Description

Introduction

For effective and secure fluid or gas delivery, pipeline maintenance is essential. Operational problems, environmental harm, and exorbitant expenses can all be avoided with routine maintenance. Pipeline Cleaning Pigs play a very important role in the maintenance of the pipelines.

The Need for Pipeline Cleaning

Regular pipeline cleaning is essential for many reasons, but it’s especially important for the effectiveness, security, and durability of the pipeline systems.

Pipelines can build up trash, sediment, and even chemical buildup if they aren’t regularly cleaned. This depends on the item being delivered. This accumulation may impede material flow, resulting in lower throughput and ineffective operation. In extreme circumstances, it could even result in total obstructions, necessitating expensive procedures and creating a large amount of downtime.

From a safety standpoint, corrosion and accumulation may cause the pipes’ structural integrity to deteriorate. Over time, this deterioration can result in leaks or even pipeline breaches, posing substantial environmental dangers and perhaps resulting in significant operational and reputational losses.

Last but not least, routine cleaning makes pipelines last longer. Debris buildup and the presence of corrosive substances can hasten wear and tear, necessitating more frequent and expensive repairs or replacements.

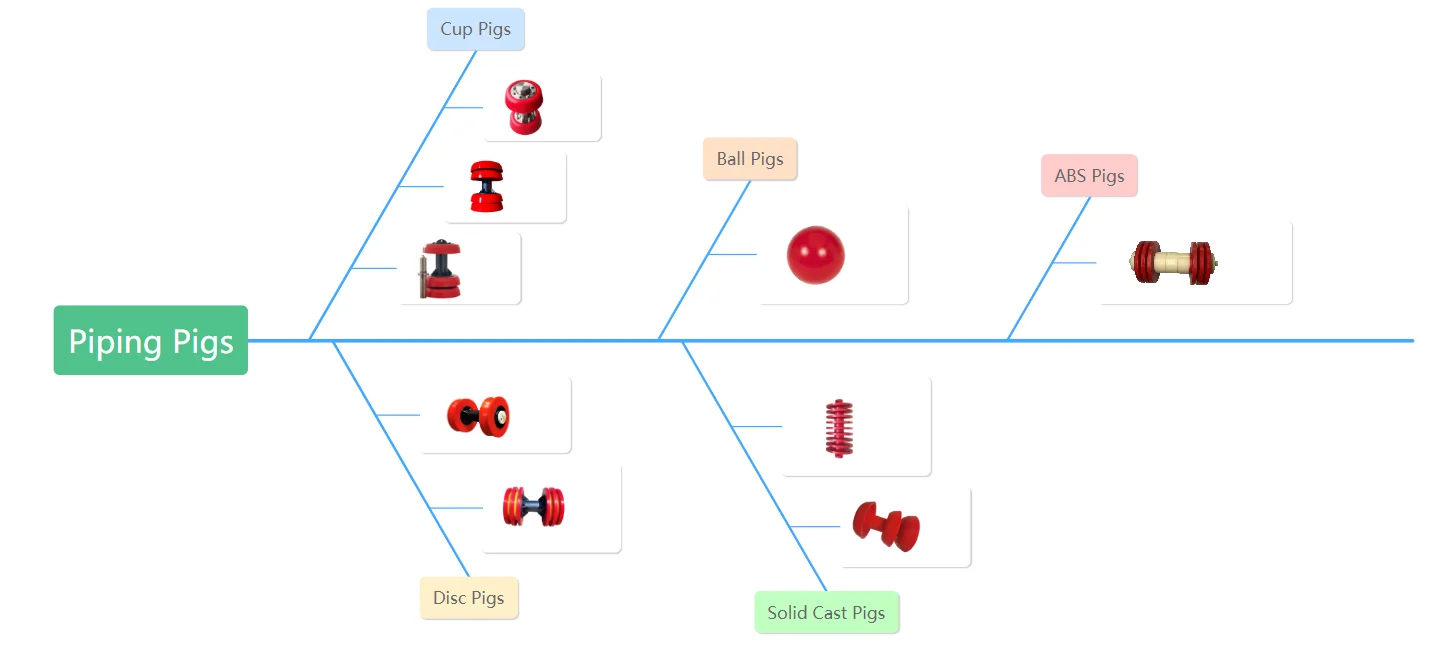

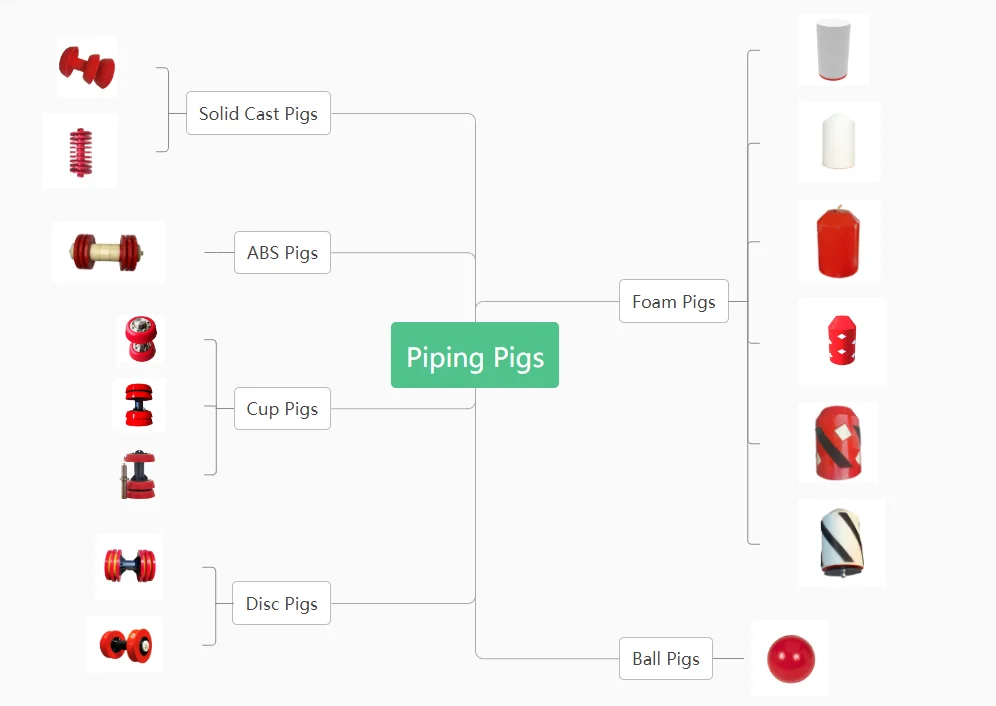

Types of EMT Pipeline Cleaning Pigs

We provide all of these pipeline cleaning pigs: Solid Cast Pigs, ABS Pigs, Foam Pigs, Cup Pigs, Disc Pigs, and Ball Pigs.

Advantages of Pipeline Cleaning Pigs

Solid Cast Pigs are robust and durable pipeline pigs, often used in challenging pipeline conditions. Thanks to their solid construction, they’re excellent at removing hard deposits and stubborn debris that other pigs might miss. Their durability provides a long life span, making them a cost-effective solution for regular pipeline cleaning and maintenance.

