Description

Precautions for Storing Quick Closure

If a temporary storage location is needed for the Quick Closure plate or its container, ensure it is stored appropriately.

To protect the interior surface of the high neck of the board, including all machining and sealing surfaces, it is recommended to apply a thin layer of anti-rust protective wax or a similar protective material.

Remove the securing ring from the head cover. After this, apply a protective substance to the organically processed object’s surface. Finally, reinstall it into the head cover seal ring to prevent moisture from entering.

Before installing the sealing ring, remove any protective materials from the groove and sealing surface, and apply the antirust lubricant evenly on the surface.

1. Strategies to Mitigate Tension and Deformation

To ensure effective sealing, try to minimize the amount of deformation caused by welding, assembly, and post-weld heat treatment. Here are some suggestions:

- Do not place the branch pipe connection too close to the high-neck welding on a simple body. The nominal diameter of the branch pipe should be less than the distance between the welding edges.

- When the vessel branch pipe is connected, weld the seam from the high collar of the Quick Closure to its simple body. Also, remove the door cover for the blind plate before welding.

- Maintain a minimum preheating temperature of 209 degrees Celsius. However, consider the technical welding parameters of the welding process used.

- Use automated techniques for consistent heating, at least partially.

- When manually executing a metal arc procedure, a staggered welding sequence is mandatory.

- For a large blind plate with a fixed lifting lug, use temporary lifting lugs for mounting. Supporting the welding position might be beneficial.

