Description

Introduction

Clamp Type Quick Open Closure

Clamp Type Quick Open Closures stand out among the various varieties of Quick Open Closures for their ease of use, dependability, and speed. To quickly and securely open and close the vessel, they use a clamping mechanism. Clamp Type Quick Closures are a favored option for industries requiring frequent access to vessel interiors because they are enhanced with safety elements to prevent inadvertent opening under pressure.

Quick Open Closures, which provide a safe and effective way to seal and access pressure vessels, tanks, and pipelines, are crucial parts of industrial operations. By allowing quick access for routine inspections and cleaning and eliminating the time-consuming procedure of unscrewing standard closures, these devices considerably increase operational efficiency and safety.

Understanding Clamp Type Quick Open Closures

Specialized tools called clamp-type quick closures are used in a variety of industrial applications to allow safe and quick access to pressure vessels, tanks, or pipeline interiors. These closures’ distinctive clamping mechanism provides a strong seal when closed while permitting quick and simple access when required.

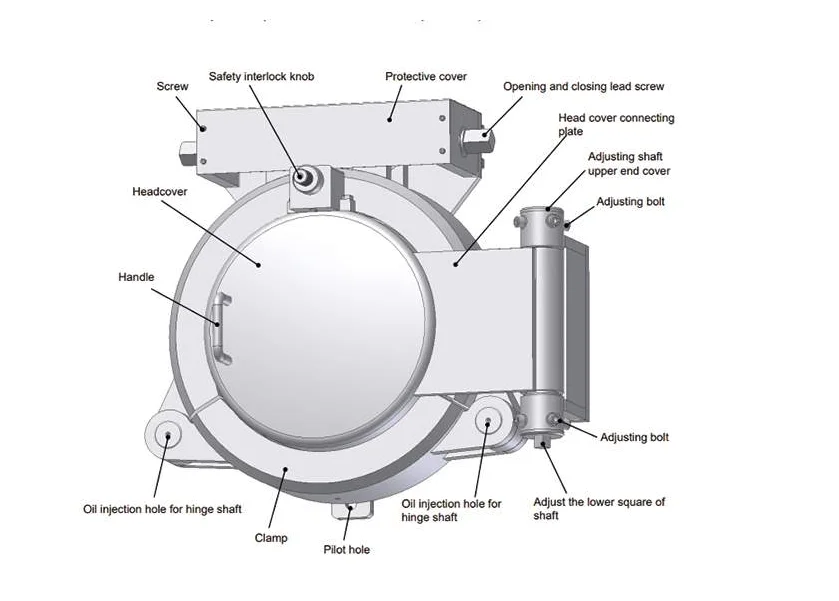

A door, a clamp or collar, and frequently a safety device make up a Clamp-type Quick Open Closure. The door, which is often circular, is made to fit snugly over a vessel’s aperture. After swinging over the door and being tightened, the clamp or collar, which is typically a hinged device, creates a high-pressure seal. To avoid the closure accidentally being released while the vessel is still under pressure, the safety mechanism is essential.

Clamp Type Quick Open Closures are very simple to use. When access to the vessel’s interior is required, the safety mechanism is removed first, followed by the clamp being loosened and swung away. The door can then be opened, allowing full access to the vessel’s interior. After completing the required activities, the door is closed, the clamp is swung back over the door and tightened, and the safety mechanism is re-engaged.

Advantages of Clamp Type Quick Open Closure

- Efficiency: Clamp Type Quick Closures minimize the time required to reach the interiors of vessels or pipelines significantly. They need less manual labor and time to open and close than typical bolted closures, enhancing operating efficiency.

- Safety: Safety elements are frequently included in these closures to avoid accidental opening under pressure. This is a significant advantage in companies that frequently work with pressured vessels.

- Ease of Use: Clamp Type Quick Open Closures are designed for ease of use. Their operation does not necessitate specialist knowledge or tools, making them user-friendly.

- Durability: These closures are typically strong and built to last in severe industrial situations. They are more resistant to wear and tear, resulting in fewer maintenance costs and a longer operational life.

- Versatility: Clamp Type Quick Closures have a wide range of uses, from the oil and gas industries to food processing and pharmaceuticals. This broad applicability is a significant benefit.

- Reduced Downtime: These closures help decrease downtime during maintenance and inspection activities by allowing quick and easy access to the interior of vessels and pipelines.

