha da válvula DBB. Aplicações de alta pressão e alta temperatura podem exigir o uso de válvulas de esfera antiestáticas como válvulas de bloqueio. Esses tipos de válvulas são projetados para suportar flutuações de pressão e vibrações, tornando-as seguras para uso em operações sensíveis. Em contraste, as operações de baixa pressão podem ser mais adequadas para uma única válvula gaveta DBB com cunhas ajustáveis e uma válvula de purga do corpo, que pode oferecer a funcionalidade necessária sem a necessidade de resistência a alta pressão.

Ao considerar estes fatores – a natureza da aplicação, o tipo de meio e as condições operacionais – você pode tomar uma decisão informada ao selecionar uma válvula DBB, garantindo que ela atenderá às suas necessidades específicas e contribuirá para a operação segura e eficiente do seu sistema.

Vantagens de usar válvulas DBB

As válvulas Double Block and Bleed (DBB) são engenhosamente projetadas para substituir o método tradicional de unir válvulas individuais para obter isolamento duplo. Este design simplificado oferece vários benefícios significativos:

- Espaço, peso e eficiência de instalação: As válvulas DBB consolidam múltiplas funções de válvula em uma única unidade, levando a economias substanciais em termos de peso e espaço – até 60% em alguns casos. Este design compacto é especialmente vantajoso para instrumentos isolantes ou gaiolas de instrumentos. Além disso, ao simplificar o número de componentes a serem instalados, as válvulas DBB também podem reduzir o tempo de instalação em até 70%.

- Segurança Ambiental: Uma das principais vantagens das válvulas DBB é o seu potencial para minimizar o impacto ambiental. Ao reduzir significativamente o número de possíveis caminhos de vazamento, as válvulas DBB diminuem a probabilidade de vazamentos perigosos, aumentando a segurança geral de suas operações.

- Segurança de Manutenção: Quando é necessário realizar tarefas de manutenção após a primeira válvula de isolamento, o isolamento duplo é crucial. As válvulas DBB atendem perfeitamente a esse requisito. Eles apresentam uma válvula de ventilação esférica ou globo que permite a ventilação segura da pressão presa entre as duas válvulas de isolamento.

- Versatilidade e funções adicionais: As válvulas DBB evoluíram para incluir funções adicionais, como injeção de produtos químicos e pontos de amostragem, aumentando ainda mais sua utilidade. Alguns projetos integram até válvulas de controle, tornando essas válvulas multifuncionais uma escolha versátil para diversas aplicações.

Em essência, as válvulas DBB são um divisor de águas na indústria de válvulas, oferecendo economias substanciais em peso, espaço e tempo de instalação, melhorando a segurança ambiental, fornecendo recursos de segurança cruciais para manutenção e ostentando versatilidade com funções adicionais.

Indústrias e aplicações para válvulas DBB

As válvulas Double Block and Bleed (DBB), conhecidas por sua versatilidade e recursos de segurança, encontram aplicações em uma ampla gama de indústrias. Na indústria de petróleo e gás, por exemplo, as válvulas DBB são essenciais para o isolamento durante a manutenção ou para a liberação segura de gases e líquidos. Da mesma forma, na indústria petroquímica, eles são usados por suas capacidades de isolamento eficazes, especialmente no manuseio de fluidos perigosos. A indústria química também se beneficia do uso de válvulas DBB, onde garantem a contenção segura e a liberação controlada de produtos químicos agressivos. Em usinas de geração de energia, as válvulas DBB são frequentemente usadas para gerenciar sistemas de alta pressão com segurança. Também encontram aplicações em estações de tratamento de água, onde auxiliam na regulação da vazão e no isolamento de trechos para manutenção. Em resumo, as válvulas DBB são utilizadas sempre que há necessidade de uma solução compacta que ofereça isolamento duplo e função de purga para garantir uma operação segura.

Válvulas DBB vs. Válvula DIB

- Válvula de duplo bloqueio e purga (DBB): Uma válvula DBB possui essencialmente duas superfícies de vedação ou mecanismos (blocos) que podem isolar o fluxo do meio (como gás ou líquido). A função de “sangramento” é um recurso adicional que permite que a pressão retida entre esses dois blocos seja liberada ou “sangrada” com segurança, se necessário. Isto geralmente é conseguido através de uma válvula de ventilação ou drenagem na cavidade do corpo da válvula. As válvulas DBB são utilizadas em aplicações críticas onde o vazamento pode ter consequências graves, sendo necessário garantir o isolamento completo do meio.

- Válvula de duplo isolamento e purga (DIB): Uma válvula DIB também possui duas superfícies de vedação, semelhantes a uma válvula DBB, mas com uma diferença importante. Em uma válvula DIB, ambas as superfícies ou mecanismos de vedação são projetados para serem bidirecionais, ou seja, podem bloquear o fluxo do meio em qualquer direção (a montante ou a jusante). A função de “sangramento” é a mesma de uma válvula DBB – ela permite que a pressão retida entre os dois blocos seja liberada com segurança. Esse recurso bidirecional torna as válvulas DIB adequadas para aplicações onde a direção do fluxo pode mudar ou onde é necessário isolamento em ambos os lados da válvula.

Resumo

As válvulas Double Block and Bleed (DBB), disponíveis em designs modulares e integrais, são essenciais em vários setores, incluindo petróleo e gás, petroquímico e geração de energia. Essas válvulas fornecem isolamento duplo e função de purga, garantindo o fechamento completo do fluxo de fluido e maior segurança durante tarefas de manutenção. A seleção de uma válvula DBB adequada depende da natureza da aplicação, do tipo de meio a ser controlado e das condições operacionais. As válvulas DBB oferecem benefícios significativos, como economia de espaço e peso, segurança ambiental, segurança de manutenção e funcionalidade adicional. Elas diferem das válvulas de duplo isolamento e sangramento (DIB) porque as válvulas DIB fornecem isolamento bidirecional.

Avaliações

Não há comentários ainda.