Description

Pipeline pigging is very important for pipeline transportation. Pipeline Pigging is a complex project composed of multiple processes. The Pigging process consists of four steps: survey, demolition, cleaning, and maintenance. First of all, an on-site investigation is needed to determine the internal situation of the pipeline. Then work is needed to remove the sludge. Next comes the cleaning of the pipes. Finally, maintenance is carried out to prevent re-deposition. Pipeline desilting requires various technical support and professional equipment to ensure construction efficiency and work quality.

Cleaning Pigs are one of the most important pipeline pigging products. Emt is the manufacturer of many kinds of cleaning pigs. For example, mechanical cleaning pigs, solid cast pigs, ABS pigs, Fluoro rubber pigs, foam pigs, and so on.

Let’s take some pigs as an example to introduce.

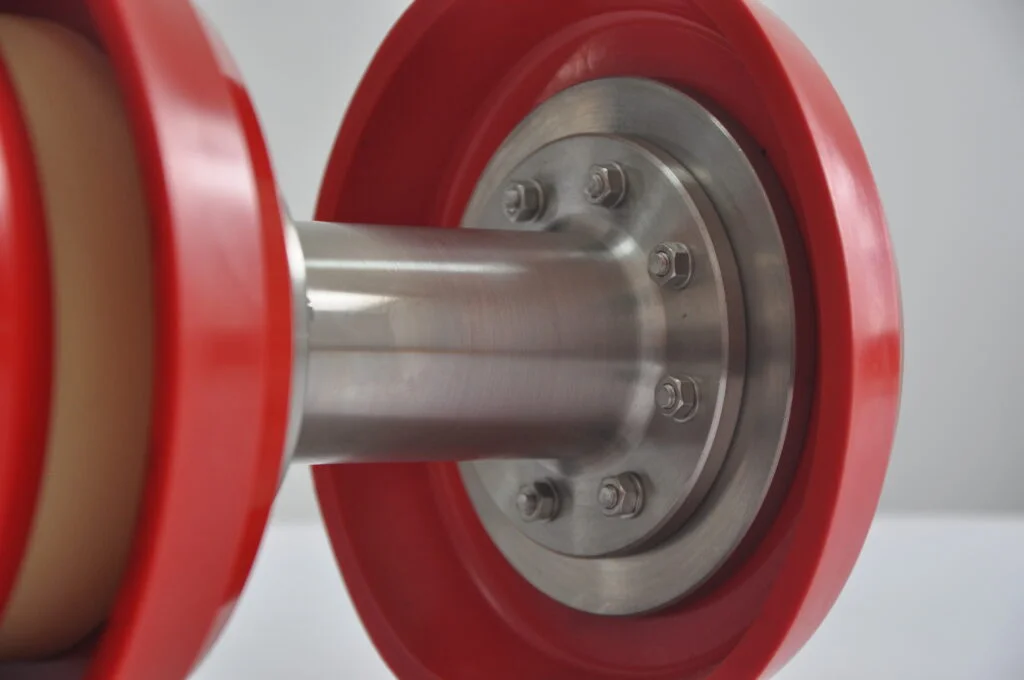

Mechanical Cleaning Pigs

A mechanical pig is a multi-purpose pigging device used to remove fluid buildup and solid impurities in a pipeline. It features a long service life, generally running 800 ~ 1000 kilometers, and can be installed with tracking equipment, caliper plate, magnets, etc.

Advantages of mechanical pigs include:

Comprehensive cleaning can not only remove the fluid in the pipe, but also effectively remove solid impurities.

Durability: Long service life, suitable for long distance pipelines.

Customizable: A steel brush, scraper, etc. can be installed as required to enhance the pigging effect.

However, mechanical pig also has some limitations:

Slightly poor passability: not suitable for pipelines with multiple elbows, valves and large deformation.

Not suitable for specific situations: The mechanical pig may not pass smoothly for pipes with multiple elbows, valves, and large deformations.

Foam Pigs

Foam pig is a cylinder made of foam rubber or foam with a conical head that is cross-wound at the tail or surface and coated with various wear-resistant scraping materials.

It is characterized by soft material, good elasticity, and an easy-to-pass elbow with a small curvature radius. It is mainly used for water removal and drying inside the pipeline. After installing other auxiliary equipment, it can remove impurities such as scale and corrosion products from the pipeline and is used for pipeline detection and tracking.

There are two kinds of conventional foam pigs: one is made of sponge products by processing, and the other is made of polyurethane material by mold.

The advantages of sponge products are simple processing, relatively low price, and good water absorption; The disadvantage is that it is easily broken and the effective running distance is short.

Polyurethane foam pig mold molding size is accurate, has good wear resistance, and has effective running distance is long; However, some problems require more molds, high production costs, and expensive raw materials.

Importance of Pipeline Pigging

Pipeline Pigging prevents clogging. Sediment, dirt, and debris in pipes can cause clogging. Regular cleaning ensures smooth water flow and avoids drainage problems.

Pipeline Pigging can extend the service life of the pipeline. The cleaning process can remove dirt from the pipe and prevent it from rusting the pipe material. This helps to extend the service life of the pipe.

Pipeline Pigging also ensures healthy water quality. The dirt and waste in the pipeline make it easy to breed bacteria, pests, and aquatic pests. Desilting can remove these contaminants and ensure healthy water quality.

Reason

If the pipeline is used for a long time, the solidification of mud and rust in the pipeline will make the diameter of the original pipeline smaller. The hydrogen sulfide gas produced by the sediment in the pipe will cause environmental pollution and easily cause an explosion. Acid and alkali substances in wastewater are easy to corrode pipe walls. Irregular removal of foreign matter in the pipe will cause blockage of the pipe. So pipe cleaning is crucial.

Meaning of Pipeline Pigging

The pipe will form a rolled skin when the raw material—steel pipe, steel plate, stainless steel, etc., is rolled. In the process of pipeline manufacturing, storage, transportation, and installation, impurities such as rust, welding slag, oil anti-rust agent, dust, sand, cement, and insulation materials will be formed. The above-mentioned impurities, such as rolling skin, rust, welding slag, rust inhibitor, and sand, seriously affect the normal use of the pipeline.

Methods

1. Chemical cleaning: Chemical cleaning pipes use chemical agents to clean the pipes. Temporary cleaning of the pipeline should be carried out chemically from the circulating pump stations at both ends of the pipeline. The technology has the characteristics of strong flexibility, no requirement on the shape of the pipeline, fast speed, and thorough cleaning.

2. High-pressure water cleaning: the high-pressure water jet above 50 MPa is used to peel and clean the dirt on the inner surface of the pipeline. This technology is mainly used for short-distance pipelines, and the pipe diameter must be greater than 50cm. This technology has the characteristics of being high-speed and low-cost.

3. PIG pigging: PIG industrial pigging technology relies on the driving force generated by the pump to push the fluid to drive the PIG (pig) forward in the pipe, and the dirt accumulated in the pipeline is discharged outside the pipe to achieve the purpose of cleaning. This technology is widely used in all kinds of process pipelines, oil and gas pipelines, and other cleaning projects, especially for long-distance fluid pipeline cleaning, with other technologies that cannot replace the advantages.

Reviews

There are no reviews yet.