Description

Introduction

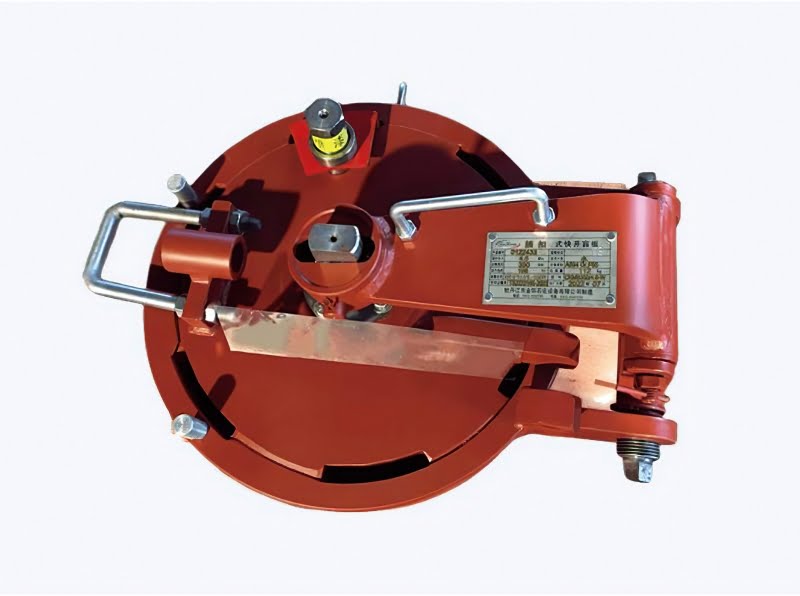

Pressure vessel quick-opening closures are fundamental components in a variety of industrial processes. These vessels are utilized in many industries, such as petrochemical, oil & gas, and power generation, among others. They play a vital role in containing and controlling high-pressure processes, making them essential for safe and efficient operations.

Importance of Pressure Vessel Quick Opening Closure

These pressure vessels are particularly important because of the quick-opening closures which allow for easy access during maintenance, inspection, or loading and unloading operations. Their design can significantly reduce downtime and increase the efficiency of industrial processes.

Potential Hazards Associated with These Vessels

However, despite their benefits, pressure vessels with quick-opening closures can pose significant hazards if not handled properly. These include the risk of explosions or accidental release of hazardous materials due to high pressure or temperature, faulty closures, or improper operation. Autoclave accidents are a prime example of such hazards.

Ensuring Safe Operation

Causes of Vessel Failures

Vessel failures can occur due to various reasons like material failure, design flaws, improper operation, or lack of maintenance. Understanding these causes can aid in developing measures to prevent them.

Measures to Ensure Safe Operation

Proper Design, Fabrication, and Inspection According to the ASME Code

Adherence to the ASME (American Society of Mechanical Engineers) code for the design, fabrication, and inspection of pressure vessels is crucial. The code provides guidelines to ensure that vessels can withstand high pressure and temperature without failure.

Adequate Foundations and Provisions for Thermal Expansion

Pressure vessels need to be installed on strong foundations to bear their weight, especially when filled. Additionally, provisions for thermal expansion are necessary to prevent structural damage due to changes in temperature.

Proper Operation and Maintenance

Regular maintenance and operation as per the manufacturer’s guidelines can prevent many potential failures. This includes timely inspection and replacement of worn-out parts.

Required Safety Devices

Installation of mechanical safety locking devices and pressure sensing devices can prevent accidental opening of the vessel under pressure and alert operators to any unsafe conditions, respectively.

Thorough Training of Operating Personnel

Operator training is crucial to ensure that pressure vessels are operated safely and efficiently. Operators should be trained in the operation, maintenance, and emergency procedures related to the equipment.

Conclusion

While pressure vessels with quick-opening closures bring efficiency and ease of access, their safe operation is paramount. Adherence to ASME codes, proper installation, regular maintenance, use of safety devices, and comprehensive training of personnel are key to minimizing risks and ensuring safe operation.

Reviews

There are no reviews yet.