ABS Pigs also known as All-Body-Sphere pigs, ABS Pigs are lightweight and flexible, making them ideal for pipelines with bends, turns, or varying diameters. Their 360-degree cleaning surface ensures a thorough cleaning, and their light weight helps minimize wear and tear on the pipeline. Due to their versatility, ABS pigs are suitable for a wide range of cleaning applications.

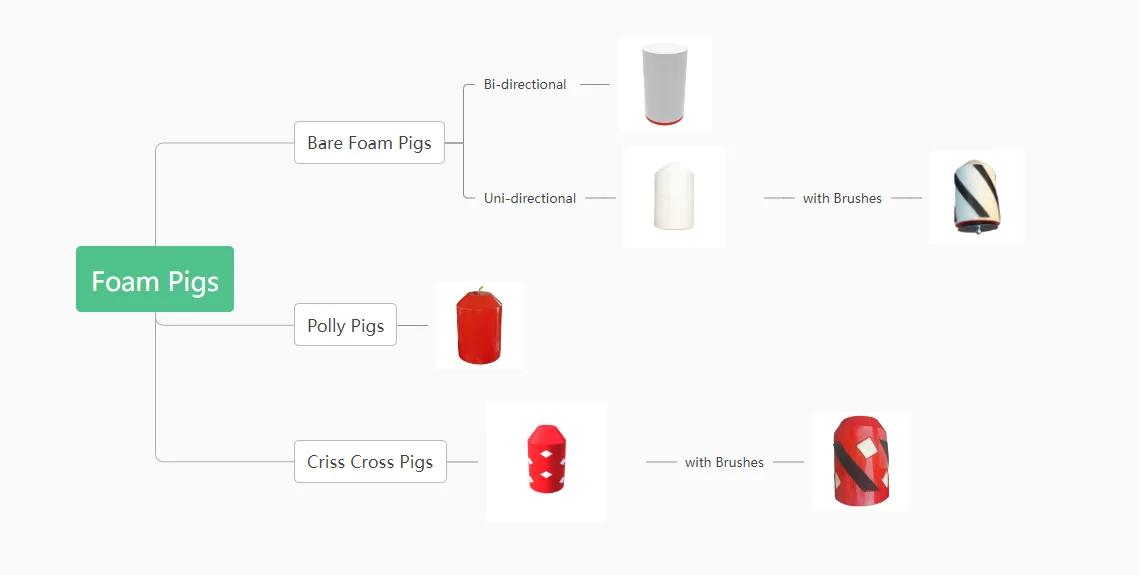

Foam pigs are versatile and economical, capable of traversing bends and fittings that may be challenging for other pig types. They are used for a variety of applications, such as drying, wiping, and removing loose debris. Foam pigs can be coated with abrasion-resistant material for more demanding cleaning tasks, enhancing their versatility.

Features of Pipeline Cleaning Pigs

Cup pigs are characterized by flexible, cup-shaped sealing elements. They create a seal against the pipeline wall, providing excellent cleaning and purging capabilities. Cup pigs can also be equipped with brushes or blades for more aggressive cleaning tasks. Their flexible design allows them to navigate diameter changes and bends effectively.

Disc pigs, named for their disc-shaped sealing elements, offer excellent seal and scraping capabilities. They can handle a range of pipeline conditions and cleaning requirements, from light cleaning to the removal of tough deposits. Their sturdy design allows them to maintain a consistent scraping force along the pipeline.

Ball pigs are simple, cost-effective, and good for light cleaning or product separation tasks. Their round shape allows them to easily navigate bends and turns in the pipeline. Though not as aggressive as other pig types, ball pigs are useful for routine maintenance and pre-inspection cleaning.

Summary

Summary

The importance of pipeline cleaning is further emphasized by describing how neglected pipes can suffer from chemical buildup, debris collection, and corrosion, which can lower throughput, pose safety hazards, and shorten lifespan.

Summary

Summary

Reviews

There are no reviews yet.