Descrição

Introdução

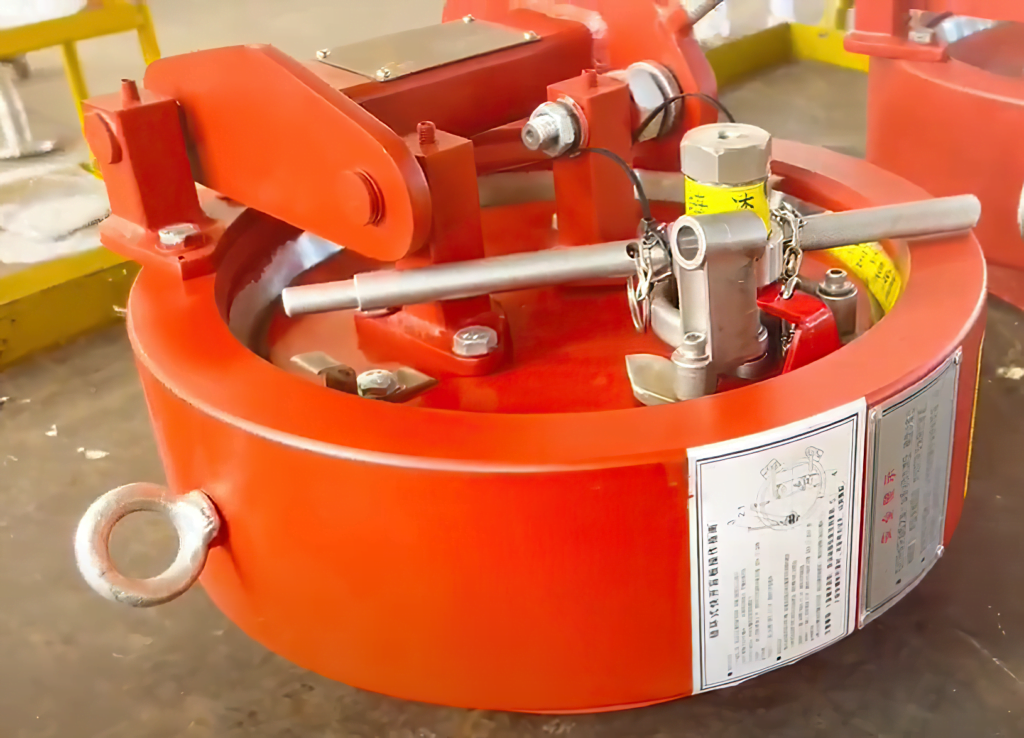

O fechamento rápido de abertura do EMT Bandlock, fabricado pela EMT, é um dispositivo mecânico altamente especializado que fornece acesso rápido e seguro a vasos de pressão e pipelines. Seu recurso exclusivo é sua operação rápida, capaz de abrir ou fechar qualquer tamanho de unidade em menos de um minuto sem o requisito de ferramentas especiais. Essa capacidade de fornecer acesso horizontal ou vertical aos vasos de pressão o torna uma ferramenta indispensável em aplicações de alta pressão, especialmente em tubulações de transmissão de petróleo e gás.

O design do fechamento rápido de abertura do Bandlock é uma prova da inovação, empregando tecnologia auxiliada por computador para obter uma estrutura leve e robusta. O design inclui um anel de impulso cônico de aço inoxidável duplex ou 'Bandlock', que distribui uniformemente a carga de pressão em torno da circunferência completa de 360 ° do cubo. Além disso, ele incorpora medidas extensas de segurança, incluindo um parafuso de aviso de pressão manual e intertravamentos de chave mecânica opcionais. Com uma ampla gama de tamanhos, temperatura e capacidades de pressão e configurações, o fechamento rápido de abertura da Bandlock mantém um padrão notável de eficiência e segurança no setor.