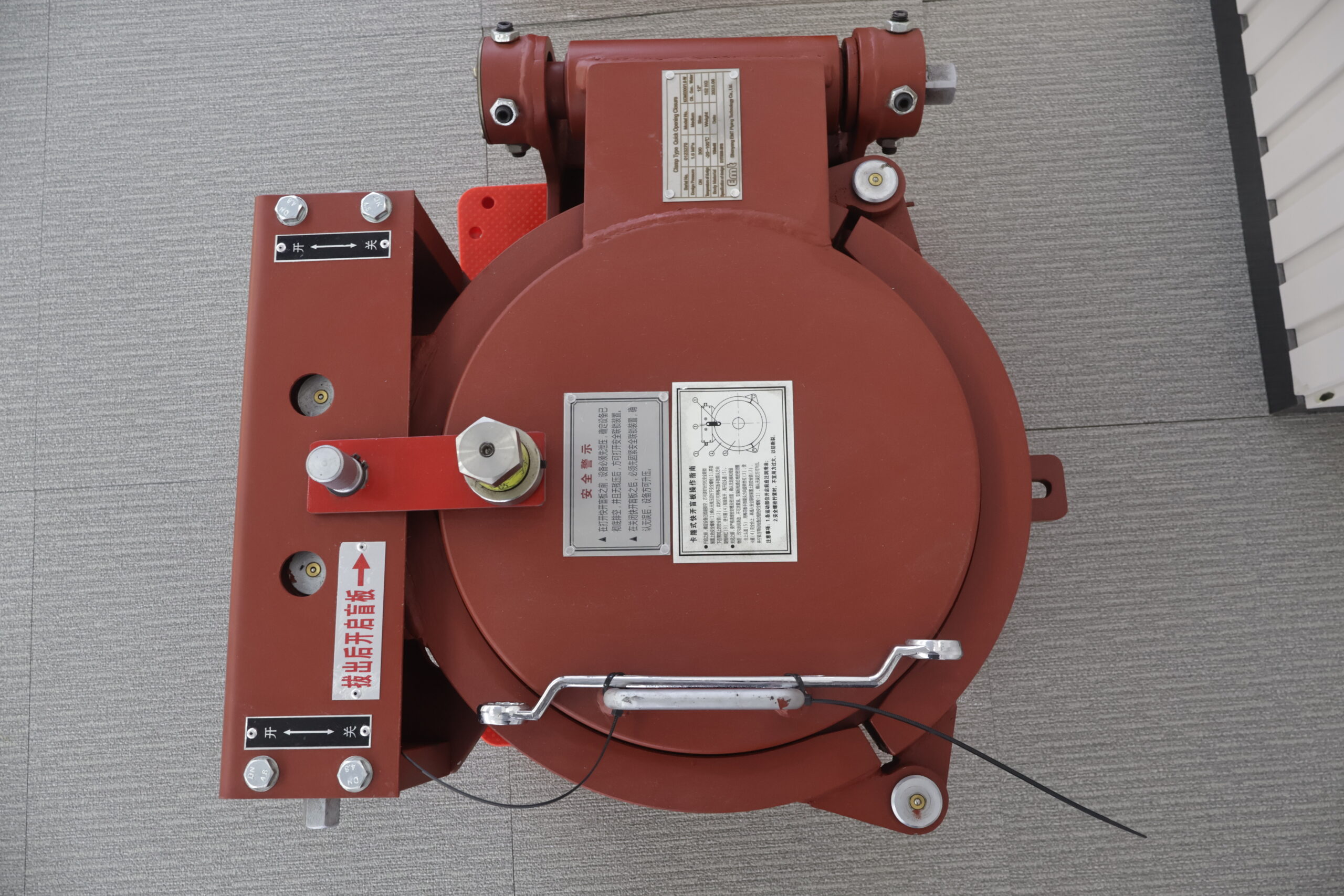

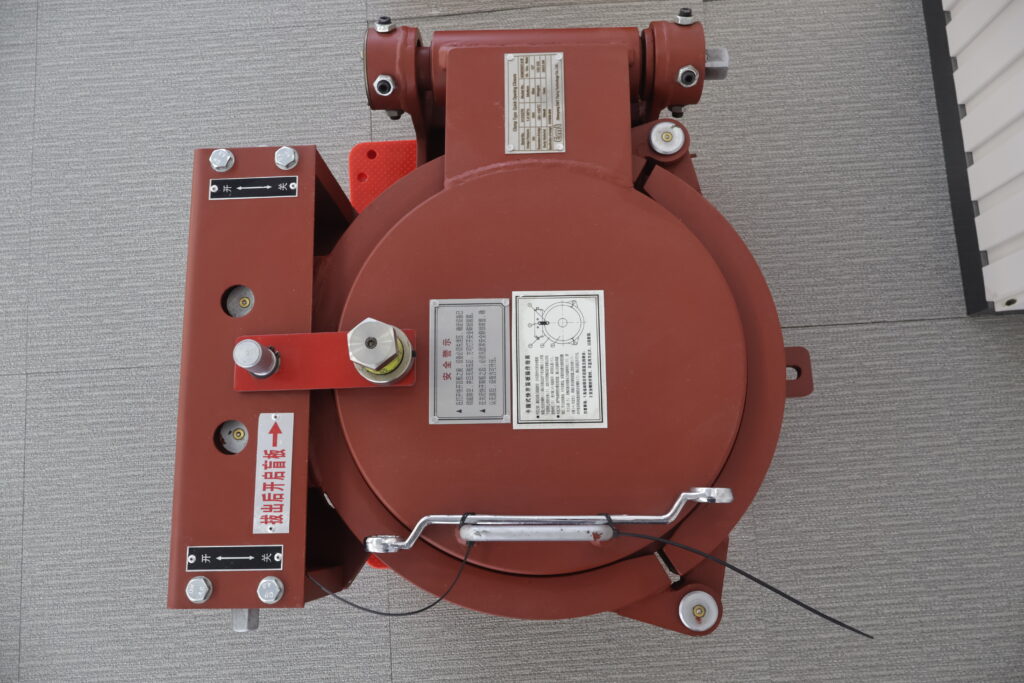

2. Maintenance

Ring lock adjustment

If the alarm fastener and ring lock are hard to operate, adjust the ring lock.

- Step 1: Install the alarm fastener after expanding the ring lock to its closed position. Alarm screws should be installed easily and secured tightly.

- Step 2: Rotate the locking draw plate by adjusting the eccentric sleeve between the shaft and eccentric sleeves.

- Step 3: Once the optimal position is found, secure the eccentric sleeve by tightening the Allen screw.

- Step 4: Verify operation by contracting and expanding the ring lock. If adjustments are needed, repeat the steps above.

Replacing the sealing ring

If necessary, remove the blind plate’s closure ring. Then carefully extract the sealing ring from the sealing cavity, avoiding damage to the sealing surface.

Clean the sealing cavity before unpacking the new sealing ring. Then, evenly distribute a thin layer of silicone lubricant.

Ensure the sealing ring has two radial corners before repositioning it within the sealing cavity. Insert the sealing ring into the top sealing cavity at the twelve o’clock position. Then, install it at the six, three, and nine o’clock positions. Install the remaining components evenly. Check if the sealing ring fits snugly into the center of the sealing cavity.

Finally, perform a hydraulic test. If the design pressure is 11 MPa or more, inspect the seal ring for faults after the test. Replace the sealing ring if damaged.

