Description

Introduction

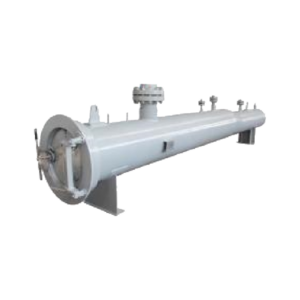

The Pig Launcher, a revolutionary device in the oil and gas industry, has transformed the way pipeline maintenance and cleaning are carried out. With its advanced design, superior functionality, and outstanding safety features, the pig launcher has become an indispensable tool for optimizing operations in the oil field. Let’s delve into the intricacies of this remarkable device and explore its numerous benefits.

Working Principle of Pig Launcher

At the core of the pig launcher lies its exceptional working principle, which ensures efficient pipeline cleaning and maintenance. The primary function of the pig launcher is to introduce cleaning pigs into the pipeline. These pigs, propelled by the pressure of the fluid, travel through the pipeline, effectively removing contaminants, debris, and deposits along the way. This process, known as pigging, plays a vital role in maintaining the integrity and operational efficiency of the pipeline.

The pig launcher operates by inserting the cleaning pig into the pipeline through the launcher itself. Once the pig is inside, it moves along with the flow of the fluid, effectively scraping away unwanted materials from the pipeline’s walls. This process significantly improves the pipeline’s flow capacity, reduces the risk of blockages, and ensures the smooth transportation of oil, gas, or other fluids.

Central to the operation of many pipeline systems lies a crucial component, the pig launcher. This device’s exceptional working principle ensures thorough cleaning and maintenance of pipelines, which is essential for preserving the pipeline’s integrity and efficiency.

Functionality of Pig Launcher and Receiver

The primary function of the pig launcher is to facilitate the introduction of cleaning pigs into the pipeline system. These cleaning pigs, which are specially designed tools, are then set into motion within the pipeline. Propelled by the pressure of the fluid being transported, they embark on their journey along the length of the pipeline.

As they move, these cleaning pigs perform an essential task – they effectively remove contaminants, debris, and deposits that may have accumulated on the inner surfaces of the pipeline. Over time, these substances can cause a host of problems, from reduced flow capacity to increased risk of corrosion and blockages. By dislodging and removing these materials, the cleaning pigs help maintain the pipeline’s operational efficiency.

This process, known as pigging, plays a vital role in pipeline maintenance. It not only ensures the cleanliness of the pipeline but also contributes to preserving its structural integrity. Regular pigging can help prevent the development of problems that could compromise the pipeline’s safety or functionality.

The operation of the Pig Launcher

The operation of the pig launcher commences with the insertion of the cleaning pig into the pipeline. This is accomplished using the launcher itself, which acts as a sort of gateway for the cleaning pig. Once the cleaning pig is securely inside the pipeline, the flow of the fluid being transported allows it to move along the pipeline’s length.

As the cleaning pig travels through the pipeline, it effectively scrapes away unwanted materials from the pipeline’s interior walls. This could include various types of contaminants, from scale and sediment to more harmful substances. The cleaning pig, with its robust construction and design, ensures that these materials are effectively dislodged and removed.

This cleaning process significantly improves the pipeline’s flow capacity. By removing obstructions from the pipeline’s interior, the cleaning pig helps restore the pipeline’s original capacity. This ensures that the flow of fluids, whether oil, gas, or other substances, remains smooth and efficient.

Design Conditions

| Design Conditions | ||

| 1. | Pipeline Size | From 6″ up to 56″ |

| 2. | Design Code | ASME VIII Div 1; ASME B31.3; ASME B31.4; ASME B31.8, etc. |

| 3. | Design Factor | 0.5, 0.6, 0.7, etc. |

| 4. | Corrosion Allowance | 0-5mm or more |

| 5. | Design Pressure | CL150, CL300, CL600, CL900, CL1500, CL2500, or as required. |

| 6. | Design Temperature (Min/Max) | -50℃ / 200℃ |

| 7. | Closure Type | Clamp Ring Type Quick Opening Closure |

| 8. | Installation Orientation | Horizontal, Vertical, Inclined |

| 9. | Applicable Medium | Gas, Oil, Petroleum, Chemical Materials, Water, etc. |

| Structure and Main Materials | ||

| 1. | Major Barrel/Min Barrel | ASTM A106, ASTM A516 Gr.70, or as required. |

| 2. | Quick Opening Closure (with Interlock System) | ASTM A515 Gr.70, ASTM A516 Gr.70, And ASTM A105, ASTM A350 LF2 Class1, ASTM A694 F42 F46 F48 F50 F52 F56 F60 F65 F70, or as required. |

| 3. | Sealing Ring for the Closure | Viton, Nitrile |

| 4. | Saddle Support | Q235, or as required. |

| 5. | Flange | ASTM A105, ASTM A694 F70, or as required. |

| 6. | Lifting Lug/Eyes | Q235, or as required. |

| 7. | Grounding | Yes |

| 8. | Name Plate | Stainless Steel, or as required. |

| Certificates | ||

| 1. | ASME U Stamp Certificate | Applicable |

| 2. | Third-Party Inspection | BV, SGS, ABS, DNV, or as required. |

Reviews

There are no reviews yet.