Recursos de design do fechamento de abertura rápida do Bandlock

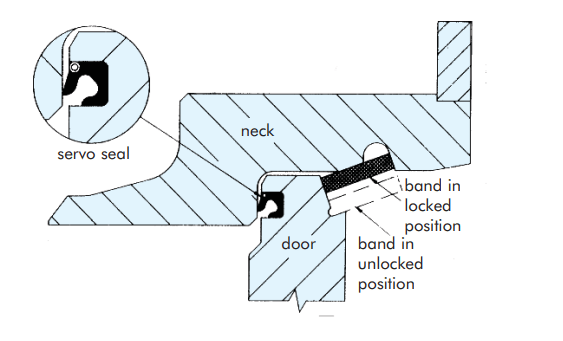

Selo do fechamento rápido de abertura do Bandlock

O fechamento de abertura rápida do Bandlock utiliza um vedação labial de dois gumes, especialmente criada e criada por pressão zero. O rosto da porta abriga esse design exclusivo, oferecendo proteção e garantindo uma vida útil mais longa. A moldagem inovadora de uma peça do selo permite uma instalação simples sem o uso de ferramentas especializadas. Ele vem em uma variedade de elastômeros e possui uma mola de aço inoxidável para garantir a capacidade total de vácuo e evitar a extrusão em circunstâncias de alta pressão. Surpreendentemente adaptável, esse design de vedação de uma peça funciona bem em aplicações horizontais e verticais.

Outra característica notável do fechamento rápido de abertura da banda é o material de vedação. O nitrilo com dureza em terra de 75 graus é o material usual de vedação. Viton, fluorocarbono explosivo resistente à descompressão e selos HNBR são outras alternativas. Dependendo do elastômero específico utilizado, o selo pode tolerar uma ampla faixa de temperatura de -58 a +392 graus Fahrenheit. A resiliência e a eficácia do selo em uma variedade de circunstâncias operacionais são garantidas pelo estudo cuidadoso de materiais e design.

O fechamento do Lock Bandlock EMT oferece acesso instantâneo a vasos de pressão, como armadilhas de porcos, filtros, coalesces, separadores e muito mais, acomodando posições horizontais e verticais. Sua velocidade operacional supera outros fechamentos rápidos de abertura. O design, aprimorado usando técnicas auxiliadas por computador, garante uma estrutura eficiente em termos de peso através do uso de análise de elementos finitos e teste de prova de cotonete, em conformidade com os códigos de vasos de pressão principal. O apelido do dispositivo, 'Bandlock', vem de seu mecanismo de travamento confiável - um anel de empuxo cônico de aço inoxidável duplex colocado entre a porta e o pescoço, que distribui uniformemente cargas em todo o perímetro de 360 ° do pescoço.

Manutenção do fechamento rápido de abertura do Bandlock

- Comece com uma inspeção visual do exterior do fechamento. Procure qualquer mancha de superfície, sinais de deformação nos componentes, parafusos ou parafusos soltos e limpeza geral.

- Prossiga para desbloquear e abra o fechamento e remova a vedação da porta. Examine o selo para qualquer dano. Se estiver danificado, substitua -o; Caso contrário, certifique -se de remover minuciosamente qualquer óleo ou outros contaminantes. A vida útil do selo é tipicamente um ano.

- Inspecione a ranhura do anel de vedação para qualquer ferrugem ou sujeira. Se for encontrado, use lixa ou pano de emery para limpá-lo meticulosamente, seguido de uma limpeza com um pano de algodão limpo.

- Examine a superfície de contato entre a porta e o anel de trava. Se estiver sujo, certifique -se de limpá -lo.

- Verifique a superfície interna do flange para qualquer sujeira ou ferrugem. Se estiver presente, limpe -o usando lixa e limpe -o com um pano de algodão limpo. Preste atenção especial à ranhura do anel de trava, pois tende a acumular sujeira, o que pode prejudicar a instalação do anel de trava.