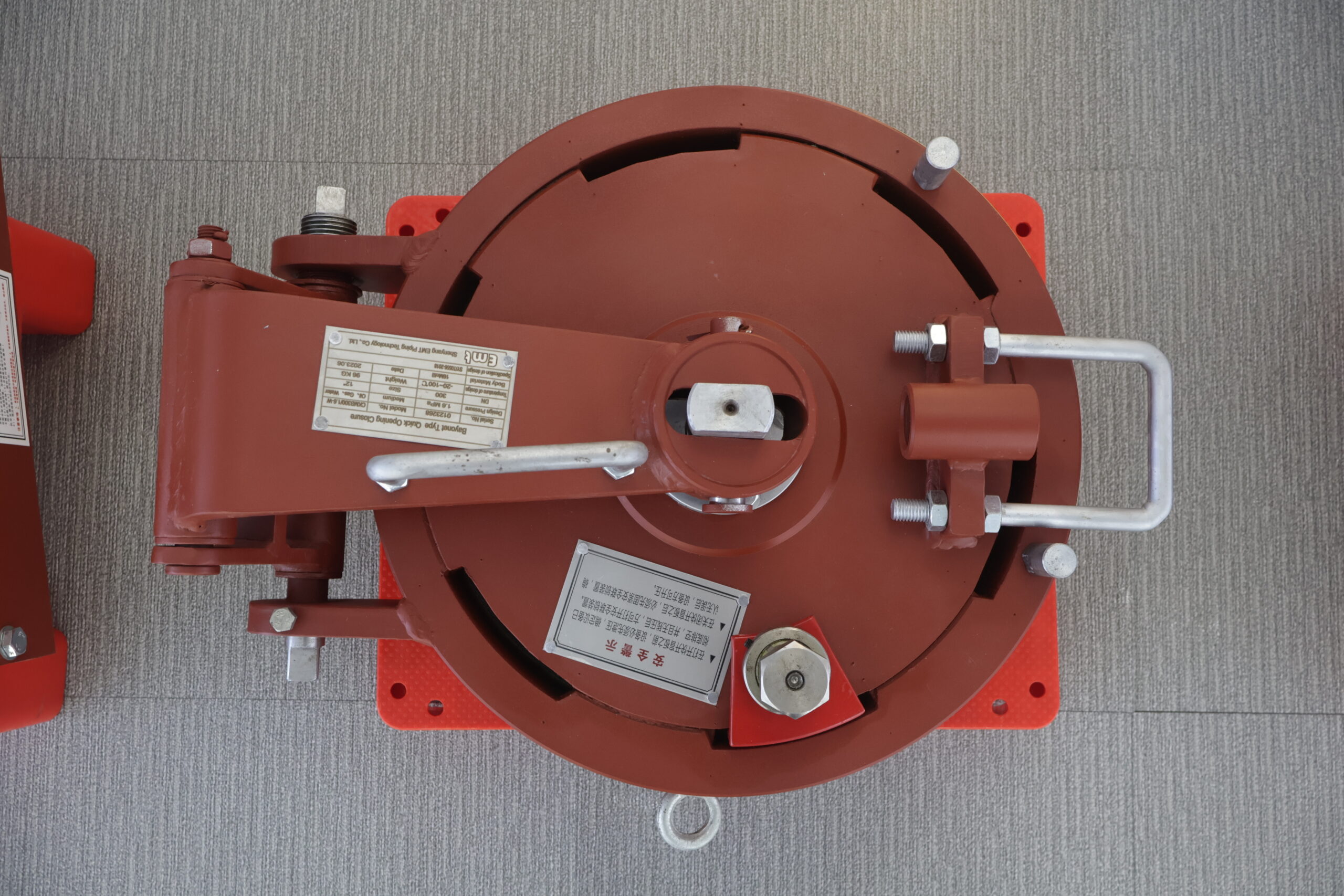

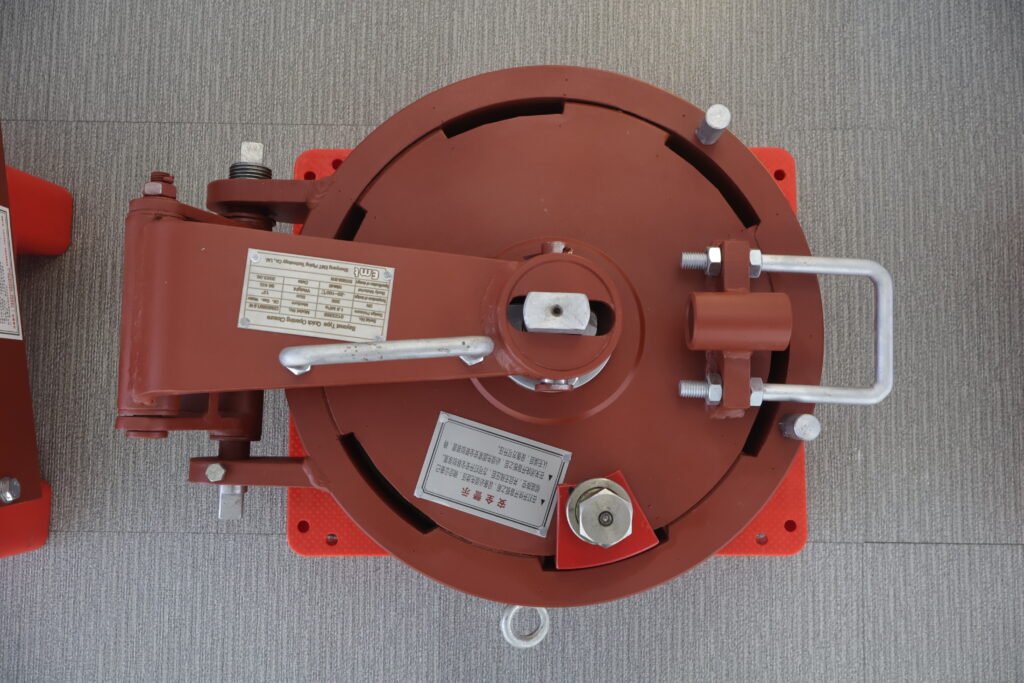

Working Process of Quick Closure

1. Examination and Preparation

(1) Conduct a thorough examination of the Quick Opening Closure and its associated elements for any signs of damage.

(2) Ascertain the position (open or closed) of each valve before the removal of the blind plate.

(3) The operator must ensure the launcher and receiver are free of natural gas and that the ball cylinder is not pressurized. In essence, the pressure indicator on the device should display zero.

(4) Prepare all necessary tools and ensure the vent valve is fully open.

2. Unlocking the Quick Closure

(1) Open the vent and blowdown valves of the pressure vessel.

(2) Once the cylinder pressure has been reduced to zero, proceed to remove the bleeder valve.

(3) By rotating the screw rod clockwise, the safety card can be removed, which in turn separates the pressure ring at a specific point.

(4) Carefully elevate the handle of the blind plate cover to completely disengage the teeth of the left and right pressure rings, providing access to the blind plate.

3. Securing the Quick Closure

(1) Once all debris on the sealing surface has been cleared, remove the sealing groove and handles of the upper and lower pressure rings.

(2) Apply an antirust lubricant, then push the blind plate cover fully into the press ring.

(3) Rotate the screw rod in the opposite direction.

(4) Insert the safety card and secure the cover.

(5) After tightening the vent valve, close the vent and blowdown valves of the pressure vessel.

Risk Analysis and Safeguard Procedures

Fault | Reason | Method |

Leakage at the blind plate seal | There is dirt on the groove, sealing surface, and O-ring surface. Aging of the sealing ring | Clean it up and install the seal |

