Description

With most domestic refining and chemical enterprises’ equipment, corrosion problems have become increasingly prominent, and corrosion protection and monitoring are becoming more and more important. The EMT Online Resistance Probe and Coupon Corrosion Monitoring System plays an important role in monitoring the corrosion rate of the pipe system.

Corrosion monitoring technology can continuously measure the corrosion rate of equipment and some related parameters. It will not affect the normal operation of the production system. It has been rapidly developed in domestic petroleum refining enterprises. The resistance corrosion probe is a fast, sensitive, convenient, and continuous corrosion measurement tool. The tool has been widely used in China’s oil refining system since the 1960s. At present, the measuring instrument has evolved from portable manual measurement to automatic recording, which can be used as online monitoring.

Inductance probe monitoring technology is a new online corrosion measurement technology after 2000. It has the characteristics of high sensitivity, fast response, strong anti-interference, wide applicability, etc. At present, it has been widely and successfully applied in China. Under the same principle, measurement test pieces can be made into various shapes to adapt to different application environments.

Working principle

The working principle of the Corrosion Monitoring System is as follows:

It is an effective method to indirectly monitor the corrosion of equipment. Based on the measurement of metal corrosion loss, the corrosion loss rate is calculated by measuring the change in AC signal caused by the corrosion thinning of the corrosion test piece.

When the measuring element inserted in the pipeline is corroded, the reduction of its cross-sectional area will cause the AC signal to change. The AC signal is applied to the measuring test piece. The thinning amount and corrosion rate of the measuring element are calculated through the change of the AC signal. When measuring elements share material properties with the equipment, they can have similar corrosion states. Thus, the element’s corrosion rate can approximate the equipment’s rate. Usually, the measurement resolution of the inductance probe is 30nm, the annual corrosion rate is 0.254 mm/a, and the corrosion thinning amount of 1 hour can be distinguished. The general service life (maximum loss) is 0.25mm.

High-precision Resistance Probe

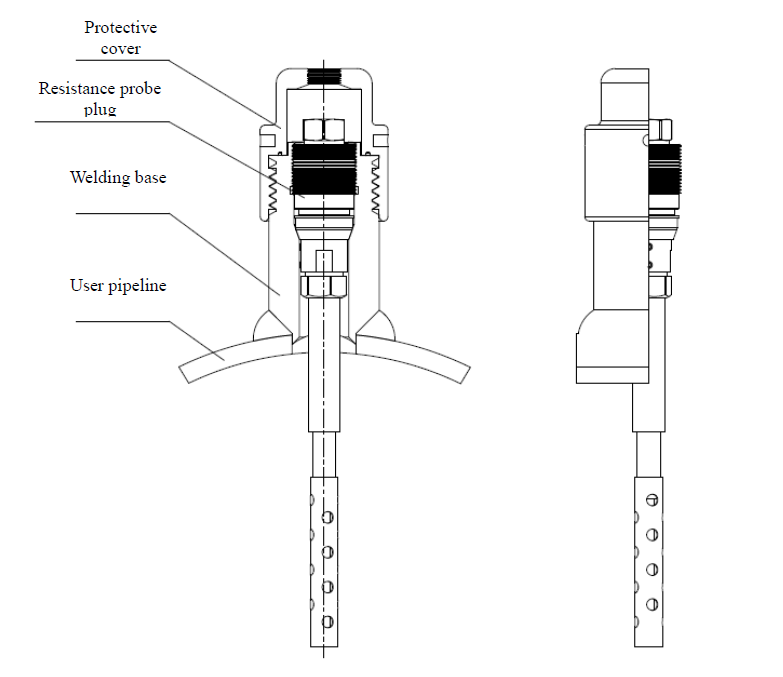

1. A high-precision resistance probe is a retrievable and highly sensitive corrosion probe suitable for various corrosion monitoring systems. The sensitive components of the fully welded structure make the probe properly applicable to a variety of harsh environments.

2. The probe assembly includes a probe body equipped with monitoring test pieces, which are locked with a radial seal when connected to the low-pressure stuffing box; when connecting to the high-pressure hollow plug, tighten it to the left with the threaded connection seat; all its components are sealed by fusion welding. A flow rate protection cap is optional for some probe measurement test pieces.

3. When installed in a high-pressure environment, the probe connection seat is connected to the hollow plug, allowing for installation and disassembly under pressure. Pressurized operations can be carried out using retrieval tools without affecting production to complete probe installation and retrieval.

Main performance features include:

Online Resistance Probe and Coupon Corrosion Monitoring System

1. Measurement accuracy of the analyzer: Resolution: 18 bits = 1/262144 (i.e., when the corrosion thickness at the measuring part of the corrosion probe is 0.254 mm = 20 mils, divide 0.254mm into 262144 parts, 0.96nm for each)

2. Reaction accuracy of the analyzer: 10nm

3. Impedance range of probe test piece: 1~50 milliohms

4. Power supply: 24VDC power supply/lithium battery

5. Current consumption: 12mA@24VDC/1~12mA@8.4V

6. Communication: RS485 bi-wire, 2400 baud rate/2.4G, LORA, 4G/5G

7. RS485 Address: 0~31

8. Ambient temperature: -40℃~+70℃

9. Casing protection grade: IP 65

10. Max collection rate: 1 time/ minute

11. Min collection rate: 1 time/ arbitrarily

12. Hazardous area certification: Ex d IICT4 Gb

13. Power of wired collector: 0.5W

Reviews

There are no reviews yet.