Description

Introduction

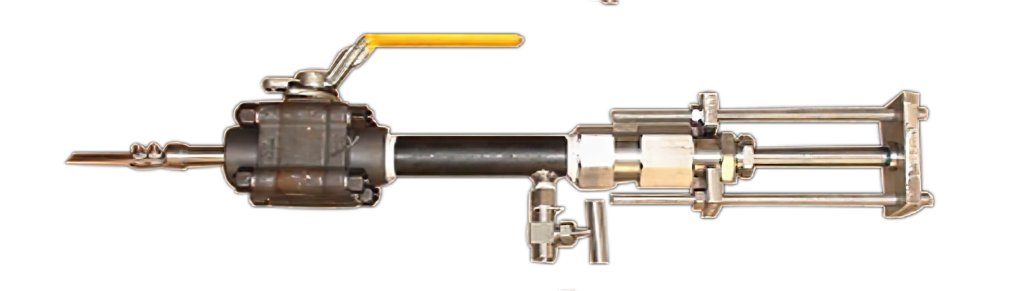

The EMT-RCC Retractable Corrosion Coupon System can operate at pressures up to 1,500 psi (10.3 MPa) and temperatures up to 500 °F/260 °C. The implantation depth of the corrosion coupon probe can be adjusted during operation, depending on the diameter and wall thickness of the pipeline. The system comes in standard lengths of 24, 30, 36, 42, and 48 inches to accommodate pipelines of varying diameters. At its extremity, the system can hold an insulated strip-type corrosion coupon. The system comprises a probe rod, a ball valve, a corrosion coupon, and an adjustable safety clamp kit. The use of the safety clamp is recommended when the pipeline pressure is below 1,500 psi and the temperature is below 500°F.

Retractable Corrosion Coupons are available in lengths of 18, 24, 30, and 36 inches to cater to a variety of applications. Designed to withstand high pressure and temperature conditions, these coupons have a pressure rating of up to 1,500 PSI or 10.3 MPa and a temperature rating of up to 500° F or 260°C. Constructed from 316 stainless steel, they provide superior corrosion resistance and durability. Furthermore, they meet the stringent requirements of NACE MR0175 and MR0103, ensuring their quality and dependability in various industrial environments.

Disassembly and Maintenance Inspection

Follow the procedures below when disassembling the coupon system from the pipe for maintenance inspection.

(1) Adjust the upper safety clamp to the valve-closed state.

Loosen the two bolts on the upper safety clamp, adjust the nuts to the distance L2 = 515~525mm, and then stop. As the nuts are loosened, the corrosion probe support rod will be pushed upwards when there is pressure inside the conduit. If the coupon support rod does not rise up as the nuts are loosened, check to see if it is jammed in order to prevent injury from a sudden burst caused by internal pressure.

Note: Two people can operate simultaneously to unscrew the nuts, or one person can alternately unscrew the nuts (alternate operation every 1 to 2 turns).

As the nuts are loosened, the corrosion coupon support rod should spring out due to the pipe’s internal pressure. If it does not, it should be immediately inspected and addressed to ensure safe operation.

(2) Shut Off the Valve

Turn the valve handle to its closed position. Before doing so, ensure that the distance L2 is between 515–525mm to avoid any damage or harm to internal components caused by a smaller L2 distance.

(3) Disassemble the Sealing Nut of the Coupon System

Secure the branch pipe (No. 4 in Figure 1) to the top of the valve using a spanner. Use a second wrench to rotate the sealing fastener counterclockwise. Once it’s loosened, twist it by hand to separate the sealing nut and the parts above it, then store them in a safe place. This operation requires two people. Now, you can detach the coupon system from the welded base and the tubing, completing the disassembly process.

(4) Dismantle the Corrosion Coupon

When disassembly of the corrosion coupon is needed, adjust the nuts on the upper safety clamp of the corrosion coupon device. Reduce the distance between the two safety clamps until the corrosion coupon and the nuts securing it extend fully from the sealing nut. The extension should be sufficient to allow disassembly of the nuts needed to service the corrosion coupon, as shown in Figure 5. Unscrew the nuts holding the corrosion coupon in place, remove the corrosion coupon, and carry out any required inspections or replacements.

Why Use Retractable Corrosion Coupons?

Retractable Corrosion Coupons offer a significant advancement over traditional corrosion monitoring methods. They provide real-time, continuous data, allowing for immediate response to changes in corrosion rates. This stands in sharp contrast to traditional methods, which often involve time-consuming processes and intermittent data collection.

One of the primary benefits of Retractable Corrosion Coupons is their ability to operate under extreme conditions. These coupons can handle temperatures and pressures of up to 500 °F (260 °C) and 1,500 psi (10.3 MPa). This means they can be used in harsh industrial settings where regular corrosion monitoring systems would not work.

Retractable Corrosion Coupons offer flexibility in application thanks to their adjustable implantation depth. This feature allows the system to adapt to various pipeline diameters and wall thicknesses, providing a tailored solution for each specific scenario. This adaptability is a significant improvement over traditional systems, which often require a one-size-fits-all approach.

Another advantage is the ease of maintenance and inspection. The coupon can be removed, inspected, and replaced without interrupting the pipeline operation, minimizing downtime and increasing operational efficiency. Traditional methods, on the other hand, often require pipeline shutdowns for inspection and maintenance, resulting in lost productivity and increased costs.

Constructed from 316 stainless steel, Retractable Corrosion Coupons offer superior corrosion resistance and durability. They meet the stringent requirements of NACE MR0175 and MR0103, which ensures their quality and dependability in various industrial environments. Traditional corrosion monitoring systems, on the other hand, may not meet these industry standards and could be susceptible to premature failure due to material degradation.

In summary, Retractable Corrosion Coupons represent a significant improvement over traditional corrosion monitoring methods. They provide real-time data, can withstand extreme conditions, offer flexible applications, and ensure easy maintenance and inspection, all while meeting industry standards for quality and dependability. By opting for this advanced solution, companies can effectively manage corrosion, extend the lifespan of their equipment, and improve overall operational efficiency.

Conclusion

The EMT-RCC Retractable Corrosion Coupon System presents a revolutionary approach to corrosion monitoring. Its ability to provide real-time, continuous data, coupled with its superior tolerance to extreme conditions, makes it a highly efficient solution for industries that grapple with corrosion issues. Its adjustable implantation depth, customizable lengths, and easy maintenance make it a flexible and convenient option for a variety of applications.

In comparison to traditional corrosion monitoring methods, Retractable Corrosion Coupons offer a multitude of benefits. They streamline the monitoring process, provide precise and timely data, and adapt to different pipeline specifications. By choosing this advanced solution, industries can significantly enhance their ability to manage corrosion, extend the life of their equipment, and improve overall operational efficiency.

In conclusion, the adoption of the EMT-RCC Retractable Corrosion Coupon System is a forward-thinking choice for industries seeking to improve their corrosion monitoring processes. It represents a significant step towards a safer, more efficient, and cost-effective approach to corrosion management.

Reviews

There are no reviews yet.