Leak at safety interlock | There is dirt on the groove, sealing surface, and O-ring surface. The sealing ring is aging. | Clean it up and install the seal |

The blind cover and the blind seat are dislocated | Slewing mechanism parts are loose or displaced | Up and down dislocation: adjust the adjusting nut on the rotary hinge shaft; Dislocation from left to right: Adjust the positioning screw on the shaft sleeve |

Other faults | Contact the manufacturer to solve the question |

Our Service We offer a wide range of Quick Closure, each uniquely designed to meet different needs. To demonstrate the superior quality of our services, we provide samples for your review. Our commitment to customer service excellence is reflected in our prompt feedback. We pride ourselves on offering the quickest delivery times in the industry. Our online service operates 24 hours a day, 7 days a week, ensuring we’re always available to meet your needs.

Packing & Delivery Our choice of packaging is the PLYWOOD CASE, chosen for its numerous advantages. It is lightweight, with clear lines, providing insulation and high strength. Importantly, it is not prone to deformation. Plus, this packaging material requires no fumigation, making it a convenient choice for both us and our customers.

Transport For air transport, we have partnerships with many express companies, enabling us to help you select a courier company that offers competitive freight rates. For sea transport, we are advantageously located near Dalian Port in Shenyang. This proximity significantly reduces inland transportation costs and time, providing an efficient and cost-effective solution for shipping our products.

Reviews

There are no reviews yet.