- Sealing Integrity: The design of Clamp-type closures assures a high-integrity seal, preventing leaks and maintaining the vessel or pipeline’s pressure integrity. They are well-suited to high-pressure and high-temperature applications.

Applications of Clamp Type Quick Open Closure

- Oil and Gas Industry: Clamp-type Quick Open Closures are commonly used in the oil and gas industry for pipelines, pig launchers and receivers, and pressure vessels. They are essential for frequent maintenance, inspection, and cleaning chores within various applications because of the quick access they allow.

- Chemical Processing: Because these closures can endure high pressures and temperatures while maintaining a strong seal, they are ideal for use in chemical reactors and storage tanks. They enable quick access during routine inspections or while responding to emergencies.

- Power Generation: Clamp-type Quick Open Closures are used to seal access points in power plants, particularly those that use pressurized systems such as steam boilers. They enable quick access during maintenance or outages, reducing downtime.

- Food and Beverage Industry: These closures are used in big food processing containers in the food and beverage industry. They allow for quick access to frequent cleaning and sanitation, assisting in the maintenance of good hygiene standards.

- Pharmaceutical Industry: Clamp-type Quick Open Closures enable secure sealing and quick access for inspection and cleaning in sterilizers, reactors, and other pressured equipment used in pharmaceutical manufacturing.

- Water Treatment Plants: In filtration systems, these closures provide for easy access for routine maintenance and filter replacement.

Clamp-type Quick Open Closures are a popular solution across a wide range of industries due to their versatility, efficiency, and safety features. Their uses are as diverse as the sectors they serve, demonstrating their value and robustness.

Comparing Clamp Type Quick Open Closures and Other Types

Quick Open Closures are utilized in a variety of industrial applications, each with its own set of advantages and design features. While clamp-type closures are well-known for their efficiency and convenience of use, other types, such as thread-type and hinge-type closures, have their own set of advantages. Let’s look at how these types compare.

Closures of the Clamp Type

Clamp-type closures, as previously said, are praised for their quick and secure functioning. They are simple to use, require little physical effort, and frequently have safety devices to prevent accidental opening under pressure. These closures are adaptable and can survive tough industrial environments, making them ideal for high-pressure applications.

Threaded Closures

Threaded-type closures, also known as screw-type closures, consist of a threaded door that screws directly into the vessel. While they produce a secure seal, they often take longer and require more effort to open and close than clamp-type closures. Thread-type closures, on the other hand, can be a cost-effective option for tiny vessels or low-pressure applications.

Closures with hinges

Hinge-type closures have a hinge mechanism that allows the door to swing open, allowing simple access to the interior of the vessel. While they, like clamp-type closures, are quick to operate, they may not always be suited for high-pressure applications. Their design, on the other hand, allows for greater door sizes, which might be useful in situations requiring wide access points.

Why Clamp Type Over Others?

The choice between clamp and other forms of closures is mostly determined by the application’s specific requirements.

When quick and frequent access to the vessel interior is required, especially in high-pressure settings, clamp-type closures are typically recommended. Because of their ease of use, robustness, safety features, and capacity to endure high pressures, they are suited for a wide range of industries.

Thread-type closures, on the other hand, may be preferred for smaller vessels or lower-pressure applications where cost is a consideration. Hinge-type closures can be advantageous in applications needing large access points, although they are not always the best solution in high-pressure applications.

Conclusion

Clamp Type Quick Closures are essential in a variety of industries, ranging from oil and gas operations to food processing and pharmaceutical manufacturing. Their innovative design combines efficiency, safety, and use to provide quick and secure access to pressure vessels, pipelines, and tanks.

These closures’ advantages are compelling: their strong design for high-pressure and high-temperature settings, integrated safety systems, and speed and ease of operation all contribute to their widespread use in a variety of applications. They efficiently reduce downtime, improve safety, and boost operational efficiency, making them a better choice in certain instances than other forms of closures.

Looking ahead, the field of Quick Open Closures is expected to undergo significant advancements and breakthroughs. Improvements could concentrate on strengthening safety features, sealing materials and systems, and integrating smart technologies for monitoring and automation. These advances may provide even higher operational efficiency, safety, and dependability, reinforcing the necessity of Quick Open Closures in industrial processes.

Finally, the importance of clamp-type Quick Open Closures in modern enterprises cannot be emphasized. Their contribution to operational efficiency and safety is crucial, and they will continue to play an important role in industrial processes as technology advances.

Reviews

There are no reviews yet.