- Olhe sobre a superfície de vedação para qualquer dano mecânico ou corrosão. Se necessário, faça um polimento para corrigi -lo.

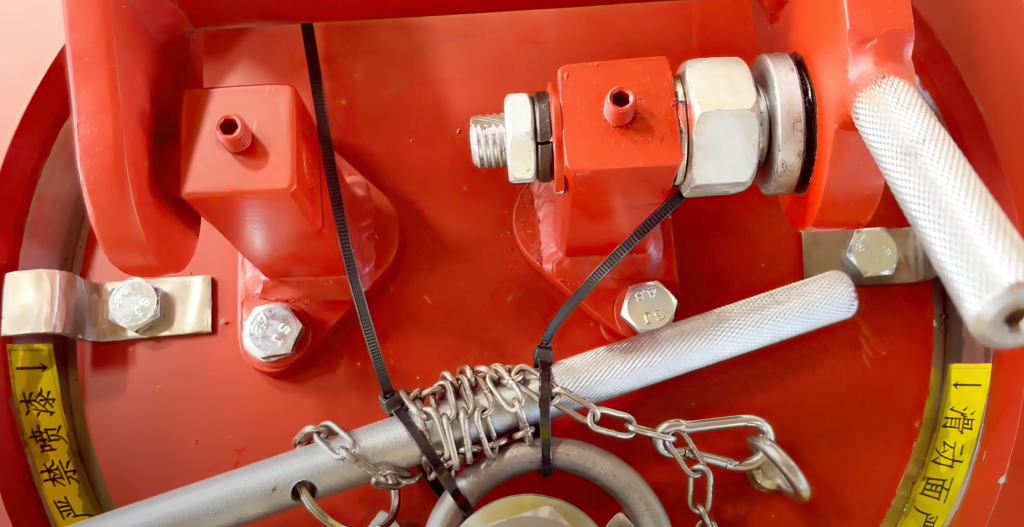

- Após o processo de limpeza, aplique o lubrificante na ranhura de vedação, a ranhura da correia de trava, a superfície de vedação, o anel de trava e a superfície de contato do anel de trava e da porta. Certifique -se de espalhar uma camada fina e uniforme de graxa.

- Examine a junta do parafuso de aviso de pressão para qualquer dano. Se estiver danificado, substitua -o. Caso contrário, limpe a junta e o orifício do parafuso e aplique uma pequena quantidade de lubrificante.

- Ao instalar o selo, esteja atento à direção. Inicie a instalação nas posições das 12:00, 3:00, 6:00 e 9:00 e pressione no perímetro.

- Por fim, aplique lubrificante a qualquer outra peças em movimento ou rotação para garantir uma operação suave.

Considerações de segurança para o fechamento rápido de abertura do Bandlock

Um forte sistema de segurança está incluído no fechamento rápido de abertura do Bandlock para garantir operações seguras em vários cenários. No entanto, o uso desse fechamento carrega possíveis perigos que devem ser gerenciados corretamente, assim como qualquer sistema mecânico operando sob extrema pressão. A seguir, são apresentadas algumas sugestões de segurança:

