Aqui está uma breve introdução aos diferentes tipos de porcos encanadores fornecido pela EMT (ou comumente encontrado em operações de manutenção e limpeza de dutos):

1. Porcos fundidos sólidos

- Descrição: Feito de poliuretano ou outro material durável.

- Usar: Ideal para limpeza, dosagem e medição.

- Características: Nenhuma peça móvel, resistente ao desgaste e à corrosão, pode lidar com detritos moderados.

2. Porcos ABS

- Descrição: Porcos com Acrilonitrila Butadieno Estireno (ABS) componentes, frequentemente usados em combinação com outros materiais.

- Usar: Adequado para limpeza geral e preparação de inspeção.

- Características: Leve, resistente a impactos e econômico.

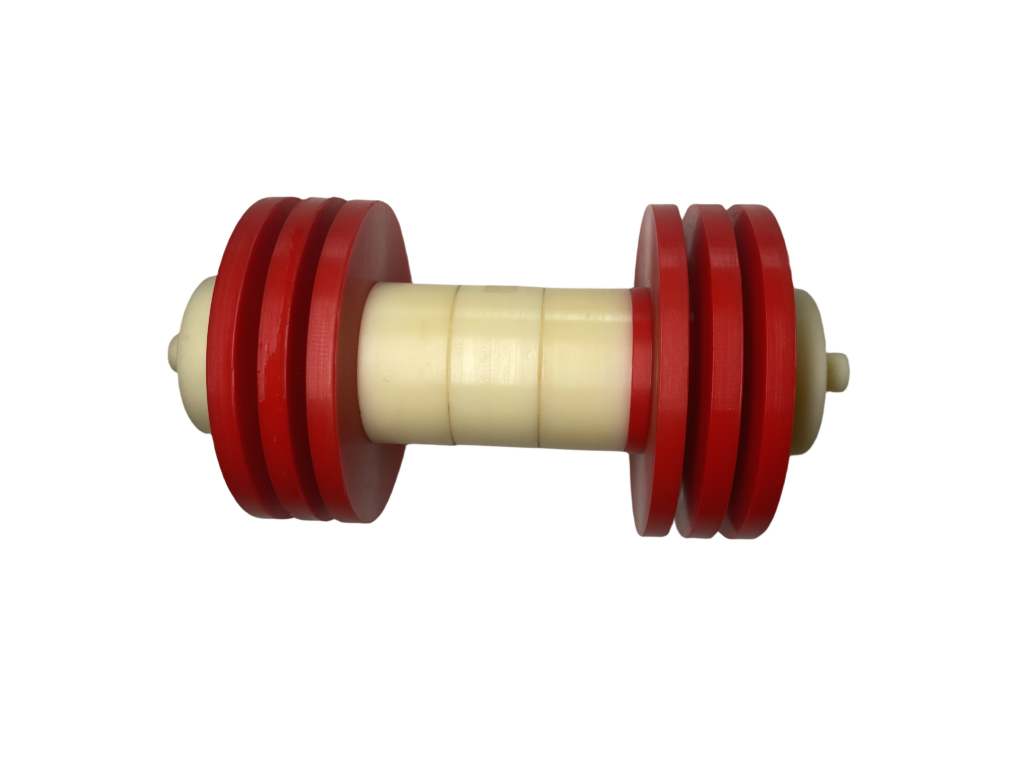

3. Xícara de Porcos

- Descrição: Apresentam copos flexíveis (geralmente de poliuretano) que formam vedações contra a parede do tubo.

- Usar: Usado para limpeza, remoção de líquidos e separação.

- Características: Vários copos podem ser adicionados para melhor vedação e capacidade de raspagem.

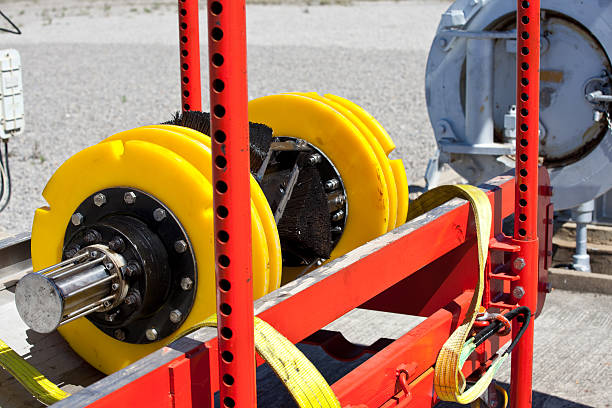

4. Porcos de disco

- Descrição: Semelhante a cup pigs, mas use discos planos ou côncavos em vez de xícaras.

- Usar: Excelente para raspagem e limpeza de tubulações.

- Características: Menor atrito do que cup pigs, adequado para percursos de longa distância e fluxos de alta velocidade.

5. Porcos de espuma

- Descrição: Feito inteiramente de espuma de células abertas ou fechadas, às vezes revestida com poliuretano.

- Usar: Usado para secar, limpar e drenar tubulações.

- Características: Leve, flexível, pode navegar facilmente por curvas e alterações de diâmetro.

6. Porcos Bola

- Descrição: Porcos esféricos feitos de materiais sólidos ou infláveis, como borracha ou espuma.

- Usar: Normalmente usado para remoção de líquidos ou separação de produtos.

- Características: Design simples, pode fluir com o produto, frequentemente utilizado em gasodutos.