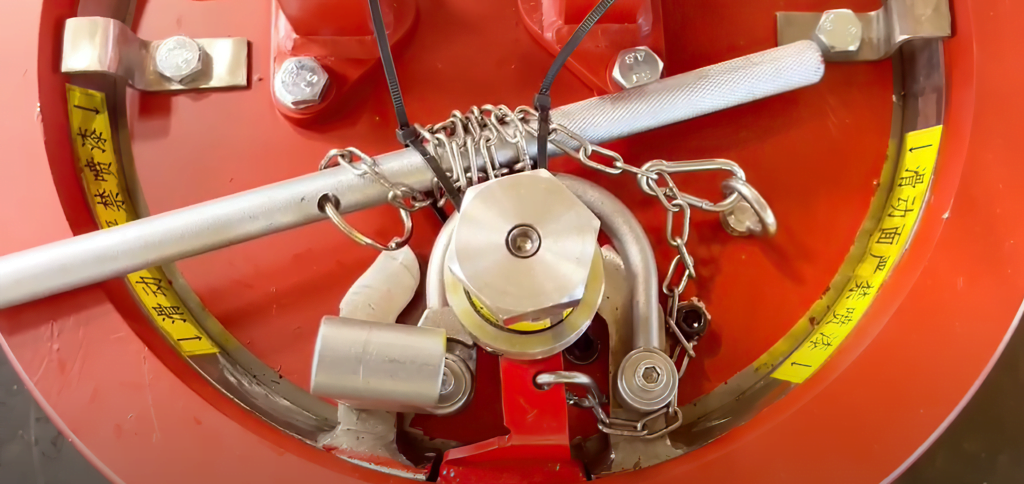

- Gerenciamento de pressão: O risco mais crítico associado ao fechamento rápido de abertura do Bandlock é o potencial de liberação repentina de pressão interna. O fechamento foi projetado com um parafuso de aviso de pressão, que impede que a porta seja desbloqueada até que toda a pressão interna seja aliviada, impedindo a liberação acidental de pressão. Os operadores devem sempre verificar se a pressão está totalmente aliviada antes de tentar abrir o fechamento.

- Sele Integrity: Um selo comprometido pode levar a vazamentos, o que pode ser potencialmente perigoso. Manutenção regular, inspeção e substituição do selo quando necessário são cruciais para manter a integridade do fechamento.

- Dano mecânico: Qualquer dano mecânico ao fechamento pode comprometer seu desempenho e segurança. Inspeções regulares para sinais de desgaste, corrosão e outros danos podem ajudar a garantir que quaisquer problemas em potencial sejam abordados antes que eles se tornem problemas significativos.

- Instalação e operação adequadas: A instalação incorreta ou operação do fechamento pode levar a riscos de segurança. Os operadores devem ser treinados adequadamente nos procedimentos corretos para instalar, operar e manter o fechamento rápido de abertura do Bandlock.

- Fatores ambientais: A operação do fechamento pode ser afetada por condições ambientais, como temperaturas extremas. O fechamento rápido de abertura do Bandlock foi projetado para operar dentro de uma ampla faixa de temperatura, mas é importante garantir que não seja submetido a condições fora dessa faixa.

Teste hidrostático

Os testes hidrostáticos são normalmente conduzidos como parte do exame final abrangente do vaso. No entanto, se houver necessidade de um teste hidrostático de fechamento individual, isso pode ser organizado por uma taxa adicional.

Conclusão

O fechamento rápido de abertura do EMT Bandlock é uma presença inovadora na arena de vasos de pressão e tecnologia de pipeline, velocidade de mistura, segurança e versatilidade em um design único. Esse fechamento, com seu novo vedação labial de dois gumes de servo-ação, opera com eficiência sob pressão zero nas aplicações horizontal e vertical. Seus selos, feitos principalmente de nitrila com uma dureza em terra de 75 °, exibem resiliência e durabilidade em um amplo espectro de temperatura, com alternativas disponíveis para requisitos industriais específicos.

O parafuso de aviso de pressão do fechamento rápido do fechamento de abertura da banda e os intertravamentos mecânicos opcionais servem como pistas visuais de que a segurança é uma prioridade superior no design. Isso permite operações seguras e o torna essencial em situações de alta pressão, como oleodutos de transmissão de petróleo e gás. Juntamente com um protocolo de manutenção completo. Sua versatilidade é ainda demonstrada pela opção para testes hidrostáticos individuais. Assim, o fechamento rápido de abertura do EMT Bandlock é um monumento aos resultados incríveis que podem ser alcançados quando a segurança, a eficácia e o design inovador se reúnem.

Avaliações

Não há comentários ainda.